Multilayer composite film and preparation method thereof, and application of multilayer composite film as connecting material for carbon fiber-reinforced carbon composite materials

A technology of multi-layer composite film and carbon composite material, which is applied in the field of composite film and carbon fiber reinforced carbon composite material, can solve the problems of unfavorable composite material mechanical properties, corrosion resistance, and non-corrosion resistance, so as to alleviate collapse failure and save energy. The effect of reducing cost and reducing production difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

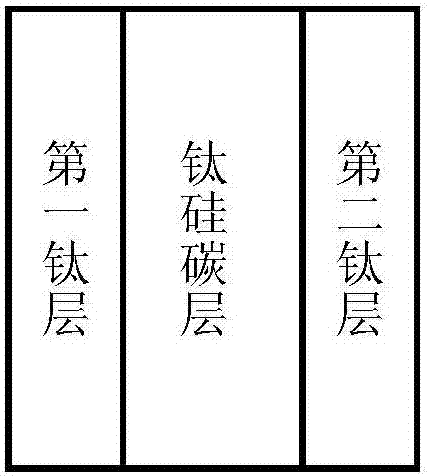

[0033] In this embodiment, the multilayer composite film structure is as figure 1 As shown, it is a composite film laminated on the left and right, and along the lamination direction on the left and right, there are the first titanium layer, the titanium silicon carbon layer and the second titanium layer in sequence. Along the left and right stacking directions, the thickness of the first titanium layer is 500 nm, the thickness of the titanium silicon carbon layer is 60 μm, and the thickness of the second titanium layer is 500 nm.

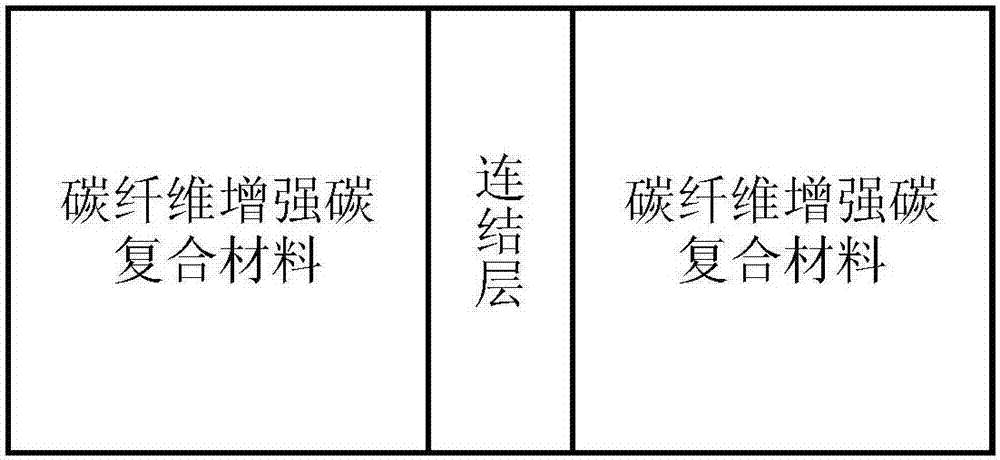

[0034] The above-mentioned multilayer composite film can be used for the connection of carbon fiber reinforced carbon composite materials. Such as figure 2 As shown, the multilayer composite film is used as the connecting material of two carbon fiber reinforced carbon composite materials to be connected. The size of the two carbon fiber reinforced carbon composite materials to be connected is 17*17*5mm. The connection method is as follows:

[00...

Embodiment 2

[0042] In this embodiment, the multilayer composite film structure is as figure 1 As shown, it is a composite film laminated on the left and right, and along the lamination direction on the left and right, there are the first titanium layer, the titanium silicon carbon layer and the second titanium layer in sequence. Along the left and right stacking directions, the thickness of the first titanium layer is 100 nm, the thickness of the titanium silicon carbon layer is 30 μm, and the thickness of the second titanium layer is 100 nm.

[0043] The above-mentioned multilayer composite film can be used for the connection of carbon fiber reinforced carbon composite materials. Such as figure 2 As shown, the multilayer composite film is used as the connecting material of two carbon fiber reinforced carbon composite materials to be connected. The size of the two carbon fiber reinforced carbon composite materials to be connected is 17*17*5mm. The connection method is as follows:

[00...

Embodiment 3

[0051] In this embodiment, the multilayer composite film structure is as figure 1 As shown, it is a composite film laminated on the left and right, and along the lamination direction on the left and right, there are the first titanium layer, the titanium silicon carbon layer and the second titanium layer in sequence. Along the left and right lamination directions, the thickness of the first titanium layer is 300 nm, the thickness of the titanium silicon carbon layer is 50 μm, and the thickness of the second titanium layer is 300 nm.

[0052] The above-mentioned multilayer composite film can be used for the connection of carbon fiber reinforced carbon composite materials. Such as figure 2 As shown, the multilayer composite film is used as the connecting material of two carbon fiber reinforced carbon composite materials to be connected. The size of the two carbon fiber reinforced carbon composite materials to be connected is 17*17*5mm. The connection method is as follows:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com