Preparation method and application of PdSn-CuO composite material with nano-porous structure

A nano-porous and composite material technology, applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems of low catalytic performance and poor anti-poisoning ability of methanol fuel cell anode catalysts, so as to improve anti-poisoning ability and catalytic performance, High specific surface area, simple and easy-to-control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: with Al 84 PD 5 sn 10 Cu 1 Preparation of PdSn-CuO composite material with nanoporous structure from amorphous alloy strips, the steps are as follows:

[0028] Step 1. Prepare Al with a thickness of about 20um according to the content of 10 atomic percent of Sn, 5 atomic percent of Pd, 84 atomic percent of Al, and 1 atomic percent of Cu. 84 PD 5 sn 10 Cu 1 Amorphous alloy strips.

[0029] Step two, the composition is Al 84 PD 5 sn 10 Cu 1 The amorphous alloy strips are cut into amorphous alloy splines with a width of 20 mm and a length of 2 cm.

[0030] Step 3, remove 0.1g and 40ml of aqueous sodium hydroxide solution with a molar concentration of 3 moles from the amorphous alloy sample strip obtained in step 2, and place them together in a closed container, and put them in a drying oven with a reaction temperature of 60°C, and keep them warm 48h.

[0031] Step 4: Wash the sample after the reaction in Step 3 repeatedly with deionized water and...

Embodiment 2

[0037] Embodiment 2: with Al 84 PD 5 sn 10 Cu 2 The preparation of nanoporous PdSn-CuO composite material from amorphous alloy strips is the same as step two and four in embodiment 1, except that the atomic percentage of Cu and the concentration of corrosive liquid sodium hydroxide aqueous solution in step one and step three different, namely:

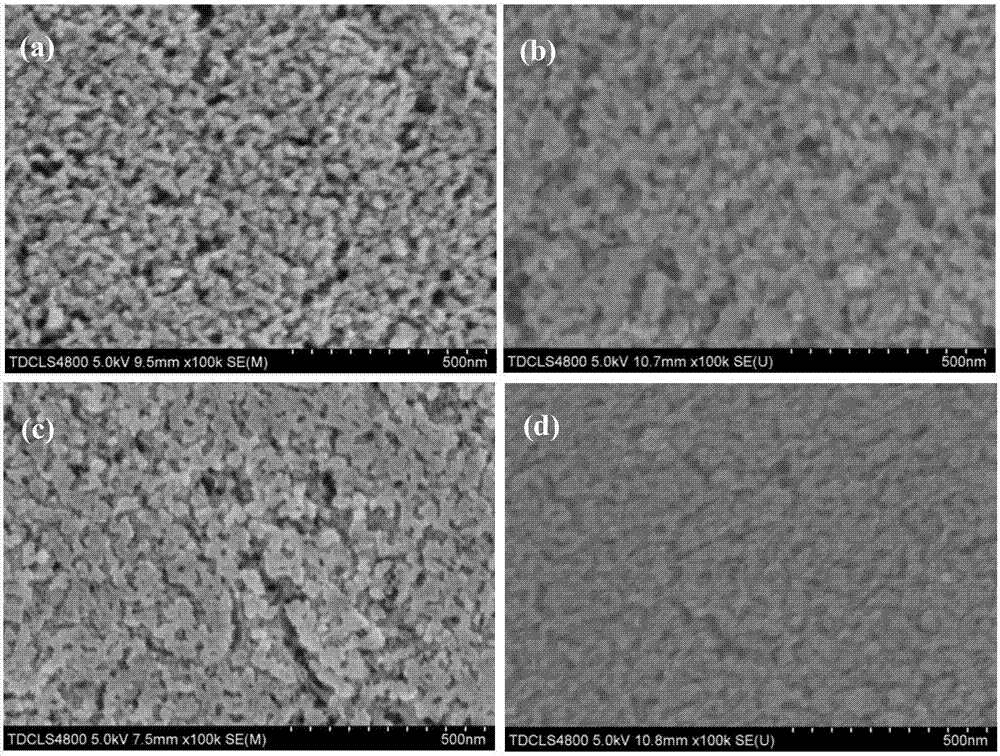

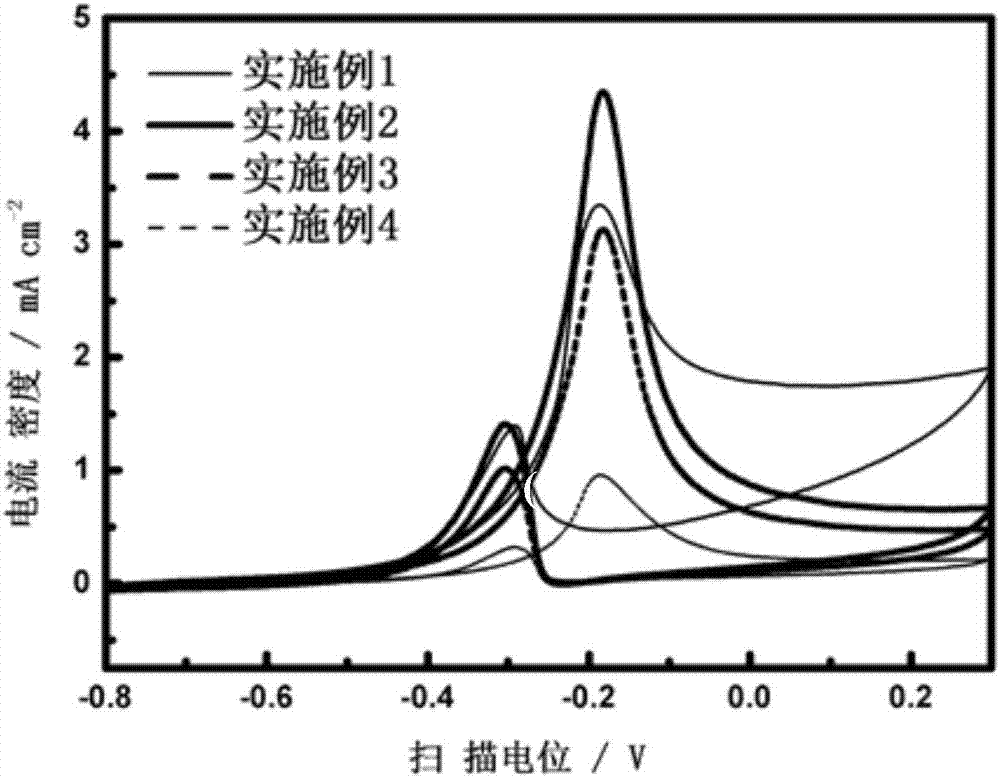

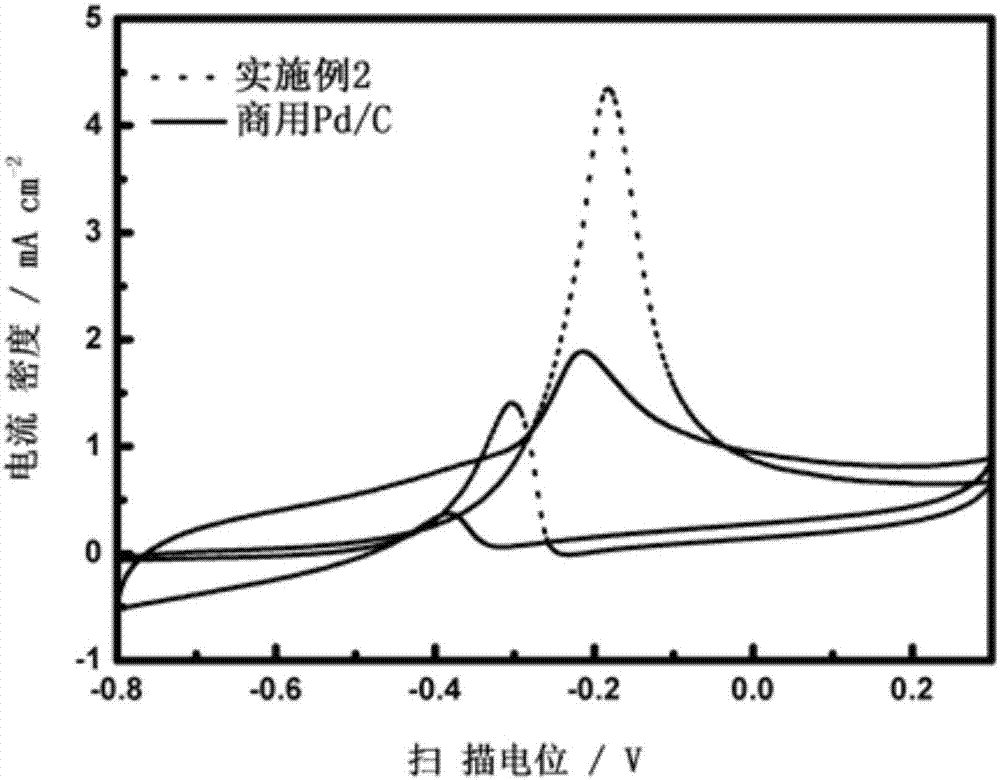

[0038] The atomic percentage of Cu in step 1 is 2%, the concentration of sodium hydroxide solution in step 3 is 1 mole, the reaction temperature is 60°C, and the reaction time is 48h. figure 1 (b) shows the SEM image of the PdSn-CuO composite nanoporous structure material prepared in Example 2, the pore diameter is 20nm, and the ligament width is 36nm. The PdSn-CuO composite material prepared in this example was applied in the performance test of electrocatalyzing methanol under alkaline conditions. figure 2 The middle thick solid line shows the cyclic voltammetry curve of the nanoporous structure of the PdSn-CuO composite materi...

Embodiment 3

[0039] Embodiment 3: with Al 83 PD 5 sn 10 Cu 2 The preparation of nanoporous PdSn-CuO composite material from amorphous alloy strips is the same as step 2 and step 4 in embodiment 1, except that the atomic percentage of Cu in step 1 and the concentration of sodium hydroxide corrosion solution in step 3, the reaction The temperature and time are different, namely:

[0040] The atomic percentage content of Cu in step 1 is 2%, the concentration of sodium hydroxide aqueous solution in step 3 is 1 mole, the reaction temperature is 50°C, and the reaction time is 36h. figure 1 (c) shows the microscopic photo of the Pd-Sn composite material with nanoporous structure prepared in Example 3, the pore diameter is 24nm, and the ligament width is 31nm. The PdSn-CuO composite material prepared in this example was applied in the performance test of electrocatalyzing methanol under alkaline conditions. figure 2 The thick dotted line in shows the cyclic voltammetry curve of the nanoporou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com