Purifying method for rabeprazole

A technology of rabeprazole and its refining method, which is applied in the field of medicinal chemistry, can solve the problems of loss of raw material drug rabeprazole sodium, huge additional costs, and solvents that cannot be used mechanically, and achieve solvent recovery and mechanical application, high product recovery rate, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

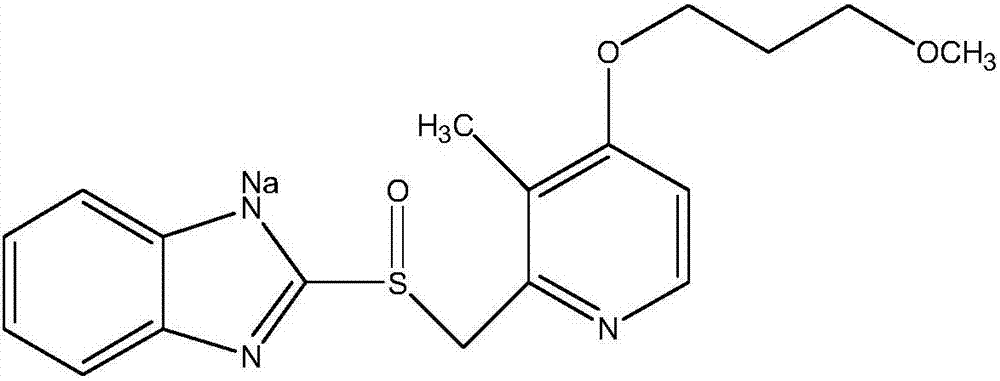

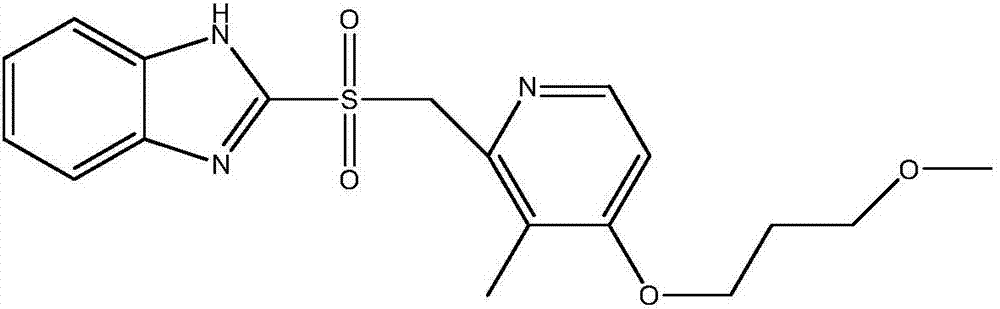

Image

Examples

Embodiment 1

[0022] 40g purity is 99.5% rabeprazole crude product (peroxide impurity content is 0.3%) drop in the flask that contains 200ml dichloromethane, add 0.8g silica gel in flask, at 5~10 ℃, stirring adsorption 2 Hour. Filtrate with suction, concentrate the filtrate to dryness, recover the solvent and place it, and apply it to the next batch. Add 100ml of isopropyl ether to the concentrated solution, raise the temperature to 35°C, stir for 30 minutes, then lower the temperature to 5°C and stir for 2 hours, filter with suction, and wash the filter cake with an appropriate amount of isopropyl ether. After drying, 37 g of refined rabeprazole was obtained, with a yield of 92.5%, an HPLC purity of 99.92%, and a peroxide impurity content of 0.04%.

Embodiment 2

[0024] The rabeprazole crude product (peroxide impurity content is 0.2%) that 40g purity is 99.7% is dropped in the flask that contains 150ml methanol, adds 2g gac in the flask, stirs and adsorbs at room temperature for 2 hours. Suction filtration, the filtrate was concentrated to dryness, the solvent was recovered and placed, and used for the next batch. Add 120ml of acetonitrile to the concentrated solution, raise the temperature to 35°C, stir to dissolve, then cool down to 5°C and stir for 2 hours, filter with suction, and wash the filter cake with an appropriate amount of acetonitrile. After drying, 36.5 g of fine rabeprazole was obtained, with a yield of 91.25%, an HPLC purity of 99.91%, and a peroxide impurity content of 0.04%.

Embodiment 3

[0026] 40g purity is 99.6% rabeprazole crude product (peroxide impurity content is 0.35%) drop in the flask that contains 160ml ethyl acetate, add 1g neutral alumina in flask, stir and adsorb at room temperature for 2 hours . Suction filtration, the filtrate was concentrated to dryness, the solvent was recovered and placed, and used for the next batch. Add 200ml of methyl tert-butyl ether to the concentrated solution, raise the temperature to 35°C, stir for 10 minutes, then lower the temperature to 15°C and stir for 2 hours, filter with suction, and wash the filter cake with an appropriate amount of methyl tert-butyl ether. After drying, 38 g of fine rabeprazole was obtained, with a yield of 95%, an HPLC purity of 99.95%, and a peroxide impurity content of 0.03%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com