A kind of monodisperse yolk-shell structure silicon dioxide microsphere preparation method

A silicon dioxide, monodisperse technology, applied in the direction of silicon dioxide, silicon oxide, nanotechnology for materials and surface science, etc., can solve the problems of simple reaction conditions, less green and environmental protection processes, etc., to achieve simple preparation process, The effect of uniform shape and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

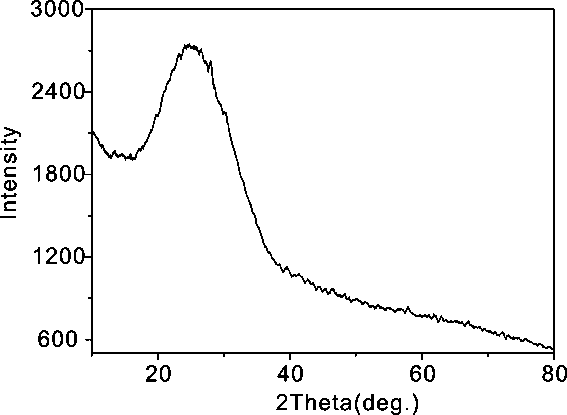

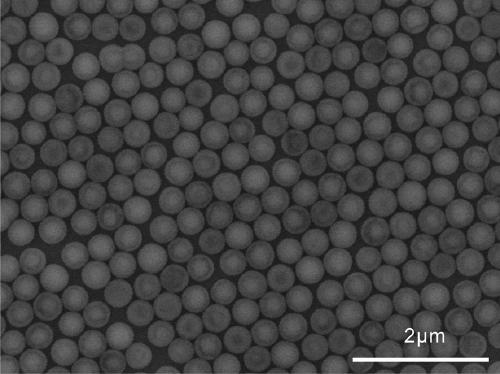

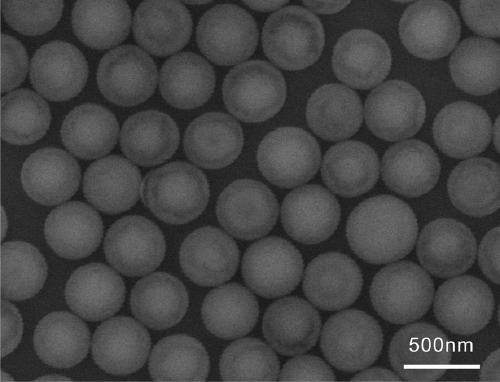

Image

Examples

Embodiment 1

[0028] (1) Weigh 0.1g of sodium metaaluminate (NaAlO 2 ), put it into a clean beaker, add 30mL of deionized water and fully magnetically stir to form a colorless and transparent solution A;

[0029] (2) Weigh 0.11g of silica microspheres with a diameter of about 400nm, put them into a clean beaker, add 20mL of deionized water, and then fully ultrasonically and magnetically stir to form a white emulsion B;

[0030] (3) Under the joint action of ultrasonic and magnetic stirring, after pouring the solution A obtained in step (1) into the white emulsion B obtained in step (2), continue the joint action of ultrasonic and magnetic stirring for 10 minutes to prepare a mixed white emulsion C;

[0031] (4) Transfer the mixed white emulsion C obtained in step (3) to a reaction kettle with a polytetrafluoroethylene liner, seal it completely, heat it at a constant temperature of 140°C for 30 minutes, take out the liner, and pour off the upper layer Add water to the waste liquid, transfe...

Embodiment 2

[0039] (1) Weigh 0.08g sodium metaaluminate (NaAlO 2 ), put it into a clean beaker, add 30mL of deionized water and fully magnetically stir to form a colorless and transparent solution A;

[0040] (2) Weigh 0.10 g of silica microspheres (about 400 nm in diameter), put them into a clean beaker, add 20 mL of deionized water, and then fully ultrasonically and magnetically stir to form a white emulsion B;

[0041] (3) Under the combined action of ultrasonic and magnetic stirring, after pouring the solution A obtained in step (1) into the white emulsion B obtained in step (2), continue the combined action of ultrasonic and magnetic stirring for a certain period of time to prepare a mixed white emulsion C;

[0042](4) Transfer the mixed white emulsion C obtained in step (3) to a reaction kettle with a polytetrafluoroethylene liner, seal it completely, heat it at a constant temperature of 140°C for 30 minutes, take out the liner, and pour off the upper layer Add water to the waste ...

Embodiment 3

[0045] (1) Weigh 0.08g sodium metaaluminate (NaAlO 2 ), put it into a clean beaker, add 30mL of deionized water and fully magnetically stir to form a colorless and transparent solution A;

[0046] (2) Weigh 0.10 g of silica microspheres (about 400 nm in diameter), put them into a clean beaker, add 20 mL of deionized water, and then fully ultrasonically and magnetically stir to form a white emulsion B;

[0047] (3) Under the combined action of ultrasonic and magnetic stirring, after pouring the solution A obtained in step (1) into the white emulsion B obtained in step (2), continue the combined action of ultrasonic and magnetic stirring for a certain period of time to prepare a mixed white emulsion C;

[0048] (4) Transfer the mixed white emulsion C obtained in step (3) to a reaction kettle with a polytetrafluoroethylene liner, seal it completely, heat it at a constant temperature of 160°C for 30 minutes, take out the liner, and pour off the upper layer Add water to the waste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com