Reinforced polypropylene-carbonate biological material and high-through-hole-rate foaming product thereof, preparing method of reinforced polypropylene-carbonate biological material and preparing method of high-through-hole-rate foaming product

A polypropylene carbonate and biological material technology is applied in the field of reinforced polypropylene carbonate-based biological materials and high-porosity foamed products, and can solve the problem of weak intermolecular force of polypropylene carbonate and material formula. It can improve the cell structure and cell surface quality, improve the comprehensive performance, and simplify the processing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

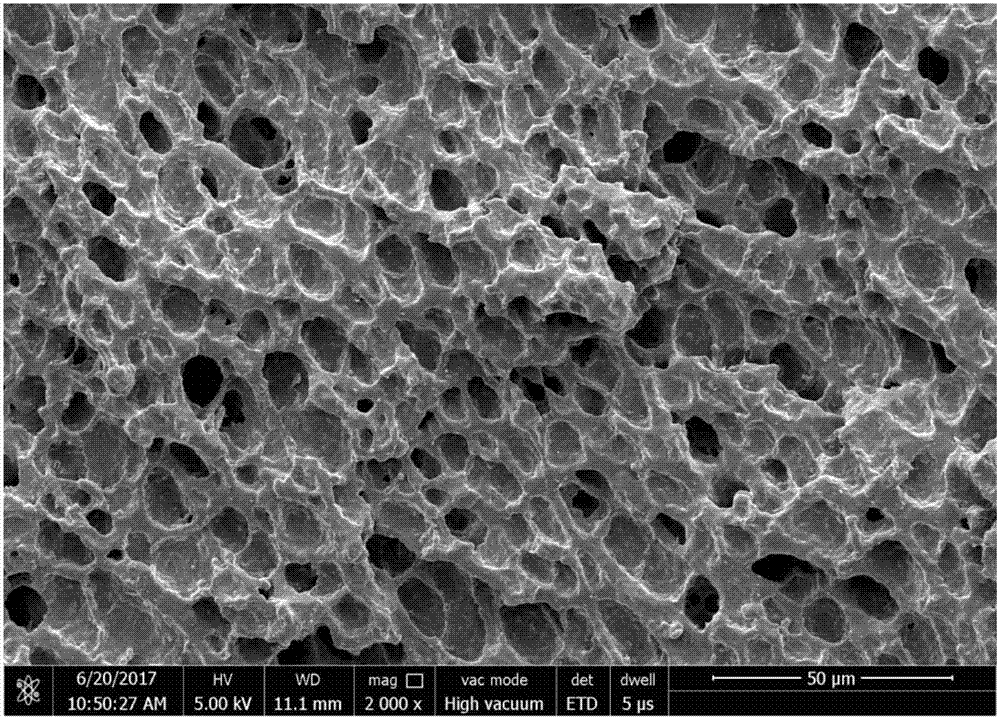

Embodiment 1

[0050] The preparation of enhanced polypropylene carbonate-based biomaterials specifically includes the following steps:

[0051] Take 45g of polypropylene carbonate, 5g of polylactic acid and 0.15g of CHINOX1010 antioxidant and dry them in an oven at 50°C for 24 hours, then mix them in a high-speed mixer for 3 minutes, and use an internal mixer to melt and blend the mixed materials , the processing temperature was 180° C., the rotation speed was 50 rpm, and the mixing time was 8 min, to obtain the enhanced polypropylene carbonate-based biomaterial.

[0052] The preparation of the enhanced polypropylene carbonate-based biomaterial foamed product specifically includes the following steps:

[0053] (1) Using a sheet mold with a thickness of 1 mm, crush the prepared reinforced polypropylene carbonate-based biomaterial and perform hot-press molding on a flat vulcanizer. The hot-pressing temperature is 180°C, and the hot-pressing time is 5 minutes. get sheet;

[0054] (2) The obt...

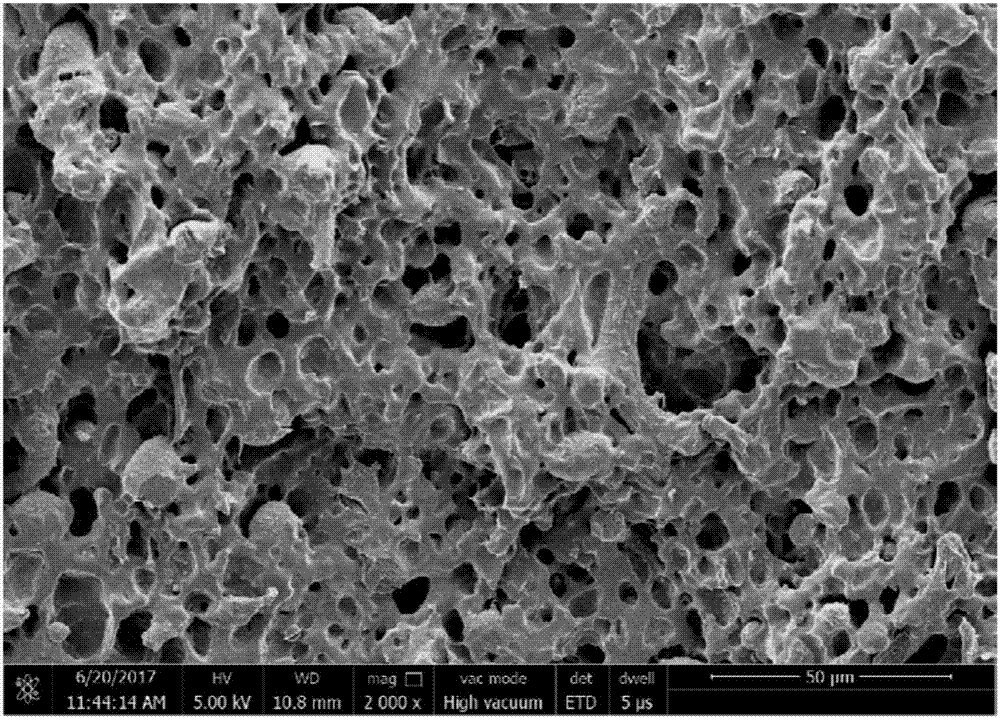

Embodiment 2

[0057] The preparation of enhanced polypropylene carbonate-based biomaterials specifically includes the following steps:

[0058] Take 35g of polypropylene carbonate, 15g of polylactic acid and 0.15g of the commercial brand name as CHINOX1010 antioxidant, dry in a 50°C oven for 24h, then mix in a high-speed mixer for 3min, and use an internal mixer to melt and blend the materials. The processing temperature was 180° C., the rotation speed was 50 rpm, and the mixing time was 10 minutes to obtain the enhanced polypropylene carbonate-based biomaterial.

[0059] The preparation of high-performance reinforced polypropylene carbonate-based foamed products specifically includes the following steps:

[0060] (1) Using a sheet mold with a thickness of 1 mm, the prepared reinforced polypropylene carbonate-based biomaterial was crushed and then hot-pressed on a flat vulcanizer. The hot-pressing temperature was 190°C and the hot-pressing time was 20 minutes. get sheet;

[0061] (2) The ...

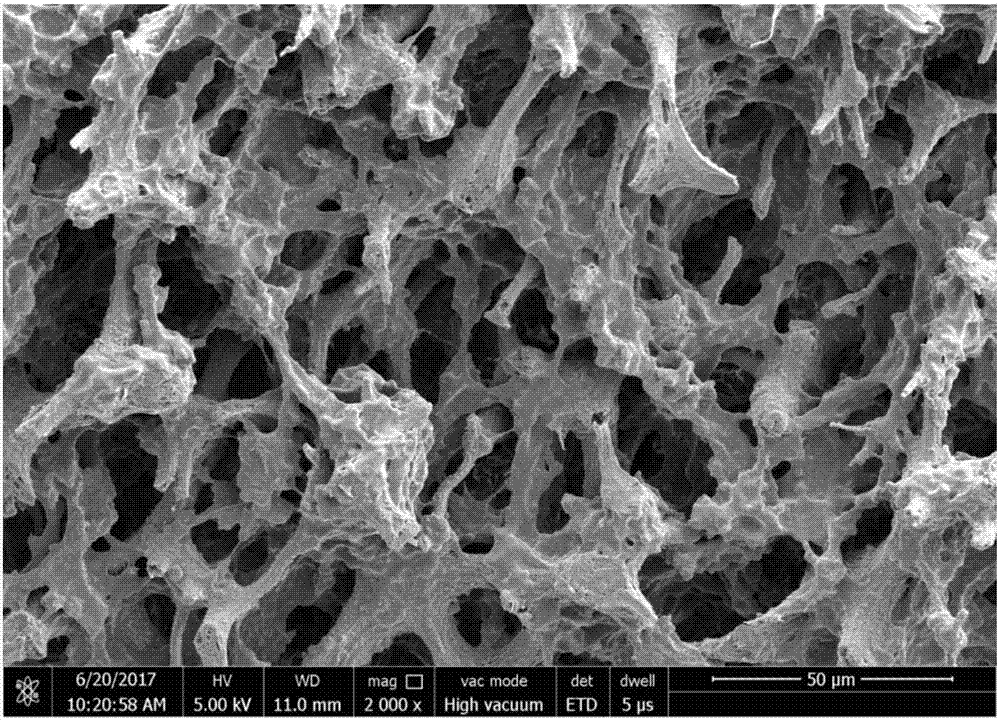

Embodiment 3

[0064] The preparation of enhanced polypropylene carbonate-based biomaterials specifically includes the following steps:

[0065] Take 25g of polypropylene carbonate, 25g of polylactic acid, and 0.15g of CHINOX1010 antioxidant, dry them in an oven at 50°C for 24 hours, then mix them in a high-speed mixer for 3 minutes, and use an internal mixer to melt and blend the mixed materials. , the processing temperature was 180° C., the rotation speed was 50 rpm, and the mixing time was 12 minutes, to obtain the enhanced polypropylene carbonate-based biomaterial.

[0066] The preparation of the high-through-porosity foamed product of the reinforced polypropylene carbonate-based biomaterial specifically includes the following steps:

[0067] (1) Using a sheet mold with a thickness of 1 mm, crush the prepared reinforced polypropylene carbonate-based biomaterial and perform hot pressing on a flat vulcanizer. The hot pressing temperature is 200 ° C, and the hot pressing time is 10 min. ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap