Production method and device for butanol by fermentation coupled separation and purification

A technology for purifying butanol and butanol, applied in the biological field, can solve the problems of low separation efficiency and low concentration of separated products, and achieve the effects of solving membrane pollution, saving purification energy consumption, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0063] The present invention will be specifically described below in conjunction with the examples by taking the acetone-butanol-producing bacteria as an example. However, the present invention is not limited to the following examples, and the present invention can be appropriately modified within the range consistent with the purpose of the present invention. In addition, in the following examples, unless otherwise specified, the experimental methods used are conventional methods, and the materials and reagents used can be purchased from biological or chemical companies.

[0064] Acetobutanol-producing bacteria: Clostridium acetobutylicum (Clostridium acetobutylicum), purchased from the American ATCC strain bank (ATCC number: 55025-E604).

[0065] The pretreatment method of corn stalks: crush the corn stalks, pass through a 0.4mm sieve, add 200g of crushed and sieved corn stalks to 2L of 2% (w / v) NaOH solution, react at 120°C for 30min, cool to room temperature, Filter, wash...

Embodiment 1

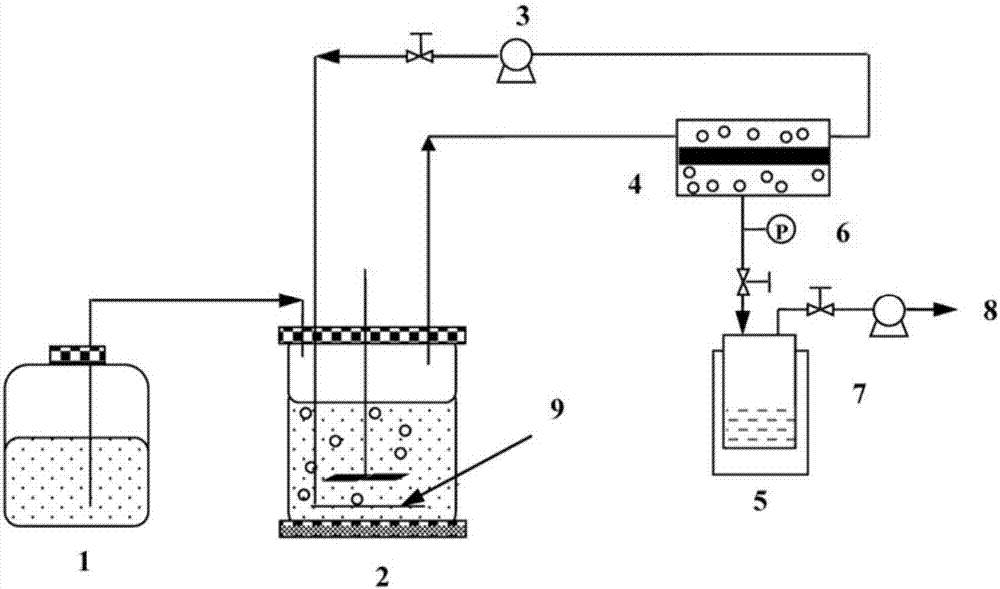

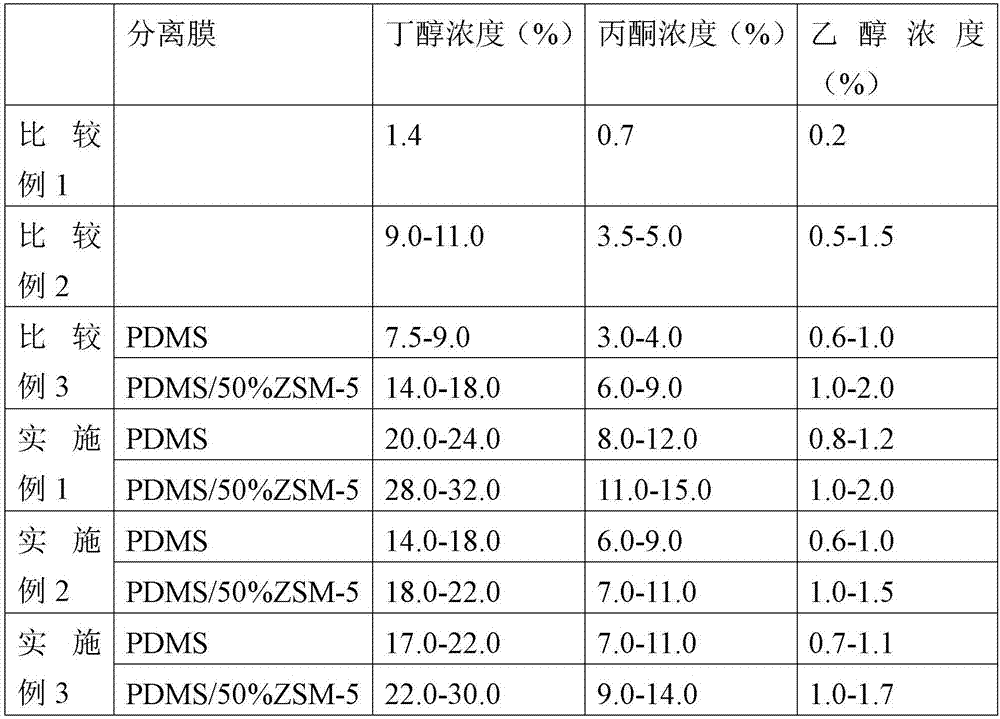

[0082] Example 1 Production of butanol, acetone and ethanol by gasification-osmotic coupled fermentation with glucose as carbon source

[0083] The cultivation and fermentation of the acetone-butanol-producing bacteria were carried out as described above. After the production bacteria are inserted into the bioreactor, fermentation begins. When the butanol concentration in the fermentation broth reaches 5g / L, start the pump between the bioreactor and the membrane separation device, and bubble into the bioreactor, the pump makes the gas and the gasified butanol and acetone entrained by the gas And ethanol circulates in the closed space formed by the bioreactor and the membrane separation device. When the vaporized butanol, acetone and ethanol pass through one side of the separation membrane, they will dissolve and diffuse to the other side of the membrane, and be condensed and recovered . When the glucose concentration in the fermentation medium drops below 10g / L, add 400g / L o...

Embodiment 2

[0084] Example 2 Production of butanol, acetone and ethanol by gasification-osmosis coupled fermentation using corn stalk hydrolyzate as carbon source

[0085] The cultivation and fermentation of the acetone-butanol-producing bacteria were carried out as described above. After the production bacteria are inserted into the bioreactor, fermentation begins. When the butanol concentration in the fermentation broth reaches 5g / L, start the pump between the bioreactor and the membrane separation device, and bubble into the bioreactor, the pump makes the gas and the gasified butanol and acetone entrained by the gas And ethanol circulates in the closed space formed by the bioreactor and the membrane separation device. When the vaporized butanol, acetone and ethanol pass through one side of the separation membrane, they will dissolve and diffuse to the other side of the membrane, and be condensed and recovered . When the reducing sugar concentration in the fermentation medium drops be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com