Online monitoring method and device for sludge-dewatering-technology ammonia and hydrogen sulfide

A technology for sludge dehydration and process, which is applied in the direction of measuring devices, air quality improvement, instruments, etc. It can solve the problem that the concentration and change of sulfur-containing gas cannot be given online in real time, and the emission of odorous gas cannot be determined. The application of sludge dehydration process, Emissions cannot be determined, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

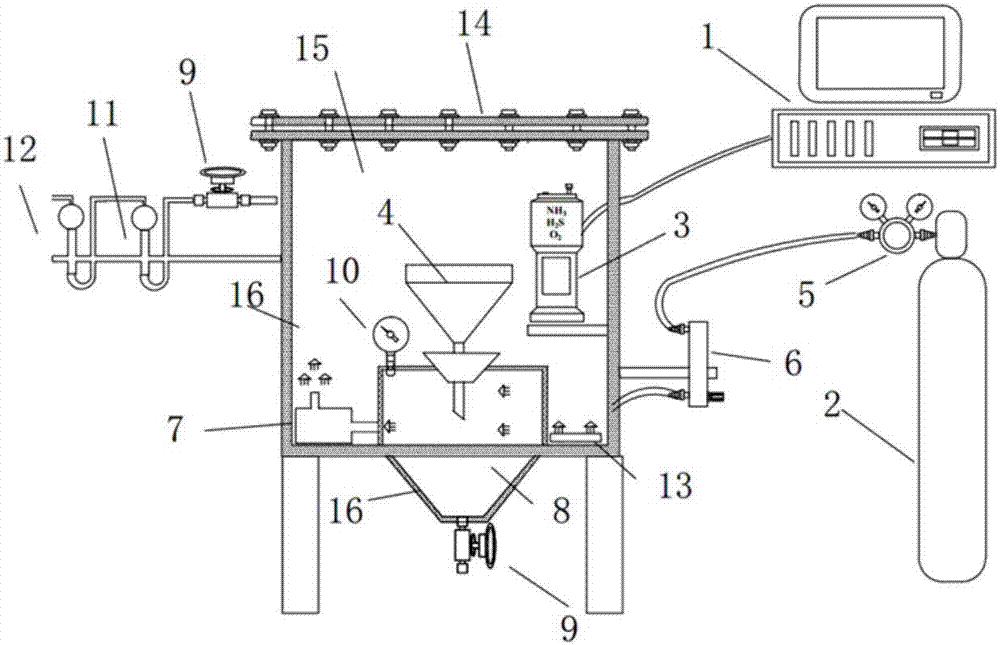

[0030] The present invention will be further described below in conjunction with example:

[0031] (1) Take 50mL of fresh sludge samples (anaerobic digestion sludge, excess sludge or primary sedimentation tank sludge), pour them into a Buchner funnel with filter paper, and the Buchner funnel and the inner chamber are sealed with rubber plugs. connection method.

[0032] (2) Turn on the O connected to the computer 2 , NH 3and H 2 After the S gas sensor, cover the sealing cap with the sealing ring. Open the gas discharge port and turn on the nitrogen source, the nitrogen enters the outer chamber through the aeration pan at the bottom, and the air is exhausted. When O 2 The sensor's display drops to 0.1%, and the gas vent and nitrogen source are closed.

[0033] (3) Turn on the micro-vacuum pump for dehydration, and the computer passes NH 3 and H 2 S gas sensor monitoring, real-time recording of sludge dehydration process NH in a confined space 3 and H 2 The concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com