Microspheres for composite heparin anticoagulation coating, preparation method and application

A technology of heparin and microspheres, which is applied in anticoagulation treatment, types of packaging items, special packaging items, etc., can solve problems such as differences in the performance of heparin coating materials, enhance anticoagulant function, reduce thrombosis, and improve the use of effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 Composite heparin anticoagulant coating microspheres

[0027] The invention discloses a composite heparin anticoagulant coating microsphere, which is a PLA-PEG-PLA heparin microsphere, which uses PLA-PEG-PLA as a carrier and cross-linked hydrazinocurcumin-heparin as the content.

[0028] The preparation method of the composite heparin anticoagulant coating microspheres, the steps are as follows:

[0029] 1) hydrazine curcumin is dissolved in the ethanol solution, is configured into the curcumin alcohol solution that concentration is 5mg / mL, adds MES buffer solution to the curcumin alcohol solution to reduce the curcumin concentration to 2.5mg / mL, then add to the curcumin alcohol solution Add 10g heparin to 300mL curcumin alcohol solution, then add 4g EDC and 4g NHS, stir for 1~2h, make the amino group in hydrazine curcumin fully react with heparin, put the reaction completed solution into the dialysis bag for dialysis for 24~72h After the dialysis is complete...

Embodiment 2

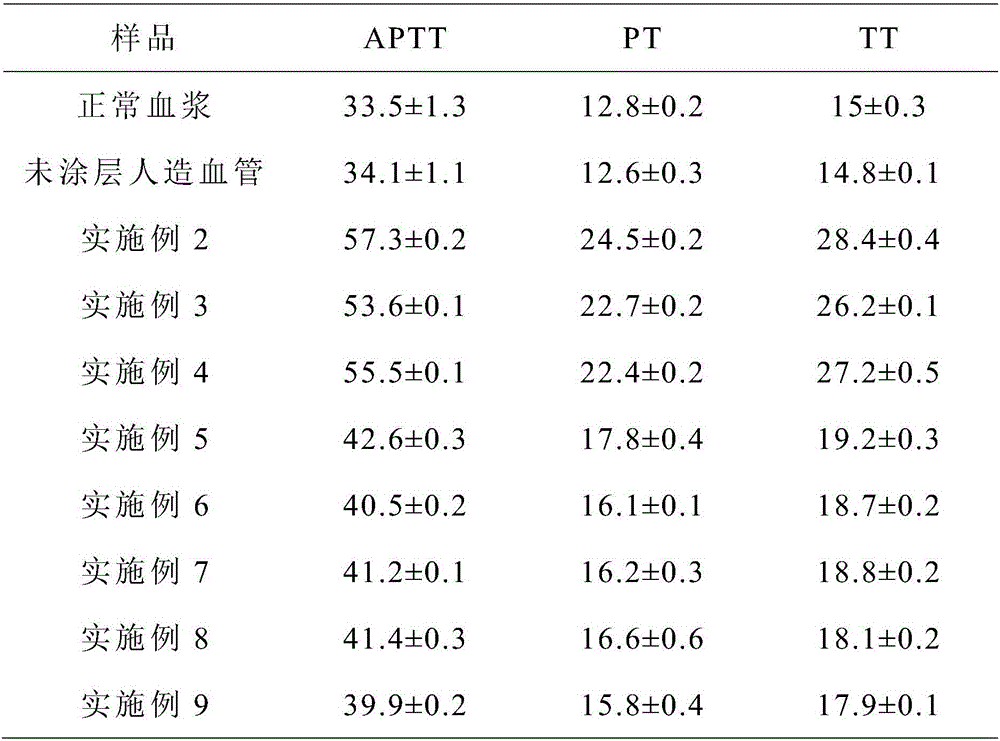

[0031] Embodiment 2 silk fibroin composite heparin microsphere anticoagulant coating

[0032] The preparation method of artificial blood vessel with silk fibroin composite heparin microsphere anticoagulant coating, the steps are as follows:

[0033] 1) Preparation method of silk fibroin: put 20-30g raw silk into 10-12L containing Na 2 CO 3 (2.12g / L) solution in boiling water for 20-30mins, then repeatedly rinse the boiled degummed silk with deionized water to remove residual sericin. Lay the washed silk protein fibers flat in a ventilated place to dry. Weigh 15-25g of dry silk fiber and dissolve it in 100-150mL LiBr solution (9.3M) at 60°C. After the dissolution is completed, use a dialysis bag to attack the silk protein solution for 36-72 hours. After the dialysis is completed, the solution is removed by centrifugation. Impurities are removed to obtain a silk fibroin macromolecular solution.

[0034] 2) The composite heparin anticoagulant coating microspheres prepared in ...

Embodiment 3

[0037] Example 3 Silk fibroin composite heparin microsphere anticoagulant coating

[0038] This example is basically the same as Example 2, except that the concentration of microspheres for heparin-combined anticoagulant coating in the silk fibroin-combined heparin microsphere anticoagulant coating solution is 0.7%wt, and the silk fibroin concentration is 5.6%wt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com