Mesoporous Ag/Ag2O/TiO2 solid microsphere material preparation method

A solid and mesoporous technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve the problem of reduced photocatalytic effect of composite catalysts and achieve catalytic reaction promotion , good repeatability, the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

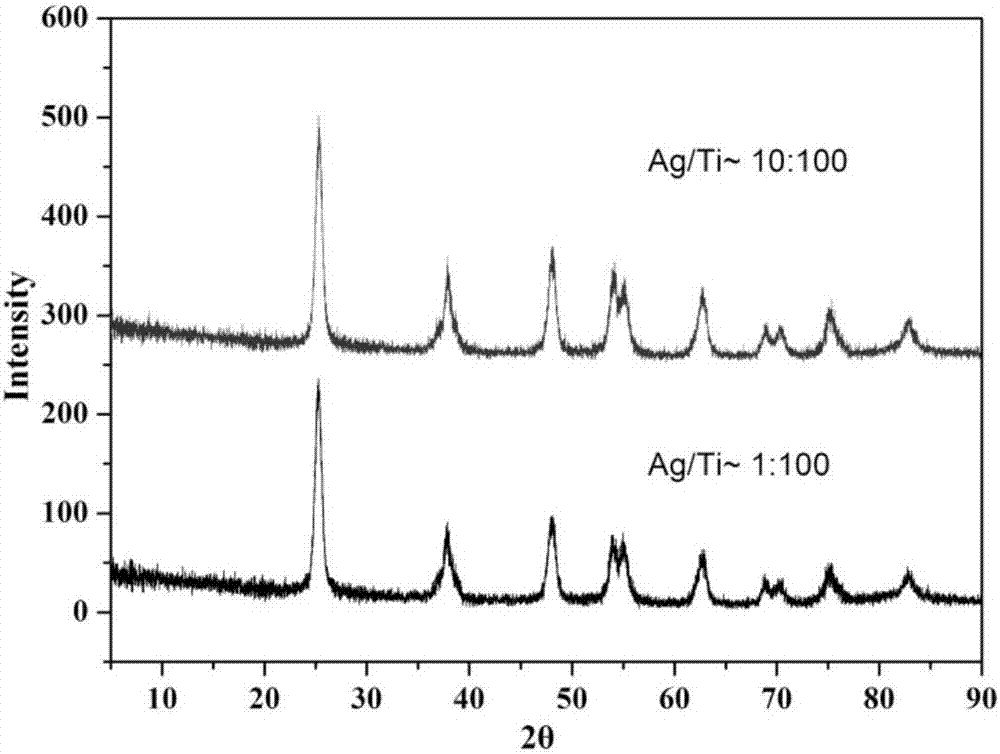

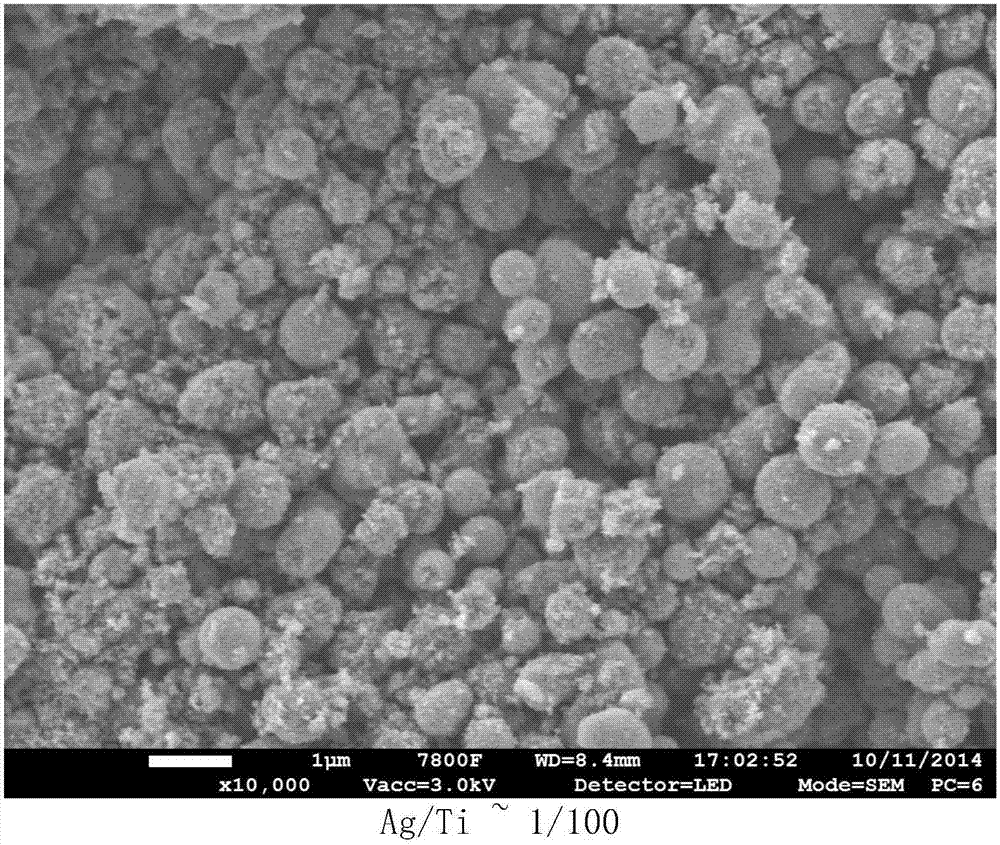

Embodiment 1

[0031] At room temperature, fully dissolve 1.98g hexadecylamine in 200mL ethanol solution (98wt%), adjust the magnetic stirrer rotation speed to 500rpm, add 2mL silver nitrate solution, add 1.6mL deionized water at the same time, finally turn down the magnetic stirrer Rotate to 200rpm, quickly add 4.455mL of titanium isopropoxide, so that the molar ratio of Ag and Ti in the solution is 1 / 100, after stirring for 30s, the solution is left to settle for 18h. The product and solution were washed 3 times with ethanol and deionized water, dried and ground. Transfer the powder to a 100mL stainless steel high-temperature and high-pressure reactor with polytetrafluoroethylene lining, add 40mL ethanol and 20mL water, place it in a muffle furnace for hydrothermal reaction at 160°C for 18h, and then cool to room temperature to obtain the product Wash with water and absolute ethanol three times respectively to remove possible residual impurities, centrifugally filter, and vacuum-dry at 60°...

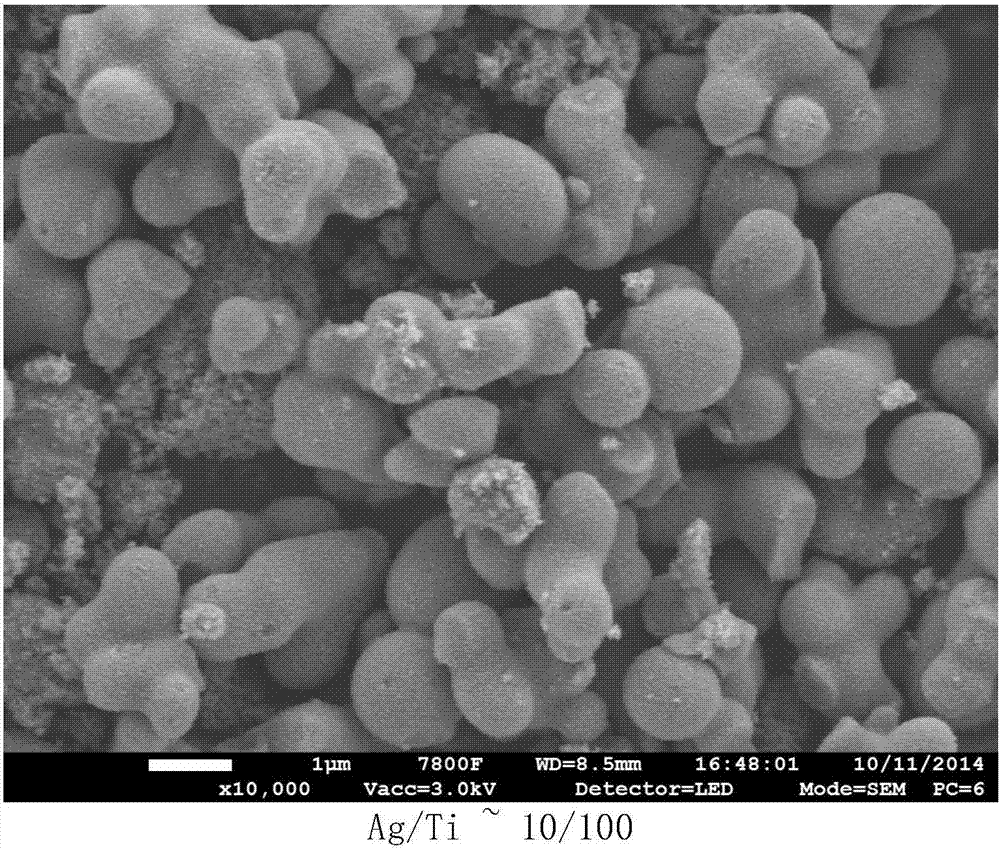

Embodiment 2

[0033] At room temperature, fully dissolve 1.98g hexadecylamine in 200mL ethanol solution (98wt%), adjust the magnetic stirrer rotation speed to 500rpm, add 20mL silver nitrate solution, add 1.6mL deionized water at the same time, and finally turn down the magnetic stirrer Rotate to 200rpm, quickly add 4.05mL titanium isopropoxide solution, so that the molar ratio of Ag and Ti in the solution is 10 / 100, after stirring for 30s, the solution is left to settle for 12h. The product and solution were washed 3 times with ethanol and deionized water, dried and ground. Transfer the powder to a 100mL stainless steel high-temperature and high-pressure reactor with a polytetrafluoroethylene liner, add 30mL ethanol and 30mL water, place it in a muffle furnace for hydrothermal reaction at 160°C for 18h, and then cool to room temperature to obtain the product Wash with water and absolute ethanol three times respectively to remove possible residual impurities, centrifugally filter, and vacuu...

Embodiment 3

[0035]At room temperature, fully dissolve 1.98g hexadecylamine in 200mL ethanol solution (98wt%), adjust the rotation speed of the magnetic stirrer to 500rpm, add 0.2mL silver nitrate solution, add 1.6mL deionized water at the same time, and finally turn down the magnetic stirring The rotation speed of the device was increased to 200 rpm, and 4.4955 mL of titanium isopropoxide solution was quickly added to make the molar ratio of Ag and Ti in the solution 0.1 / 100. After stirring for 30 s, the solution was left to settle for 14 h. The product and solution were washed 3 times with ethanol and deionized water, dried and ground. Transfer the powder to a 100mL stainless steel high-temperature and high-pressure reactor with a polytetrafluoroethylene liner, add 40mL of ethanol and 20mL of water, place it in a muffle furnace for hydrothermal reaction at 180°C for 14h, and then cool to room temperature to obtain the product Wash with water and absolute ethanol three times respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com