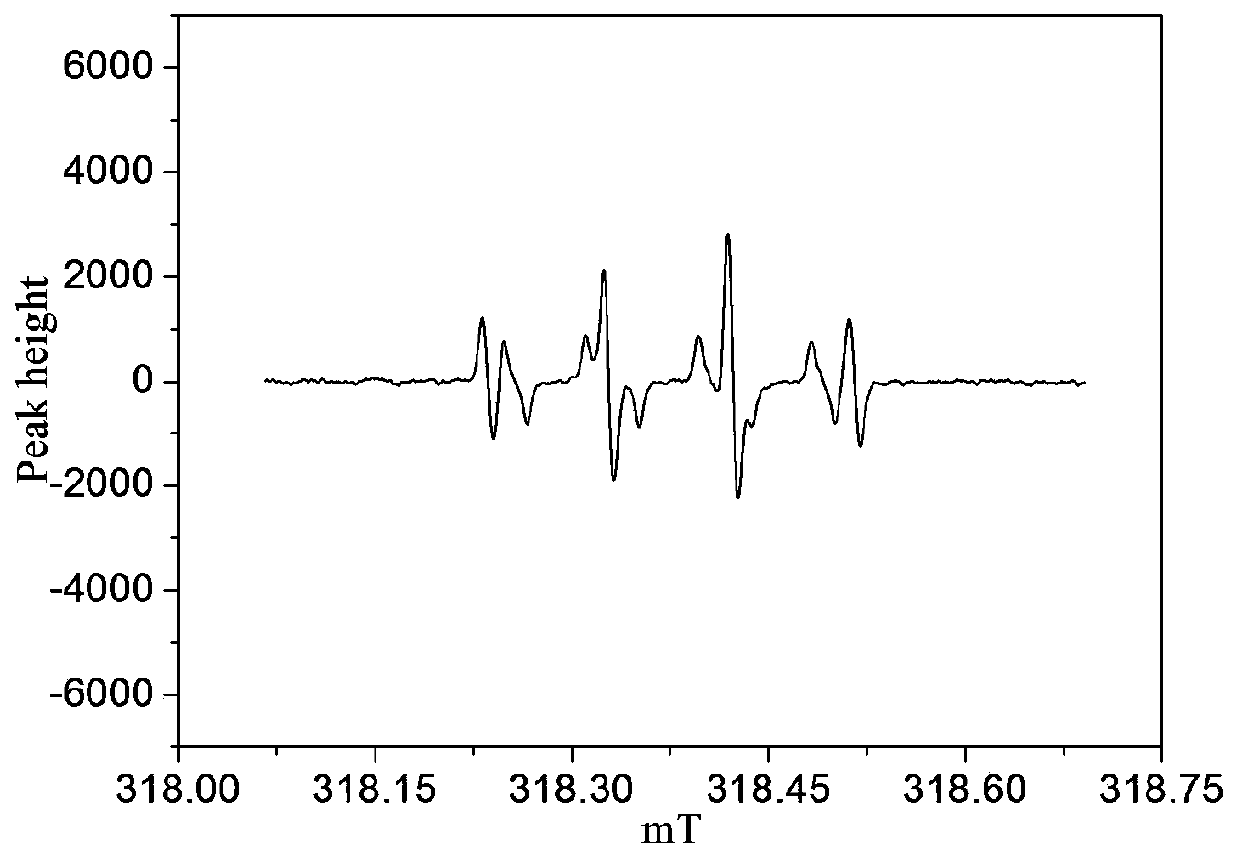

Integrated flue gas purification system and method for ozone and microwave excitation of fly ash-induced free radicals

A flue gas purification system and a technology of cooperating with microwaves, applied in the field of flue gas purification, can solve the problems of short ultraviolet light penetration distance, hinder ultraviolet light transmission, restrict the industrial application of photochemical removal system, etc., and achieve good engineering use and practical experience. , the effect of broad market development and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

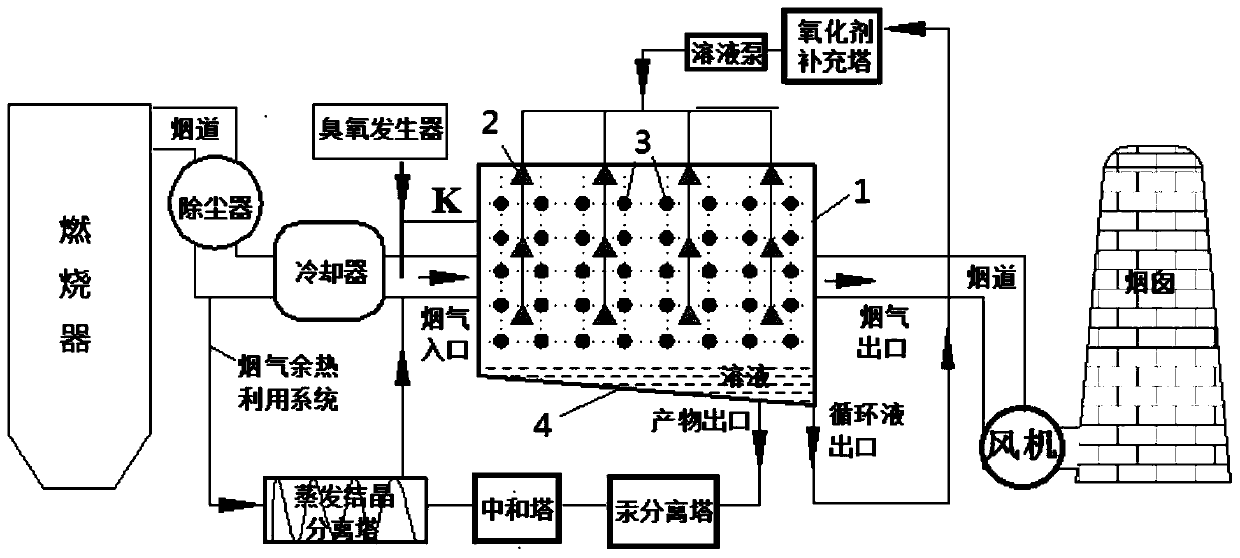

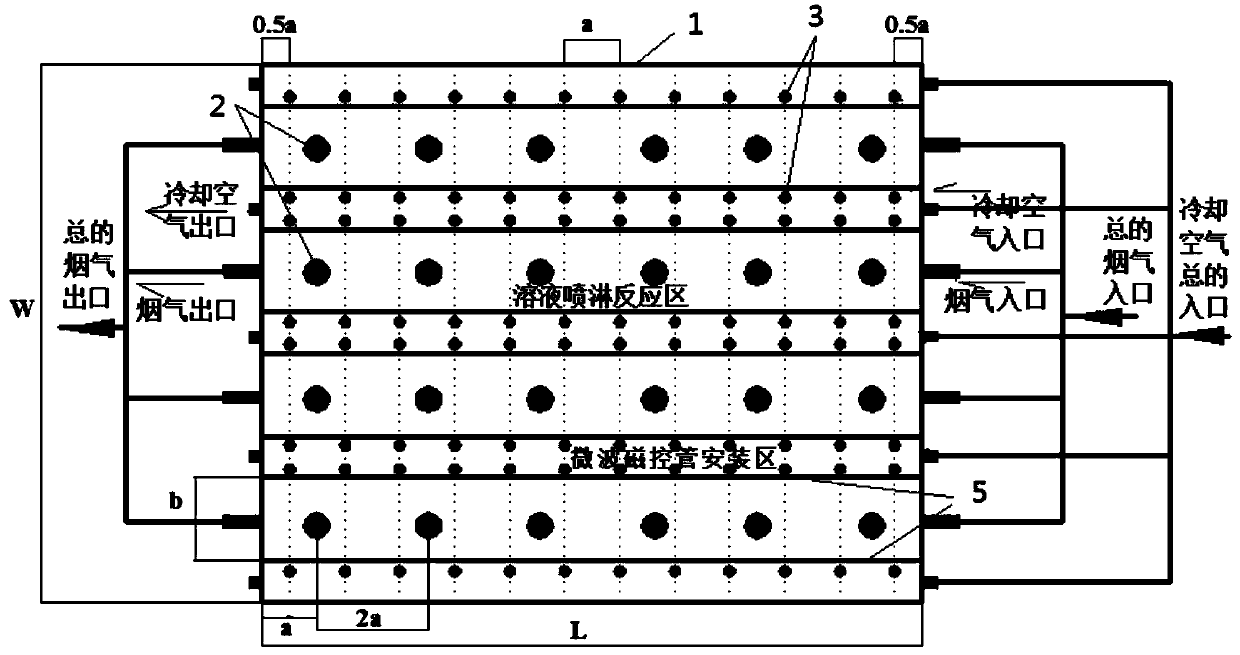

Embodiment 1

[0065] SO in flue gas 2 ﹑NO and Hg 0 Concentrations are 2000ppm, 400ppm and 60μg / m 3 , the flue gas temperature is 40°C, the ozone concentration is 100ppm, the molar concentration of ammonium persulfate is 0.2mol / L, the solution pH is 3.8, and the fly ash concentration is 5g / m 3 , the microwave radiation power density is 300W / m 3 , the liquid-gas ratio is 3L / m 3 . The results of the small test are: SO in flue gas 2 ﹑NO and Hg 0 The simultaneous removal efficiencies can reach 90.1%, 53.1% and 89.8%, respectively.

Embodiment 2

[0067] SO in flue gas 2 ﹑NO and Hg 0 Concentrations are 2000ppm, 400ppm and 60μg / m 3 , the flue gas temperature is 40°C, the ozone concentration is 100ppm, the molar concentration of ammonium persulfate is 0.6mol / L, the solution pH is 3.8, and the fly ash concentration is 5g / m 3 , the microwave radiation power density is 300W / m 3 , the liquid-gas ratio is 3L / m 3 . The results of the small test are: SO in flue gas 2 ﹑NO and Hg 0 The simultaneous removal efficiencies can reach 100%, 73.9% and 100%, respectively.

Embodiment 3

[0069] SO in flue gas 2 ﹑NO and Hg 0 Concentrations are 2000ppm, 400ppm and 60μg / m 3 , the flue gas temperature is 40°C, the ozone concentration is 200ppm, the molar concentration of ammonium persulfate is 0.6mol / L, the solution pH is 3.8, and the fly ash concentration is 5g / m 3 , the microwave radiation power density is 300W / m 3 , the liquid-gas ratio is 3L / m 3 . The results of the small test are: SO in flue gas 2 ﹑NO and Hg 0 The simultaneous removal efficiencies can reach 100%, 87.3% and 100%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com