Prefabricated type pipe rack

A prefabricated, pipe gallery technology, applied in the direction of pipes, rigid pipes, pipe protection, etc., can solve the problems of low production and processing efficiency, limited raw material sources, complex pipe structure, etc., to achieve convenient processing, simple structure, high mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

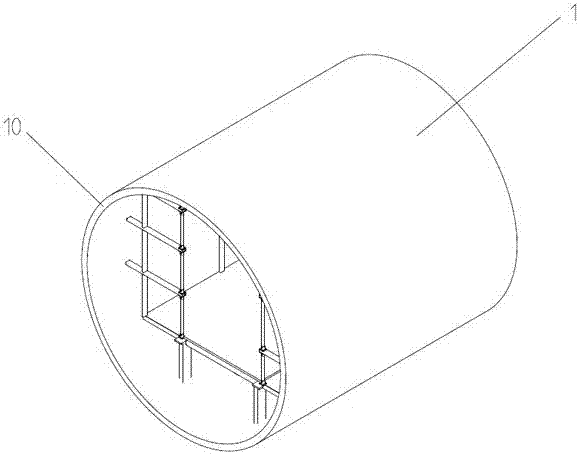

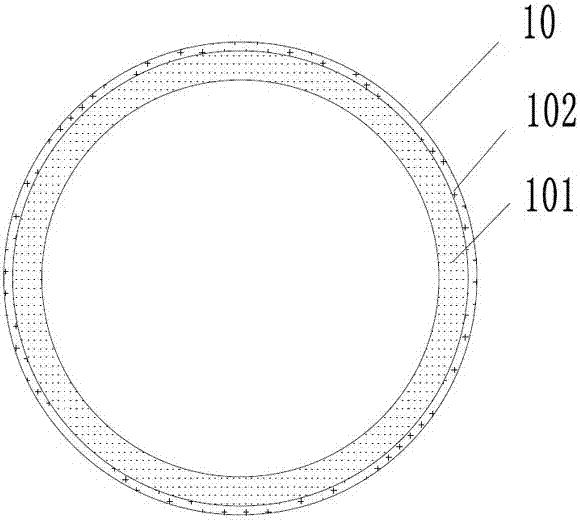

[0033] A prefabricated pipe gallery. The pipe gallery is formed by connecting several pipe joints prefabricated in the factory on site. The pipe body of the pipe joint has a structural layer and an outer protective layer in the radial direction from the inside to the outside. The above structural layer is formed by winding multiple layers of wood and bonding and curing through flame-retardant epoxy resin. For planing wood such as veneer and laminated veneer lumber, the outer protective layer is made of epoxy resin. Its concrete preparation steps are as follows:

[0034] (1) Mandrel treatment: make mandrels with the cross-sectional shape and size required for the pipe gallery, and apply a release agent on the surface of the mandrels;

[0035] (2) Structural layer forming: After the planed veneer or laminated veneer is impregnated with flame retardant epoxy resin, it is spirally wound on the surface of the mandrel with a certain tension and angle, wound to the thickness of the ...

Embodiment 2

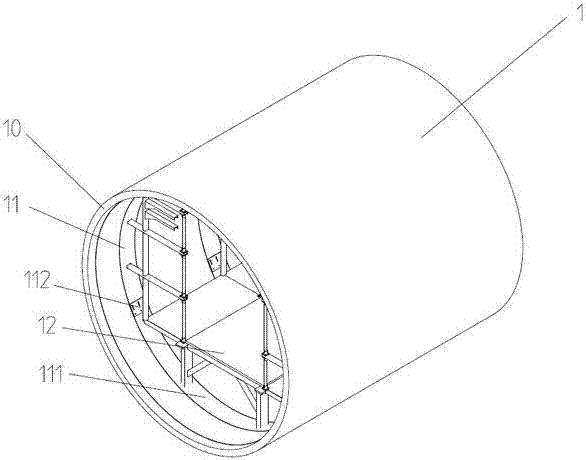

[0041] A prefabricated pipe gallery. The pipe gallery is formed by connecting several pipe joints prefabricated in the factory on site. The pipe body of the pipe joint has a structural layer and an outer protective layer in the radial direction from the inside to the outside. The structure layer is formed by winding the stalks of hemp plants in multiple layers and bonding and solidifying them through flame-retardant phenolic resin. The protective layer is made of polyurethane resin, and the inner surface of the tube is bonded with connecting components. Its concrete preparation steps are as follows:

[0042] (1) Mandrel treatment: make mandrels with the cross-sectional shape and size required for the pipe gallery, set a rubber ring at one end of the mandrel, and then apply a release agent on the outer surface of the mandrel covered with rubber rings;

[0043] (2) Structural layer forming: After drying the high-strength and high-toughness hemp skin stripped from the hemp stem,...

Embodiment 3

[0049] A prefabricated pipe gallery. The pipe gallery is formed by connecting several pipe joints prefabricated in the factory on site. The pipe body of the pipe joint has a structural layer and an outer protective layer in the radial direction from the inside to the outside. The structural layer is formed by winding multiple layers of straw and bonding and curing through flame-retardant polyurethane resin. The straw can be specifically selected from rice straw, wheat straw, sorghum stalk, corn stalk, etc. As a result, the inner surface of the tube is riveted with connecting members. Its concrete preparation steps are as follows:

[0050] (1) Mandrel treatment: make mandrels with the cross-sectional shape and size required for the pipe gallery, set a rubber ring at one end of the mandrel, and then apply a release agent on the outer surface of the mandrel covered with rubber rings;

[0051] (2) Structural layer forming: dry straw, wheat straw, sorghum stalk, corn stalk and oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com