Anticorrosive coating for low surface treatment stainless steel substrate and preparation method of anticorrosive coating

A low surface treatment, anti-corrosion coating technology, used in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problem of acid and alkali resistance of alkyd system, poor salt water resistance, increase process flow and process cost, stainless steel base It is difficult to adhere to the coating and other problems, so as to avoid weak corrosion resistance, excellent wetting ability, and excellent rust prevention ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

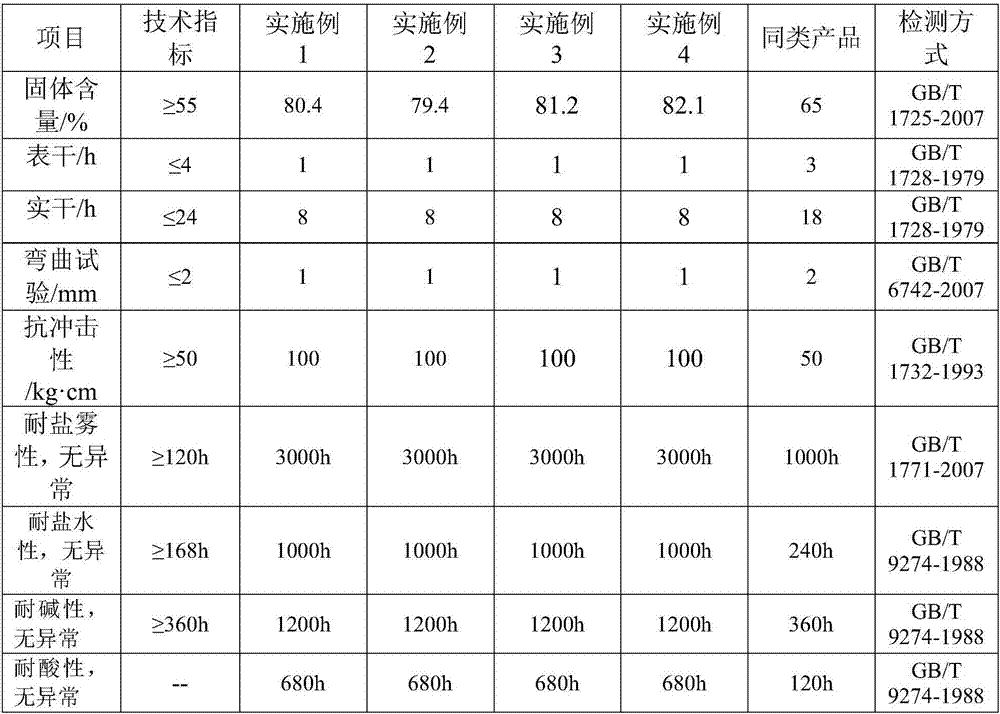

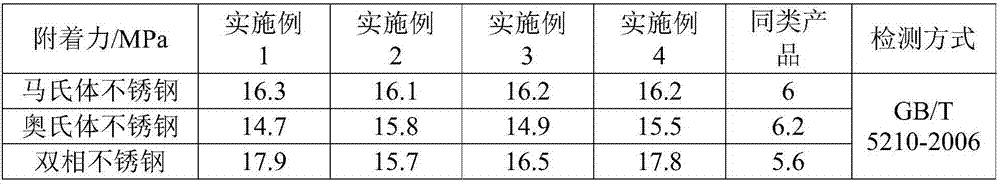

Examples

Embodiment 1

[0040] The anticorrosion coating for stainless steel substrates with low surface treatment in this embodiment includes: component A and component B, and the weight ratio of component A to component B is 100:20.

[0041] 1) Component A includes the following substances by weight ratio:

[0042] Low epoxy value epoxy resin 28%, Nanya NPES 907, its epoxy equivalent is 1500-1800g / eq;

[0043] γ-Aminopropyltrialkoxysilane 4%;

[0044] High epoxy value epoxy resin 6%, Nanya NPEL 127, its epoxy equivalent is 176-184g / eq;

[0045] Aluminum tripolyphosphate 25%;

[0046] Complex zinc phosphate 16%;

[0047] Precipitated barium sulfate 8.8%, passed through 700 mesh sieve;

[0048] Organic soil slurry 2%;

[0049] Polyacrylate 0.2%, Cam KM-115;

[0050] The first solvent is 10%, wherein, xylene:n-butanol:methyl isobutyl ketone=45:35:20.

[0051] 2) Component B includes the following substances by weight percentage:

[0052] Polyamide resin 75%;

[0053] Carboxy-terminated nitril...

Embodiment 2

[0062] The anticorrosion coating for stainless steel substrates with low surface treatment in this embodiment includes: component A and component B, and the weight ratio of component A to component B is 100:25.

[0063] 1) Component A includes the following substances by weight ratio:

[0064] Low epoxy value epoxy resin 25%, is Mitsui R307, its epoxy equivalent is 1750-2100g / eq;

[0065] γ-Aminopropyltrialkoxysilane 5%;

[0066] High epoxy value epoxy resin 8%, Mitsui R139, its epoxy equivalent is 180-190g / eq;

[0067] Aluminum tripolyphosphate 20%;

[0068] Composite zinc phosphate 20%;

[0069] Precipitated barium sulfate 7.8%, passed through 800 mesh sieve;

[0070] Organic soil slurry 2%;

[0071] Polyacrylate 0.2%, Junjiang D 0190;

[0072] The first solvent 12%, wherein, xylene: n-butanol: methyl isobutyl ketone=50:30:20;

[0073] 2) Component B includes the following substances by weight percentage:

[0074] Polyamide resin 80%;

[0075] Carboxyl-terminated ni...

Embodiment 3

[0084] The anticorrosion coating for stainless steel substrates with low surface treatment in this embodiment includes: component A and component B, and the weight ratio of component A to component B is 100:15.

[0085] 1) Component A includes the following substances by weight ratio:

[0086] Low epoxy value epoxy resin 15%, Nanya NPES 907, epoxy equivalent 1500-1800g / eq;

[0087] γ-Aminopropyltrialkoxysilane 2%;

[0088] High epoxy value epoxy resin 5%, is Mitsui R139, its epoxy equivalent is 180-190g / eq;

[0089] Aluminum tripolyphosphate 29%;

[0090] Composite zinc phosphate 25%;

[0091] Precipitated barium sulfate 8%, passed through 800 mesh sieve;

[0092] Organic soil slurry 1.5%;

[0093] Polyacrylate 0.3%, Huntsman 125-3;

[0094] The first solvent is 14.2%, wherein, xylene: n-butanol: methyl isobutyl ketone=55:25:20;

[0095] 2) Component B includes the following substances by weight percentage:

[0096] Polyamide resin 70%;

[0097] Carboxy-terminated nit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com