Preparation method of ultra-fine fiber material for preventing neutron radiation

A technology for preventing neutron radiation and ultra-fine fibers, applied in the field of spinning, can solve the problems of high price, many protection loopholes, poor air permeability, etc., and achieves strong neutron shielding ability, large protection area, and good air permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of the neutron radiation-proof ultrafine fiber material of the present embodiment, the steps are as follows:

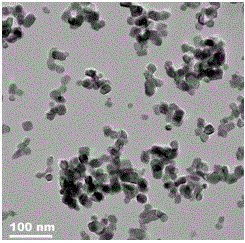

[0027] The microfiber material is sliced in PP and nano-B 4 C blend is used as raw material, titanate coupling agent and TAS-2A are used as additives, and PP / B is melt-blown 4 C blends are melt-spun, the nano-B 4 The average particle size of C is around 60nm.

[0028] The preparation method of the described anti-neutron radiation ultrafine fiber material, concrete steps are as follows:

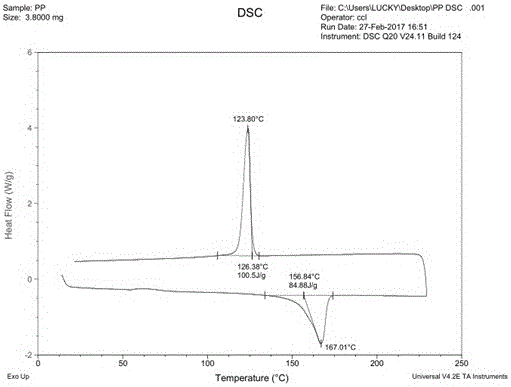

[0029] (1) PP / B 4 Preparation of C masterbatch: first mix PP slices and titanate coupling agent in a high-speed kneader. The performance parameters of PP slices are: melting point 167°C, under the condition of 260°C with a load of 2160g, PP slices in the masterbatch Melt finger 56g / 10min, when the temperature reaches 90℃ 4 Add C and TAS-2A, mix for 20 minutes, discharge and cool, melt and extrude with a twin-screw extruder to obtain PP / B 4 C maste...

Embodiment 2

[0033] The present embodiment provides a kind of preparation method of the anti-neutron radiation ultrafine fiber material, and the steps are as follows:

[0034] The microfiber material is sliced in PP and nano-B 4 C blend is used as raw material, titanate coupling agent and TAS-2A are used as additives, and PP / B is melt-blown 4 C blends are melt-spun, the nano-B 4 The average particle size of C is around 60nm.

[0035] The preparation method of the described anti-neutron radiation ultrafine fiber material, concrete steps are as follows:

[0036] (1) PP / B 4 Preparation of C masterbatch: first mix PP slices and titanate coupling agent in a high-speed kneader. The performance parameters of PP slices are: melting point 167°C, under the condition of 260°C with a load of 2160g, PP slices in the masterbatch The melting point is 40g / 10min, the relative molecular mass distribution width is less than 4-5, and when the temperature reaches 90°C, the nano-B 4 C and TAS-2A were added...

Embodiment 3

[0043] The present embodiment provides a kind of preparation method of the anti-neutron radiation ultrafine fiber material, and the steps are as follows:

[0044] The microfiber material is sliced in PP and nano-B 4 C blend is used as raw material, titanate coupling agent and TAS-2A are used as additives, and PP / B is melt-blown 4 C blends are melt-spun, the nano-B 4 The average particle size of C is around 60nm.

[0045] The preparation method of the described anti-neutron radiation ultrafine fiber material, concrete steps are as follows:

[0046] (1) PP / B 4 Preparation of C masterbatch: first mix PP slices and titanate coupling agent in a high-speed kneader. The performance parameters of PP slices are: melting point 167°C, under the condition of 260°C with a load of 2160g, PP slices in the masterbatch Melt finger at 60g / 10min, when the temperature reaches 90℃ 4 Add C and TAS-2A, mix for 20-30 minutes, discharge and cool, melt and extrude with a twin-screw extruder to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com