Processing method of novel mouth-contained tobacco products with black tea extracts

A technology for black tea extracts and snus products, which is applied in the fields of tobacco, tobacco processing, food science, etc., can solve the problems of different quantification, limited product application, different feelings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

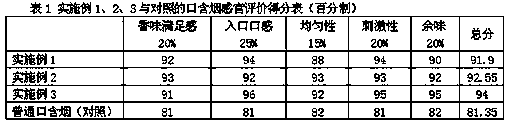

Examples

Embodiment 1

[0023] Preparation of raw materials: (1) Mix flue-cured tobacco powder produced in Yunnan and Burley tobacco powder produced in Hubei in a ratio of 1:2, grind to 20-35 mesh, extract with 60% food-grade alcohol solvent, and Concentrate in vacuum to obtain tobacco extract, prepare 40% tobacco extract (accounting for the mass ratio of the entire snus component, the same below), and its nicotine content is 0.65%; (2) Using black tea produced in Anhui as raw material, after heating Black tea extract obtained after water extraction, ceramic membrane coarse filtration, ultrafiltration membrane fine filtration, membrane concentration, vacuum low-temperature drying (20°C), and 30% black tea extract, in which the content of tea polyphenols is 21%, and the content of tea yellow (3) Prepare 18% stable (4) According to the ratio of 7% locust bean gum, 3% squash gum, and 2% tamarind polysaccharide gum, prepare 12% adhesive.

[0024] Processing of new snus products containing black tea extr...

Embodiment 2

[0026] Preparation of raw materials: (1) Mix flue-cured tobacco powder produced in Yunnan and Burley tobacco powder produced in Hubei in a ratio of 1:1, grind to 20-30 mesh, extract with 50% food-grade alcohol solvent, and Concentrate in vacuum to obtain tobacco extract, prepare 42% tobacco extract (accounting for the mass ratio of the entire snus component, the same below), and its nicotine content is 0.60%; (2) use black tea produced in Fujian as raw material, after heating The black tea extract obtained after water extraction, ceramic membrane coarse filtration, ultrafiltration membrane fine filtration, membrane concentration, and vacuum low-temperature drying (20°C) was prepared to prepare 35% black tea extract, of which the content of tea polyphenols was 22%, and the tea yellow (3) According to the ratio of 6% hydroxypropyl starch, 4% acetylated distarch phosphate, 2% polydextrose, and 1% calcium chloride, a 13% stabilizer was prepared; ( 4) Prepare a 10% adhesive accordi...

Embodiment 3

[0029]Preparation of raw materials: (1) Mix flue-cured tobacco powder produced in Yunnan and Burley tobacco powder produced in Hubei in a ratio of 2:1, grind to 22-28 mesh, extract with 55% food-grade alcohol solvent, and Concentrate in vacuum to obtain tobacco extract, prepare 35% tobacco extract (accounting for the mass ratio of the entire snus component, the same below), and its nicotine content is 0.65%; (2) Using black tea produced in Yunnan as raw material, after heating The black tea extract obtained after water extraction, ceramic membrane coarse filtration, ultrafiltration membrane fine filtration, membrane concentration, and vacuum low-temperature drying (20°C) is prepared to prepare 40% black tea extract, of which the content of tea polyphenols is 28%, and the content of tea yellow The protein content is 1.8%, the amino acid content is 6%; (3) According to the proportion of acid modified starch 6%, sodium carboxymethyl cellulose 6%, polydextrose 2%, sodium alginate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com