Heat treatment method of low-carbon low-alloy vanadium-titanium microalloyed ultra-high strength cold-rolled steel sheet

A cold-rolled steel sheet and micro-alloying technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of insufficient elongation and high strength of cold-rolled steel sheets, and achieve the effects of increased elongation and high dislocation density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

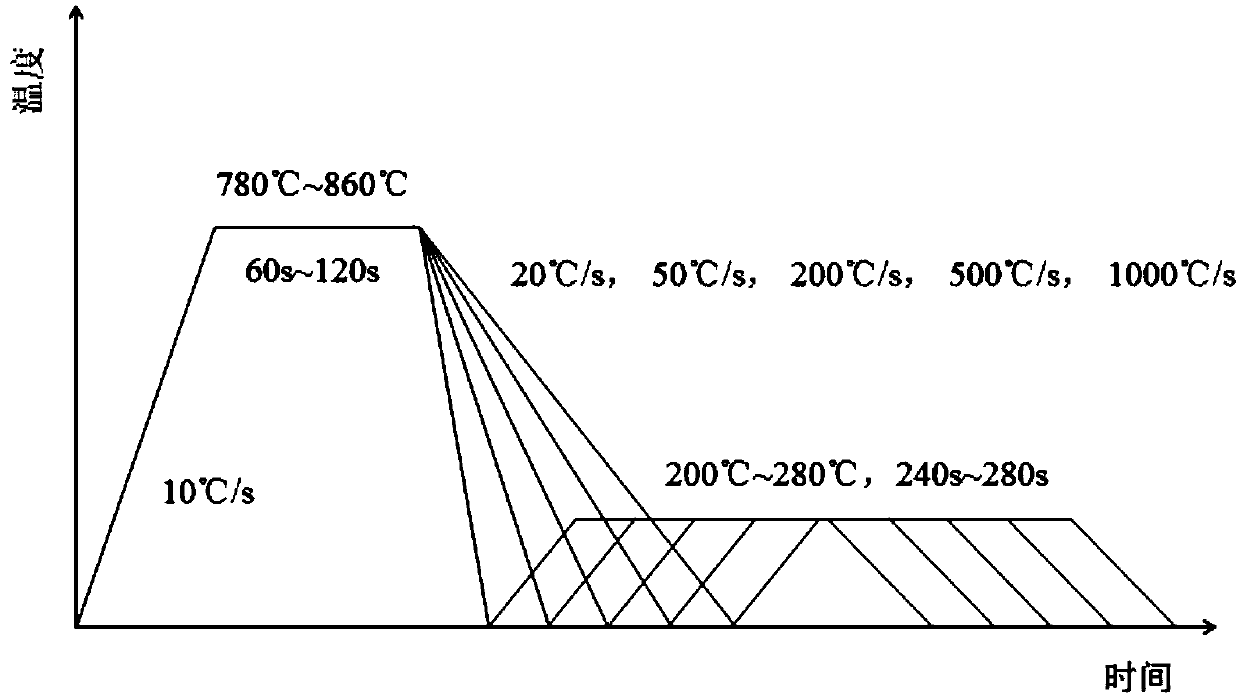

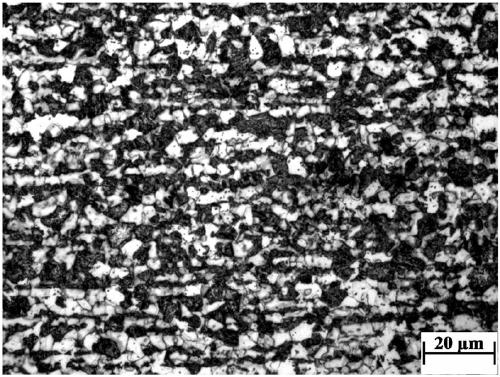

[0028] The mass percentages of the elements of the cold-rolled steel sheet used in Example 1 are: carbon 0.15%, silicon 0.4%, manganese 1.9%, titanium 0.026%, vanadium 0.08%, and the balance is iron. The specific implementation method is as follows: first, heat the cold-rolled steel plate at a rate of 10 °C / s to 840 °C in the two-phase zone for 80 seconds, then use high-speed gas jet cooling to cool to room temperature at a cooling rate of 20 °C / s, and then heat it at 10 °C / s speed heating to 280°C for 280s for overaging treatment, then air cooling to room temperature.

[0029] The beneficial effect of this embodiment is: after heat treatment, the tensile strength of the cold-rolled steel plate is 926MPa, the yield strength is 452MPa, and the elongation reaches 14.8%. Although the tensile strength has decreased to a certain extent, the elongation has been greatly improved, and the toughness of the cold-rolled steel plate has been improved.

Embodiment 2

[0031] The mass percentages of the elements of the cold-rolled steel sheet used in Example 2 are: carbon 0.12%, silicon 0.8%, manganese 2.0%, titanium 0.031%, vanadium 0.08%, and the balance is iron. The specific implementation method is as follows: first, heat the cold-rolled steel plate at a rate of 10 °C / s to 840 °C in the two-phase zone for 80 seconds, then use high-speed gas jet cooling to cool to room temperature at a cooling rate of 50 °C / s, and then heat it at 10 °C. / s speed heating to 280°C for 280s for overaging treatment, then air cooling to room temperature.

[0032] After the heat treatment in Example 2, the tensile strength of the cold-rolled steel sheet is 970 MPa, the yield strength is 498 MPa, and the elongation reaches 13.5%.

Embodiment 3

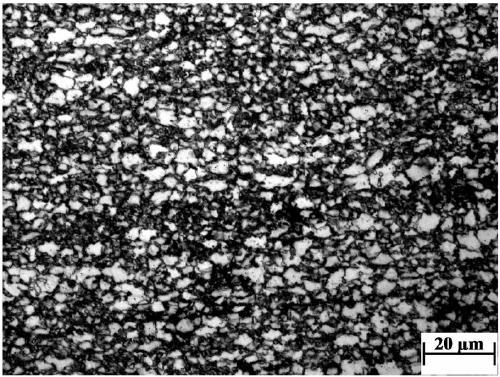

[0034] The mass percentages of the elements in the cold-rolled steel sheet used in Example 3 are: carbon 0.11%, silicon 0.9%, manganese 1.7%, titanium 0.035%, vanadium 0.06%, and the balance is iron. The specific implementation method is as follows: first, heat the cold-rolled steel plate at a rate of 10 °C / s to 840 °C in the two-phase zone for 80 seconds, then use 90 °C water quenching to cool to room temperature at a cooling rate of 200 °C / s, and then heat it at 10 °C / s speed heating to 280°C for 280s for overaging treatment, then air cooling to room temperature.

[0035] After the heat treatment in Example 3, the tensile strength of the cold-rolled steel plate is 1072MPa, the yield strength is 701MPa, and the elongation reaches 10.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com