Preparation method of fuel cell anode catalyst

A fuel cell and catalyst technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as increased process complexity and material costs, decreased carrier interface adsorption stability, and decreased battery life, achieving good synergistic effects and improving Electrocatalytic performance and the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

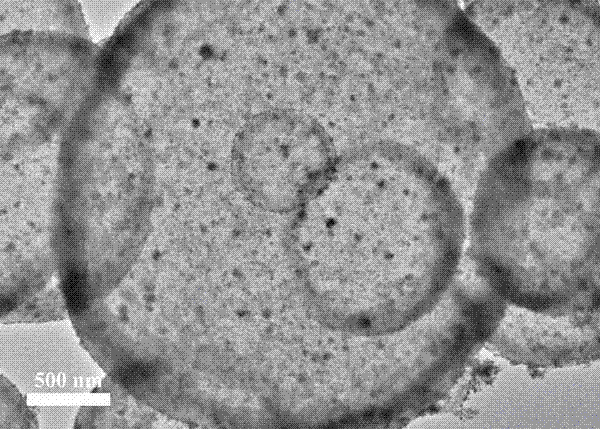

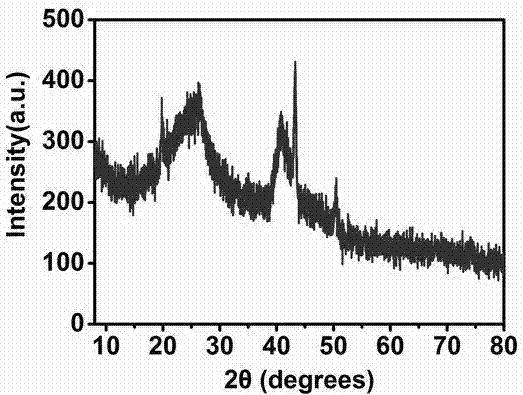

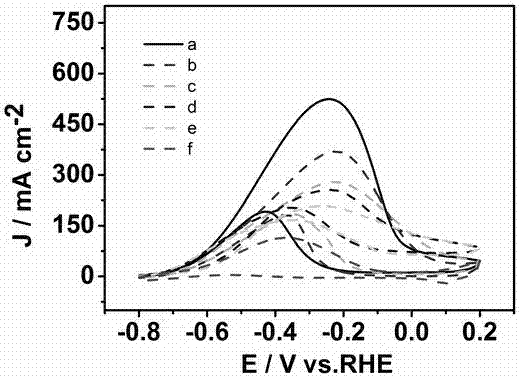

Embodiment 1

[0021] 0.01g of melamine and 0.01g of pyrophosphoric acid and 40mL of deionized water were dispersed and mixed uniformly by ultrasonic to form a solution, then 0.1g of ferric chloride was added and stirred and mixed uniformly to obtain a suspension; the obtained suspension was transferred to a high-pressure reactor sealed in a medium, reacted at 150°C for 6h, and cooled naturally to room temperature after the reaction; washed the obtained product with deionized water until the filtrate became colorless, put it in a vacuum drying oven at 80°C and dried to constant weight, and then 2 Calcined at 800°C for 4 hours under the atmosphere to obtain phosphorus, nitrogen, and iron co-doped carbon material; disperse 40 mg of the obtained phosphorus, nitrogen, and iron co-doped carbon material in 20 mL of ethylene glycol, and ultrasonically stir for 2 hours to obtain a dispersion; Add 2.5mL 20mM PdCl to the dispersion 2 aqueous solution and 20 mg CuSO 4 ·5H 2 O, stir until mixed evenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com