Method for preparing composite anti-wear additive through aliphatic acid grafting

A fatty acid and additive technology, applied in additives, lubricating compositions, petroleum industry, etc., can solve problems such as affecting dispersibility, and achieve the effects of extending service life, controllable synthesis, and excellent anti-wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

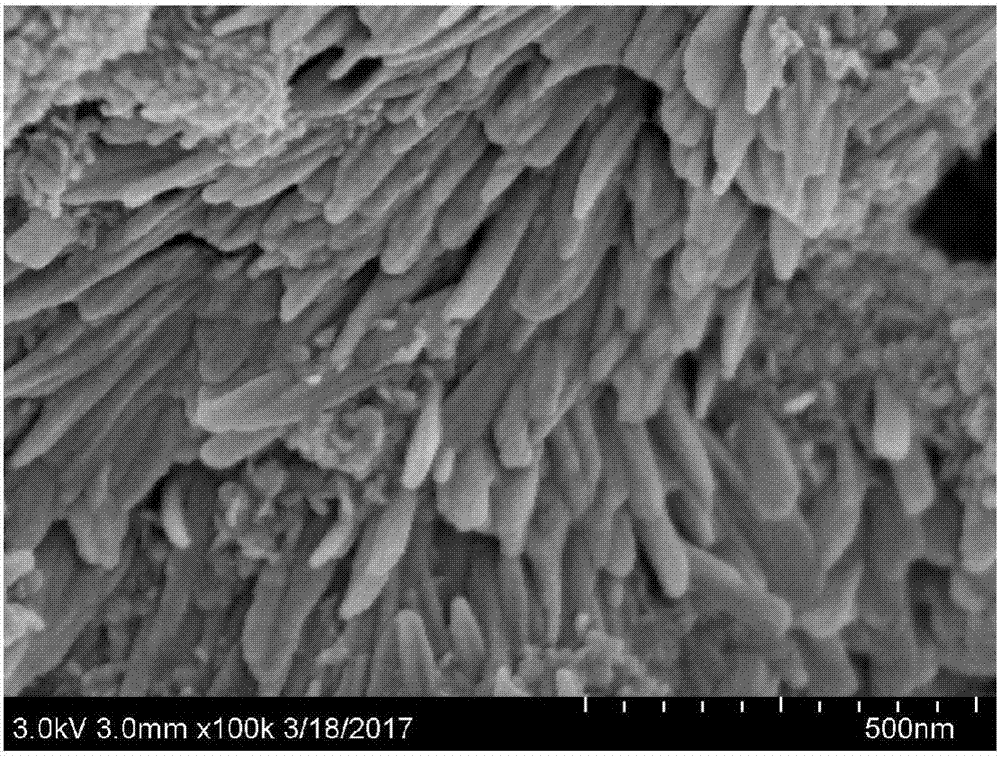

[0031] Embodiment 1: a kind of method that grafted fatty acid prepares composite anti-wear additive, comprises the following steps:

[0032] Using magnesium oxide, silicon dioxide, oleic acid as raw materials

[0033] The selected mass ratio of magnesium oxide, silicon dioxide and oleic acid is: magnesium oxide 1; silicon dioxide 1; oleic acid 0.4.

[0034] Specifically: get 4.286g of magnesium oxide (MgO) and silicon dioxide (SiO2) respectively, mix it with 14ml of sodium hydroxide solution with a concentration of 1mol / L, add 400ml of deionized water, add 1.72g (0.42wt% ) of oleic acid, the resulting mixed solution was stirred at a speed of 200r / min for 10 minutes, and the power of 60W was ultrasonicated for 10 minutes; the resulting mixed solution was transferred to a reactor, and the reactor was closed.

[0035] Set the speed of the magnetic stirrer in the reaction kettle to 450r / min, set the heating time to 90min, the holding temperature to 200°C and the holding time to 1...

Embodiment 2

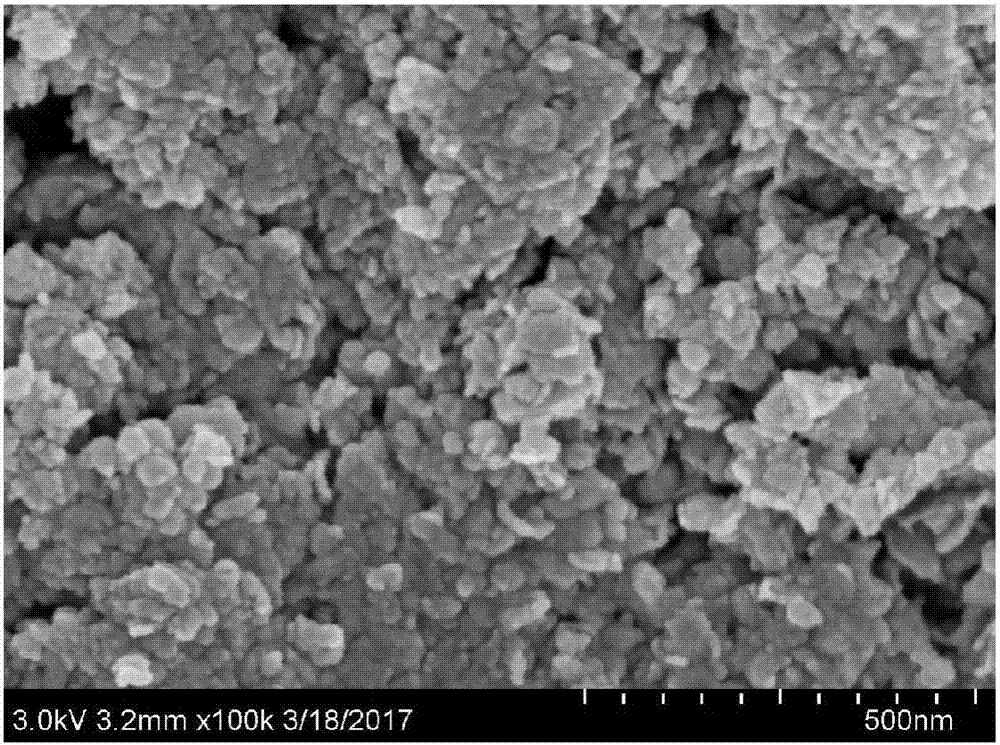

[0038] Embodiment 2: a kind of method that grafted fatty acid prepares composite anti-wear additive, comprises the following steps:

[0039] Using magnesium oxide, silicon dioxide, oleic acid as raw materials

[0040] The selected mass ratio of magnesium oxide, silicon dioxide and oleic acid is: magnesium oxide 1; silicon dioxide 1.2; oleic acid 0.6.

[0041] Specifically: take 4.286g of magnesium oxide (MgO) and 5.143g of silicon dioxide (SiO2) respectively, mix it with 15ml of sodium hydroxide solution with a concentration of 1mol / L, add 400ml of deionized water, add 2.57g (0.63 wt%) of oleic acid, the resulting mixed solution was stirred at a speed of 200r / min for 10 minutes, and the power of 60W was ultrasonicated for 10 minutes; the resulting mixed solution was transferred to a reactor, and the reactor was closed.

[0042] Set the speed of the magnetic stirrer in the reaction kettle to 450r / min, set the heating time to 90min, the holding temperature to 200°C and the hold...

Embodiment 3

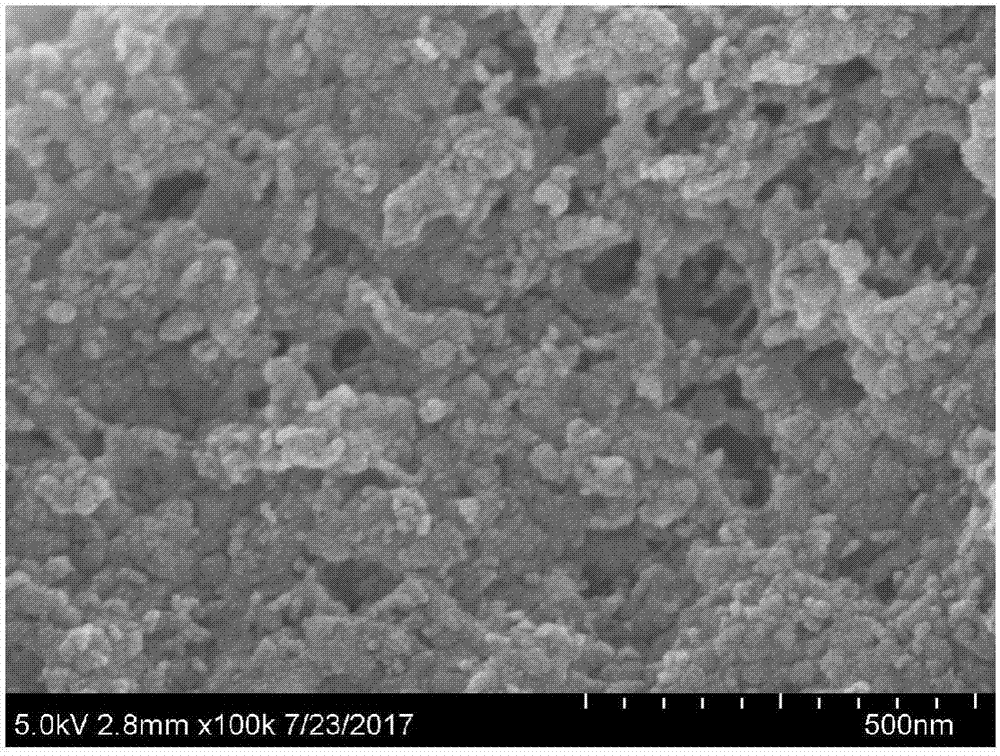

[0045] Embodiment 3: a kind of method that grafted fatty acid prepares composite anti-wear additive, comprises the following steps:

[0046] Using magnesium oxide, silicon dioxide, linoleic acid as raw materials

[0047] The selected mass ratio of magnesium oxide, silicon dioxide and linoleic acid is: magnesium oxide 1; silicon dioxide 1; linoleic acid 0.63.

[0048] Specifically: take 4.286g of magnesium oxide (MgO) and silicon dioxide (SiO2) respectively, mix it with 15ml of sodium hydroxide solution with a concentration of 1mol / L, add 400ml of deionized water, and add 2.7g of linoleic acid , the resulting mixed solution was stirred at a rotational speed of 200r / min for 10 minutes, and ultrasonicated at a power of 60W for 10 minutes; the resulting mixed solution was transferred to a reactor, and the reactor was closed.

[0049] Set the speed of the magnetic stirrer in the reaction kettle to 450r / min, set the heating time to 90min, the holding temperature to 200°C and the hold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com