A method and equipment for preparing polyvinyl alcohol/graphene conductive hybrid fibers based on wet-spinning magnetic field-induced migration technology

A polyvinyl alcohol and hybrid fiber technology, applied in the field of fiber materials, can solve the problems of loss of electrical conductivity, low concentration of addition, increase of modulus, etc., and achieve the effect of high electrical conductivity, easy operation, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

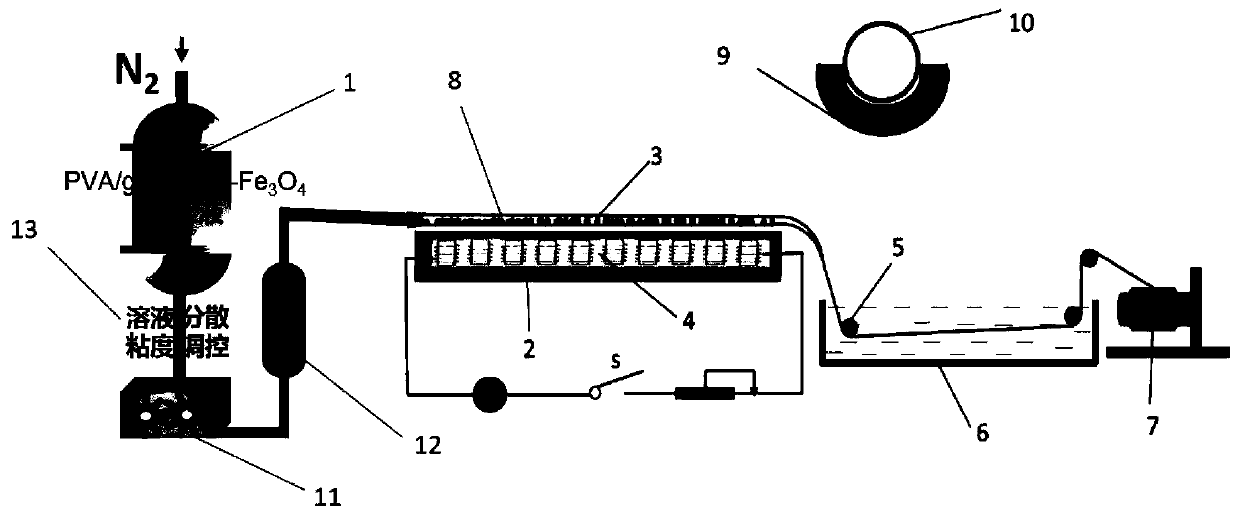

[0023] like figure 1 As shown, this embodiment provides a kind of equipment based on wet spinning magnetic field induced migration technology to prepare polyvinyl alcohol / graphene conductive hybrid fiber, comprising spinning liquid material tank 1 and metering pump 11, candle filter in turn through pipeline 12 connection, the candle filter 12 is connected with the capillary shear field offset channel 3 through the pipeline, the electromagnet 2 and the excitation coil 4 are arranged below the capillary shear field offset channel 3, and the coagulation bath 6 is connected with the capillary tube through the godet roller 5 The shear field offset channel 3 is connected to receive the fine flow in the capillary shear field offset channel 3, the coagulation bath 6 is equipped with a godet roller 5, and the coagulation bath 6 is connected to the winder 7 through the godet roller 5 .

Embodiment 2

[0025] (1) Dissolve 6g KH-550 in 200ml water, hydrolyze in 80℃ water bath for 2h, add 4g nano Fe 3 o 4 , continue to react for 2h, get nano-Fe 3 o 4 / KH-550 solution, then add 2 g of graphene powder, react at 80° C. for 2 h, and wash with deionized water and ethanol three times in sequence to obtain a magnetic nano-transfer unit.

[0026] (2) Dissolve 2.04g of the magnetic nano-transfer unit and 57g of polyvinyl alcohol PVA in step (1) in 300ml of water to obtain PVA / graphene-Fe in one pot 3 o 4 The spinning solution is put into the spinning solution material tank 1, and is transported to the capillary shear field offset channel 3 by the metering pump 11 and the candle filter 12, at N 2 Under the environment, the capillary shear magnetic field is offset, the capillary length-to-diameter ratio is 80, the capillary aperture is 0.2mm, and the magnetic field is an electric excitation field. The silk roll 5 is squeezed into the coagulation bath 6, coagulated, washed with water...

Embodiment 3

[0028] (1) Dissolve 2g KH-550 in 200ml water, hydrolyze in 80℃ water bath for 2h, add 2g nano Fe 3 o 4 , continue to react for 2h, get nano-Fe 3 o 4 / KH-550 solution, and then add 2 g of graphene powder, react at 90°C for 4 hours, and wash with deionized water and ethanol three times in sequence to obtain a magnetic nano-transfer unit.

[0029] (2) Dissolve 1.14g of the magnetic nano-transfer unit and 57g of polyvinyl alcohol PVA in step (1) in 300ml of water to obtain PVA / graphene-Fe in one pot 3 o 4 The spinning solution is put into the spinning solution material tank 1, and is transported to the capillary shear field offset channel 3 by the metering pump 11 and the candle filter 12, at N 2 Under the environment, the capillary shear magnetic field is offset, the capillary aspect ratio is 190, the capillary aperture is 0.8mm, the magnetic field is an electric excitation magnetic field, and the magnetic field strength is controlled by adjusting the current to 1T, and the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com