Laminated strip-shaped self-brazing filler metal for aluminum-copper brazing and preparation method thereof

A strip-shaped and brazing technology, which is applied in the direction of welding equipment, welding/cutting media/materials, welding media, etc., can solve the problem of restricting the promotion and application of copper-aluminum joints, poor stability of core filling coefficient, and difficulty in removing film and flow aid and other problems, to achieve high flux stability and wetting ability, joint toughness, and reduce the effect of brittle phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

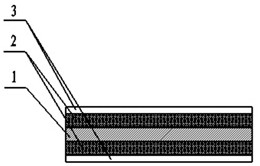

[0036]A laminated ribbon self-soldering solder for copper-aluminum brazing, seefigure 1 The self-soldering solder has a five-layer laminated ribbon structure, the innermost layer is a pure nickel layer 1, the outer sides of the pure nickel layer 1 are solder layers 2, and the outer sides of the solder layer 2 are flux layers 3. The brazing material layer is made of raw materials with the following weight percentages: Al is 1.5%, and Zn is 98.5%. The thickness of the solder layer and the pure nickel layer are the same, and the thickness of the solder layer is 1 / 3 of the thickness of the solder layer or the pure nickel layer. The total thickness of the laminated ribbon-shaped self-soldering solder is 0.1 mm.

[0037]The method for preparing the laminated ribbon-shaped self-soldering solder for copper-aluminum brazing includes the following steps:

[0038]Step 1. Weigh Zn and Al raw materials in a graphite crucible and heat them to 550°C in a graphite crucible and melt them into molten metal...

Embodiment 2

[0045]A laminated ribbon self-soldering solder for copper-aluminum brazing, seefigure 1 The self-soldering solder has a five-layer laminated ribbon structure, the innermost layer is a pure nickel layer 1, two outsides of the pure nickel layer 1 are solder layers 2, and both outsides of the solder layer 2 are flux layers 3. The brazing material layer is made of the following raw materials in weight percentages: Al is 2%, and Zn is 98%. The thickness of the solder layer and the pure nickel layer are consistent, and the thickness of the solder layer is 1 / 2 of the thickness of the solder layer or the pure nickel layer. The total thickness of the laminated ribbon-shaped self-soldering solder is 0.2 mm.

[0046]The method for preparing the above-mentioned laminated ribbon self-soldering solder for copper-aluminum brazing includes the following steps:

[0047]Step 1. Weigh Zn and Al raw materials in a graphite crucible and heat them to 560°C in a graphite crucible, and melt them into molten meta...

Embodiment 3

[0054]A laminated ribbon self-soldering solder for copper-aluminum brazing, seefigure 1 The self-soldering solder has a five-layer laminated ribbon structure, the innermost layer is a pure nickel layer 1, the outer sides of the pure nickel layer 1 are solder layers 2, and the outer sides of the solder layer 2 are flux layers 3. The brazing material layer is made of the following raw materials by weight percentage: Al is 5% and Zn is 95%. The thickness of the solder layer and the pure nickel layer are consistent, and the thickness of the solder layer is 1 / 3 of the thickness of the solder layer or the pure nickel layer. The total thickness of the laminated ribbon-shaped self-soldering solder is 0.4 mm.

[0055]The method for preparing the above-mentioned laminated ribbon self-soldering solder for copper-aluminum brazing includes the following steps:

[0056]Step 1. Weigh Zn and Al raw materials according to weight percentage, heat them to 580°C in a graphite crucible, and melt them into mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com