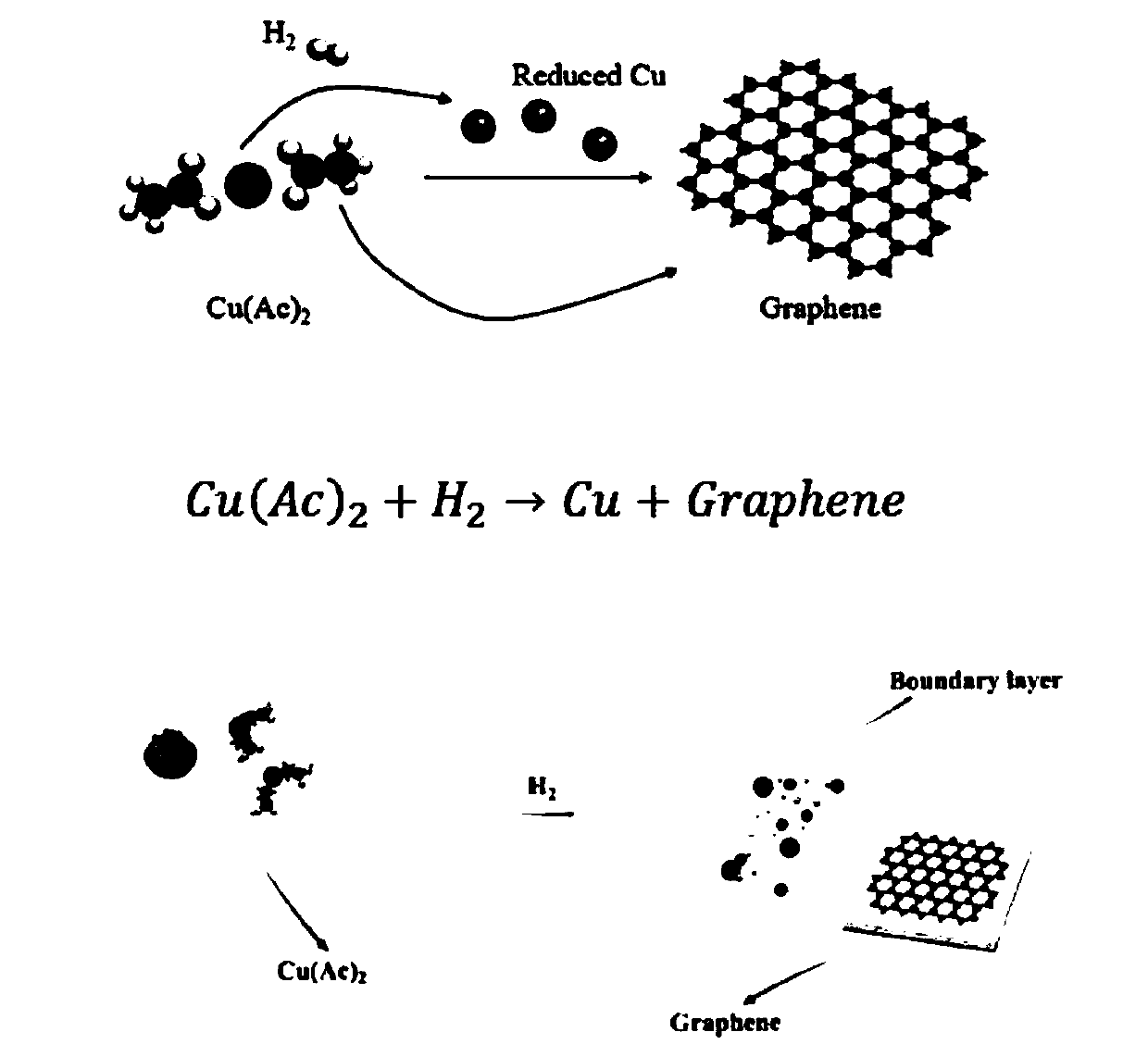

A kind of method utilizing copper acetate to prepare ultra-clean graphene

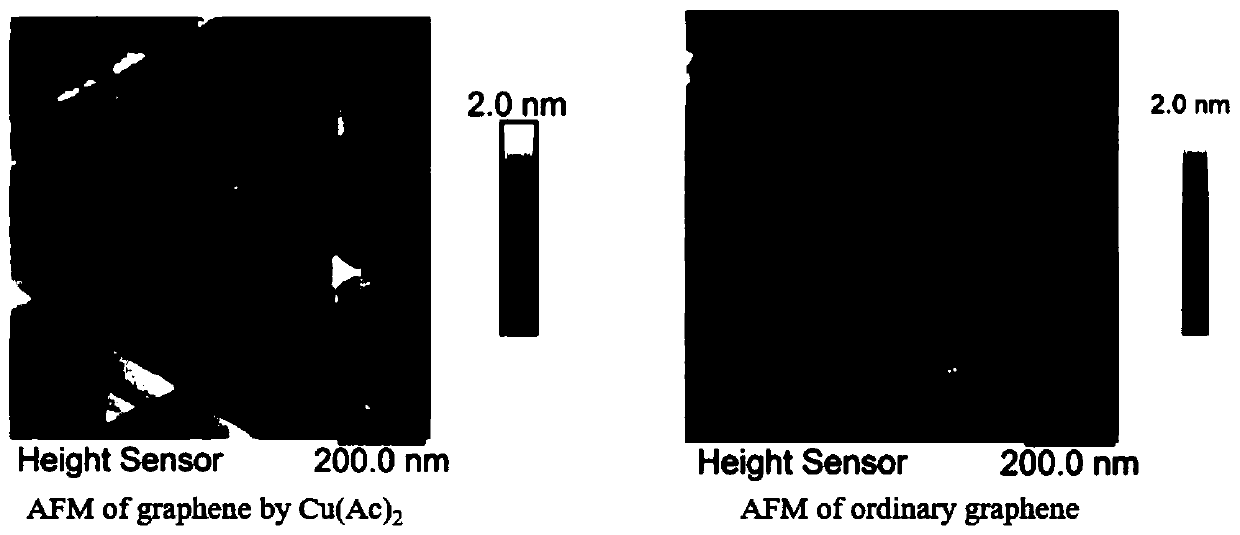

A copper acetate and graphene technology, applied in the field of materials, can solve the problems of affecting the mechanical properties and thermal conductivity of graphene, affecting the electrical transport properties and light transmittance of graphene, etc., and achieves a simple and effective preparation method, clean surface, The effect of promoting catalytic cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, preparation ultra-clean graphene

[0042] (1) Using phosphoric acid and ethylene glycol solution with a mass ratio of 3:1 as the electrolyte, copper foil (produced by Alfa Aesar, with a purity of 99.8%, and a thickness of 25 μm) was connected to the positive electrode, and polished at a DC current of 0.8 A for 15 minutes. Place the copper foil in a casing with a magnetic control device, then place the casing in a tube furnace, place copper acetate solid powder in a quartz boat and place it upstream of the copper foil, under a hydrogen atmosphere with a flow rate of 100 sccm , raise the temperature of the furnace body to 1020°C and keep it for 60 minutes;

[0043] (2) Keep the temperature of the furnace body at 1020°C, feed in hydrogen gas with a flow rate of 100sccm, heat the copper acetate powder to 220°C to volatilize it, the heating rate is 40°C / min, keep it for 5 minutes, that is, carry out chemical vapor deposition for 5 minutes ;

[0044] (3) Use a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com