Green cast iron cutting machining method under condition of cooling and lubrication of outer cooling oils on water

A cooling lubrication and cutting technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of low penetration of cutting fluid, increase production cost, poor cooling effect, etc., and reduce tool chip accumulation. The effect of tumor generation, rapid heat reduction, and improvement of workpiece machining quality and tool life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

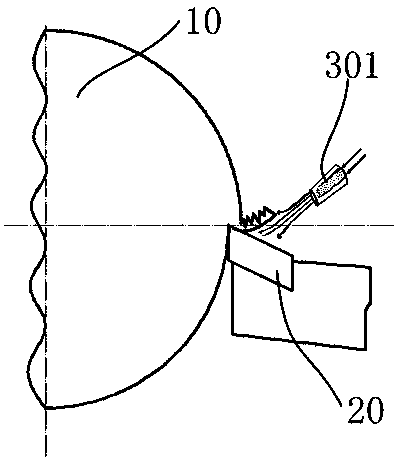

[0033] Such as figure 1 As shown, this embodiment provides a green cutting method for cast iron under the condition of external cooling oil film attached to water droplets for cooling and lubrication, including the following steps:

[0034] S1, fix the workpiece on the machine table;

[0035] S2. Turn on the oil film attached water drop equipment, and align the nozzle of the oil film attached water drop equipment with the tool; the nozzle includes the rake face nozzle, the distance between the rake face nozzle and the cutting edge of the tool is 30mm, and the angle between the rake face nozzle and the horizontal direction is 45°; the water output of the oil film attached water drop equipment is 0.6 L / h, the oil output is 0.02 L / h, and the gas pressure is 0.35 MPa when the compressed gas is mixed with the oil film attached water drop;

[0036] S3. Set the cutting speed to 70m / min, the feed rate to 0.15mm / r, and the cutting depth to 0.9mm according to the workpiece processing r...

Embodiment 2

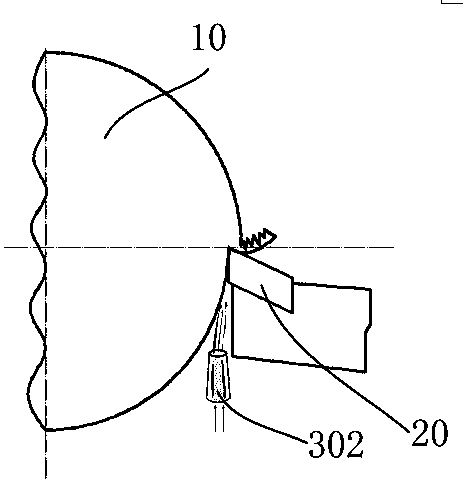

[0041] Such as figure 2 As shown, this embodiment provides a green cutting method for cast iron under the condition of external cooling oil film attached to water droplets for cooling and lubrication, including the following steps:

[0042] S1, fix the workpiece on the machine table;

[0043]S2. Turn on the oil film attached water drop equipment, and align the nozzle of the oil film attached water drop equipment with the tool; the nozzle includes the flank nozzle, the distance between the flank nozzle and the cutting edge of the tool is 35mm, and the included angle between the flank nozzle and the horizontal direction is 90°; the water output of the oil film attached water drop equipment is 1.2L / h, the oil output is 0.02 L / h, and the gas pressure is 0.35 MPa when the compressed gas is mixed with the oil film attached water drop;

[0044] S3. Set the cutting speed to 70m / min, the feed rate to 0.15mm / r, and the cutting depth to 0.9mm according to the workpiece processing requi...

Embodiment 3

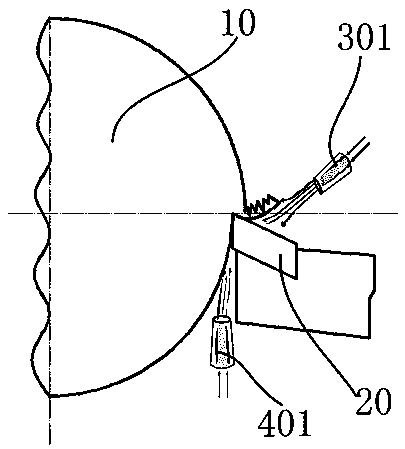

[0049] Such as image 3 As shown, this embodiment provides a green cutting method for cast iron under the condition of external cooling oil film attached to water droplets for cooling and lubrication, including the following steps:

[0050] S1, fix the workpiece on the machine table;

[0051] S2. Turn on the oil film attached water drop equipment, align the nozzle of the oil film attached water drop equipment with the tool; the nozzle includes the rake face nozzle and the flank face nozzle, the distance between the rake face nozzle and the cutting edge of the tool is 30mm, and the rake face nozzle and the horizontal The included angle of the direction is 45°, the distance between the flank nozzle and the cutting edge of the tool is 35mm, and the included angle between the flank nozzle and the horizontal direction is 90°; the water output of the oil film attached water droplet equipment is 1.2L / h, and the oil output is 0.02 L / h, the gas pressure is 0.35 MPa when the compressed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com