Production method of squid skin collagen peptide instant noodle sandwich biscuits capable of nourishing skin

The technology of sandwich biscuit and production method is applied in the directions of dough processing, baked food, baking, etc., which can solve the problems of low yield of collagen peptides, affect the content of effective nutrients of enzymatic hydrolysis effect, etc., and achieve sweet taste and rich meal. Fiber and cholesterol lowering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

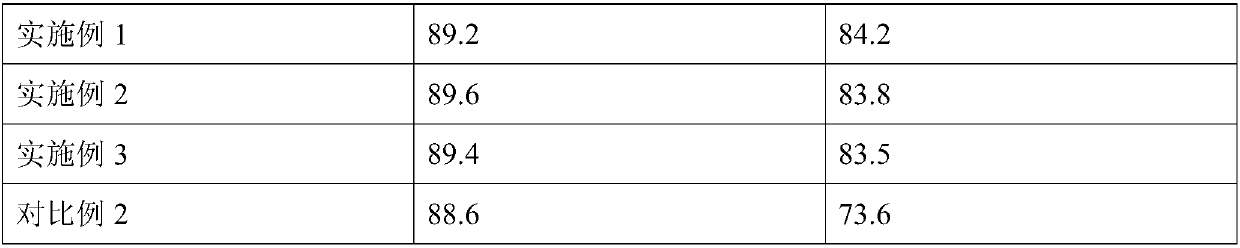

Embodiment 1

[0039] (1) Collagen peptide extraction from squid skin (all reagents used are food grade)

[0040] Thaw and wash the frozen squid skin, cut it into 1cm×1cm-1.5cm×1.5cm block squid skin; weigh 2kg squid skin, degrease with 100L mass concentration of 10% n-butanol for 2h; reconcentration is 0.3 mol / L anhydrous Na 2 CO 3 Soak in the solution to remove impurities, and use 0.3mol / L anhydrous Na 2 CO 3 Change the soaking solution once, and after changing it twice, wash it with deionized water to become neutral;

[0041] Soak squid skin in 100L of glacial acetic acid with a concentration of 0.5mol / L, add 0.02kg of pepsin for enzymolysis at room temperature for 4 hours, inactivate the enzyme at 95°C for 10 minutes, and filter to obtain enzymatic hydrolysis solution Ⅰ;

[0042] Add water to enzymolysis solution Ⅰ according to the mass ratio of enzymolysis solution Ⅰ and water 1:4, adjust the pH to 8 with 1mol / L NaOH, add 0.01kg of papain to hydrolyze at 55°C for 4h, inactivate the ...

Embodiment 2

[0063] (1) Collagen peptide extraction from squid skin (all reagents used are food grade)

[0064] Thaw the frozen squid skin, wash it, cut it into 1cm×1cm-1.5cm×1.5cm block squid skin; weigh 2kg squid skin, degrease with 300L mass concentration of 10% n-butanol for 4h; re-concentrate 0.5mol / L Anhydrous Na 2 CO 3 Soak in the solution to remove impurities, and use 0.5mol / L anhydrous Na every 3h 2 CO 3 The solution was replaced once with soaking solution and twice with anhydrous Na 2 CO 3 Afterwards, wash with deionized water to become neutral;

[0065] Soak the squid skin in 200L of 0.5mol / L glacial acetic acid, add 0.02kg of pepsin for enzymolysis at room temperature for 5h, inactivate the enzyme at 95°C for 10min, and filter to obtain enzymatic hydrolysis solution Ⅰ;

[0066] Add water to enzymolysis solution Ⅰ according to the mass ratio of enzymolysis solution Ⅰ to water 1:4, adjust the pH to 8 with 1mol / L NaOH, add 0.01kg papain for enzymolysis at 50°C for 5h, inact...

Embodiment 3

[0087] (1) Collagen peptide extraction from squid skin (all reagents used are food grade)

[0088] Thaw the frozen squid skin, wash it, cut it into 1cm×1cm-1.5cm×1.5cm block squid skin; weigh 2kg squid skin, degrease with 200L mass concentration of 10% n-butanol for 3h; anhydrous Na 2 CO 3 Soak in the solution to remove impurities, and change anhydrous Na every 2 hours 2 CO 3 Solution, Na used to remove impurities 2 CO 3 The concentration of the solution is 0.4mol / L, soaked three times and washed with deionized water to become neutral;

[0089] Soak squid skin in 150L of glacial acetic acid with a concentration of 0.5mol / L, add 0.02kg of pepsin for enzymolysis at room temperature for 4.5h, inactivate the enzyme at 95°C for 10min, and filter to obtain enzymatic hydrolysis solution Ⅰ;

[0090] Add water to enzymolysis solution Ⅰ according to the mass ratio of enzymolysis solution Ⅰ and water 1:4, adjust the pH to 8 with 1mol / L NaOH, add papain accounting for 0.5% of squid s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com