Preparation method of fiber structure

A technology of fiber structure and fiber film, which is applied in the field of preparation of fiber structure, can solve the problems of maintenance products occupying space and inconvenience, and achieve the effect of not occupying space, storage and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention discloses a method for preparing a fiber structure. The fiber structure is a film that can be dissolved in an aqueous solution. The skin care ingredients and texture modifiers are dissolved in a polar solvent to obtain skin care formula materials. Formulated materials are made into skin care products.

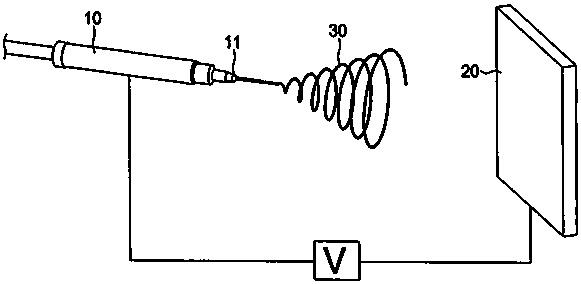

[0045] The processing technology is an electrostatic spinning technology, which is to spin the skin care formula material into a fiber film. The electrospinning technology has a spinning solution flow rate of 0.005-10 ml / min, a voltage of 5-45 KV, a working distance of 5-40 cm, and an ambient temperature range of 4° C. to 35° C. to make the fiber film.

[0046] The texture modifiers are various components for adjusting the color, texture, smell, and preservation of the product, which can be extracted or synthesized from animals, plants, minerals or microorganisms, and include pigments, fragrances, thickeners, and excipients , Surfactant, preservative, a...

Embodiment 1

[0066] 1. Preparation of spinning solution:

[0067] Weigh out 0.002g hyaluronic acid (MW=1440,000), 0.002g blue copper peptide (MW=340.38), 7g polyethylene oxide (PEO) (MW=900,000), dissolve in 10ml pure water, and add 1ml at the end The grapefruit seed antibacterial agent is evenly mixed.

[0068] 2. Fabrication process of fiber structure film:

[0069] Electrospin the mixed solution obtained in step 1, set the spinning rate to 0.03 mL / min, the voltage to 15kV, and the distance to 8cm. After 1 hour, a fibrous structure film can be formed on the collecting plate.

Embodiment 2

[0071] 1. Preparation of spinning solution:

[0072] Weigh 1g arbutin (MW=272.25), 1g mandelic acid (MW=152.14), 6g polyethylene oxide (PEO) (MW=900,000), dissolve in 9ml pure water, and finally add 1ml chamomile extract and mix evenly.

[0073] 2. Fabrication process of fiber structure film:

[0074] The mixed solution obtained in step 1 is subjected to electrospinning, the spinning rate is set to 0.25 mL / min, the voltage is 20kV, and the distance is 20cm. After 1 hour, a fibrous structure film can be formed on the collecting plate.

[0075] The production of the dry cosmetic moisturizing fiber film of the present invention. Electrospinning experiment parameters: the flow rate and electric field (voltage and working distance) of the electrospinning solution. Under the action of electric field spinning, the solution is sprayed on the metal collecting plate 20 through the nozzle 11 of the spraying device 10. A piece of ordinary photocopying paper is attached to the surface of the coll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com