Preparation method of prussian-blue compound ammonium removal material, and application of prussian-blue compound ammonium removal material in removing ammonium from sewage

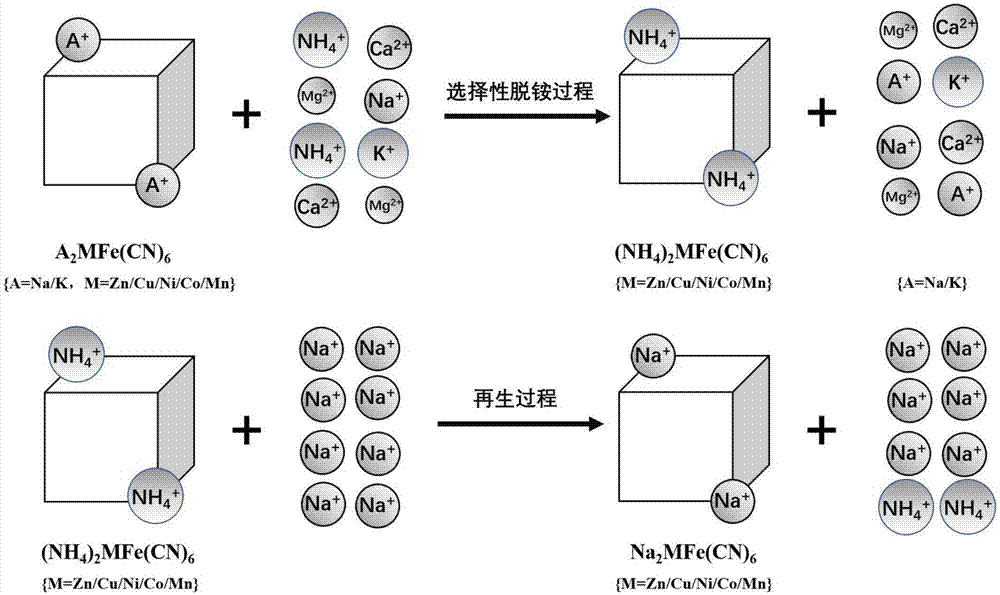

A Prussian blue and compound technology, which is applied in the field of preparation of Prussian blue compound deammonium materials, can solve the problems of affecting the normal operation of the project, poor ammonium ion selectivity, low adsorption capacity, etc. , the effect of improving adsorption selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

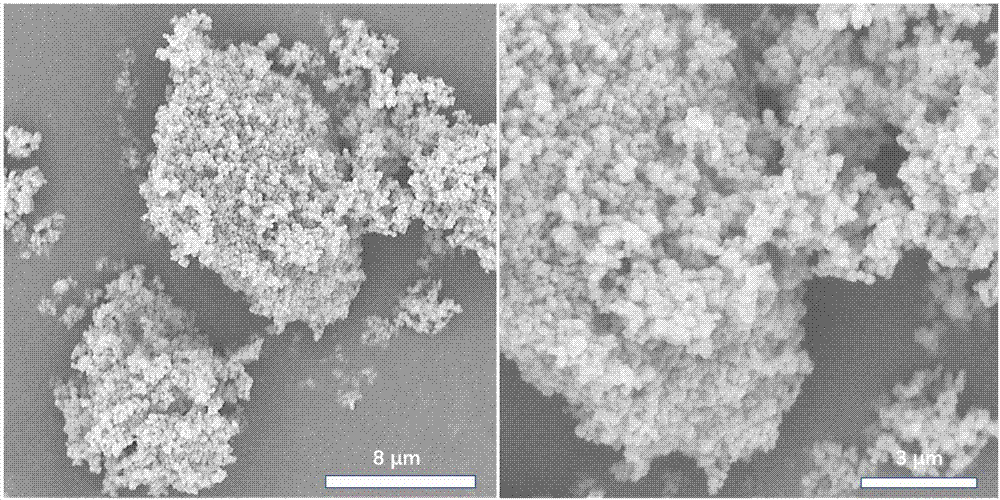

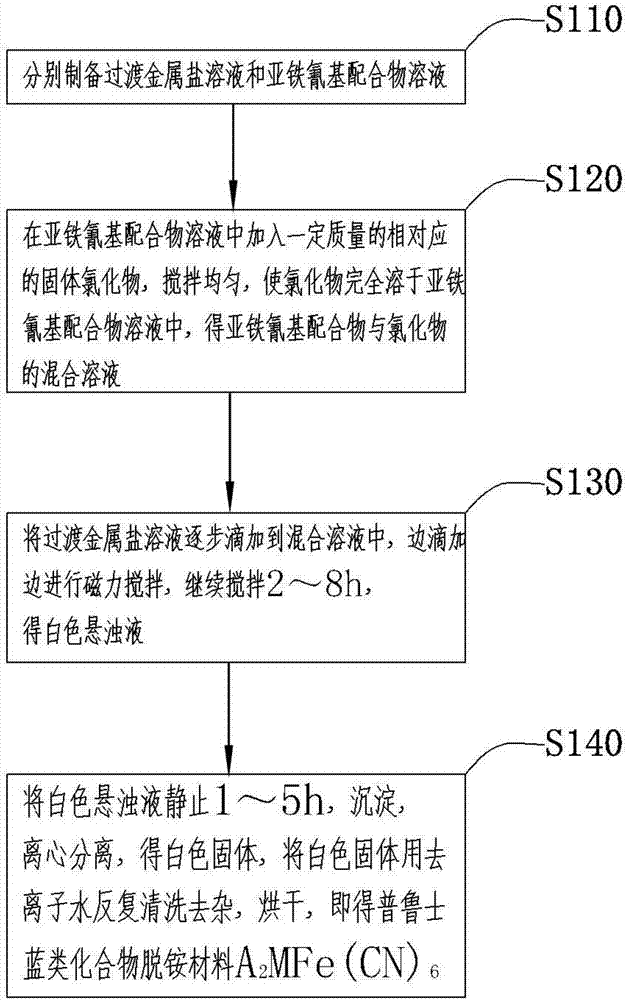

[0047] Weigh 0.2 mol of zinc chloride, dissolve it in 200 ml of deionized water, stir evenly to obtain a zinc chloride solution with a substance concentration of 1 mol / L; weigh 0.2 mol of Prussian blue sodium ferrocyanide, and dissolve Stir evenly in 200ml of deionized water to obtain a sodium ferrocyanide solution with a substance concentration of 1mol / L; add 0.1 mol of solid sodium chloride to the sodium ferrocyanide solution and stir evenly to make Sodium chloride is completely dissolved in the sodium ferrocyanide solution to obtain a mixed solution of sodium ferrocyanide and sodium chloride; the zinc chloride solution is added dropwise to the mixed solution, and magnetic stirring is performed while adding dropwise. After completion, continue to stir for 2 hours to obtain a white suspension; leave the white suspension to stand still for 1 hour, precipitate, and centrifuge to obtain a white solid; wash the white solid with deionized water several times to obtain the Prussian b...

Embodiment 2

[0049] Weigh 0.6 mol of copper chloride, dissolve it in 200 ml of deionized water, and stir evenly to obtain a copper chloride solution with a substance concentration of 3 mol / L; weigh 0.6 mol of Prussian blue sodium ferrocyanide and dissolve Stir evenly in 200ml of deionized water to obtain a sodium ferrocyanide solution with a substance concentration of 3mol / L; add 0.6 mol of solid sodium chloride to the sodium ferrocyanide solution and stir evenly to make Sodium chloride is completely dissolved in the sodium ferrocyanide solution to obtain a mixed solution of sodium ferrocyanide and sodium chloride; the copper chloride solution is added dropwise to the mixed solution, and magnetic stirring is performed while adding dropwise. After completion, continue stirring for 4 hours to obtain a white suspension; leave the white suspension for 3 hours, precipitate, and centrifuge to obtain a white solid; wash the white solid with deionized water several times to obtain the Prussian blue ...

Embodiment 3

[0051] Weigh 0.1 mol of nickel sulfate, dissolve it in 200 ml of deionized water, and stir evenly to obtain a nickel sulfate solution with a substance concentration of 0.5 mol / L; weigh 0.2 mol of Prussian blue potassium ferrocyanide and dissolve it Stir evenly in 200ml of deionized water to obtain a potassium ferrocyanide solution with a substance concentration of 1 mol / L; add 0.8 mol of solid potassium chloride to the potassium ferrocyanide solution and stir evenly to make chlorine Potassium is completely dissolved in the potassium ferrocyanide solution to obtain a mixed solution of potassium ferrocyanide and potassium chloride; the nickel sulfate solution is added dropwise to the mixed solution, and the addition is performed while magnetically stirring. After the addition is complete Continue stirring for 6 hours to obtain a white suspension; leave the white suspension to stand for 4 hours, precipitate, and centrifuge to obtain a white solid; wash the white solid with deionize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com