Carbon sliding block used for maglev train

A magnetic levitation train and carbon slider technology, applied in electric vehicles, vehicle components, power collectors, etc., can solve the problems of parking conductivity, edge drop, block drop, large friction coefficient, etc., and achieve good lubrication performance and extended use. The effect of long life and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

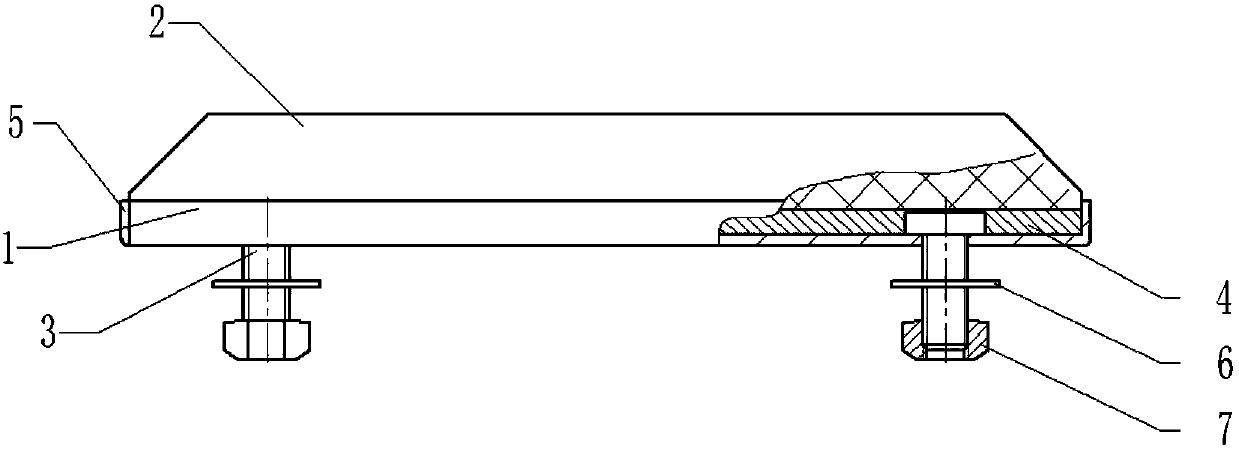

Image

Examples

Embodiment 1

[0137] 1. Preparation of carbon slider material

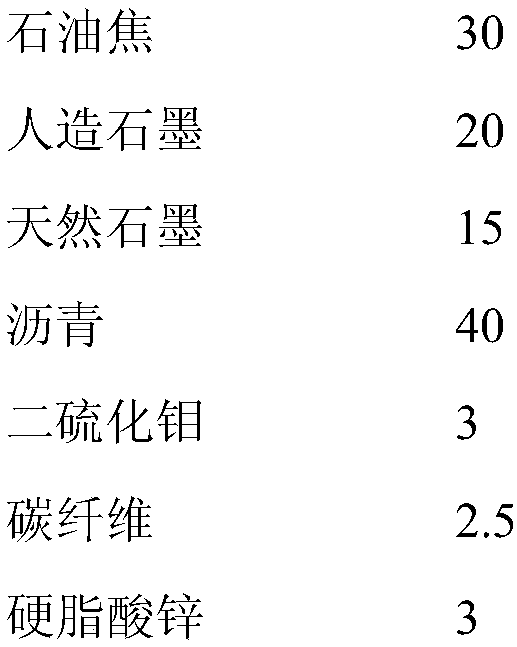

[0138] (1) Prepare materials according to the following proportions by weight

[0139]

[0140] (2) Raw material mixing

[0141] Continuously heat the mixing pot, when the temperature of the mixing pot reaches 120°C, add petroleum coke, artificial graphite, natural graphite, pitch, molybdenum disulfide, carbon fiber and zinc stearate into the mixing pot, stir and mix for 2 hours, and make It is uniform, and the powdery primary mixture is obtained;

[0142] Then, when the temperature of the heating pot reaches 150°C, add asphalt to the initial mixture, stir and mix for 1.5 hours to make it uniform, and obtain a powdery mixture;

[0143] (3) Compression treatment

[0144] Putting the powdery mixture in a mold for compression treatment to make a cylindrical material column;

[0145] (4) Curing treatment

[0146] Put the compressed material column in an oven at 100°C for curing treatment, the treatment time is 14 hours, and...

Embodiment 2

[0166] 1. Preparation of carbon sliders

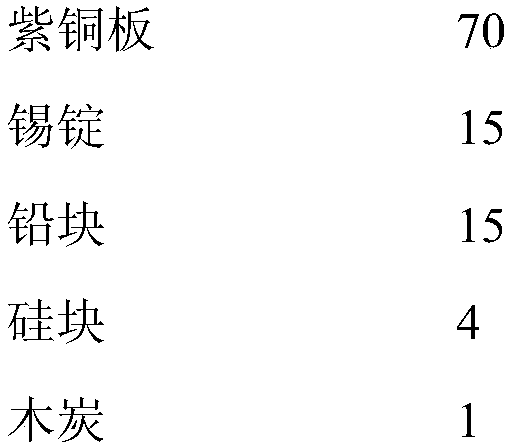

[0167] (1) Prepare materials according to the following proportions by weight

[0168]

[0169] (2) Raw material mixing

[0170] Continue heating the mixing pot, when the temperature of the mixing pot reaches 125°C, add petroleum coke, artificial graphite, natural graphite, pitch, molybdenum disulfide, carbon fiber and zinc stearate into the mixing pot, stir and mix for 2.3 hours, Make it uniform to obtain a powdery primary mixture;

[0171] Then, when the temperature of the heating pot reaches 145°C, add asphalt to the initial mixture, stir and mix for 1.2 hours to make it uniform, and obtain a powdery mixture;

[0172] (3) Compression treatment

[0173] Putting the powdery mixture in a mold for compression treatment to make a cylindrical material column;

[0174] (4) Curing treatment

[0175] Put the compressed material column in an oven at 105°C for curing treatment, the treatment time is 16 hours, and keep the material colu...

Embodiment 3

[0195] 1. Preparation of carbon sliders

[0196] (1) Prepare materials according to the following proportions by weight

[0197]

[0198] (2) Raw material mixing

[0199] Continue heating the mixing pot, when the temperature of the mixing pot reaches 115°C, add petroleum coke, artificial graphite, natural graphite, pitch, molybdenum disulfide, carbon fiber and zinc stearate into the mixing pot, stir and mix for 2.2 hours, Make it uniform to obtain a powdery primary mixture;

[0200] Then, when the temperature of the heating pot reaches 155°C, add asphalt to the initial mixture, stir and mix for 1.3 hours to make it uniform, and obtain a powdery mixture;

[0201] (3) Compression treatment

[0202] Putting the powdery mixture in a mold for compression treatment to make a cylindrical material column;

[0203] (4) Curing treatment

[0204] Put the compressed material column in an oven at 95°C for curing treatment for 17 hours to keep the material column at a constant tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com