Preparation method for cesium lead bromide inorganic perovskite thin film and photovoltaic device based on cesium lead bromide inorganic perovskite thin film

A photovoltaic device, inorganic calcium technology, applied in photovoltaic power generation, semiconductor devices, electrical components and other directions, can solve the problems of easy detachment of thin films and limited solubility of Br, and achieve good stability and repeatability, and good substrate coverage. , the effect of improving long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] CsPbBr in this example 3 Film Br 2 The steam heat injection vapor deposition preparation method comprises the following steps:

[0030] (1) CsPbI 3Precursor thin film preparation: take 0.55mmol of PbI 2 (0.254g) and 0.55mmol of CsI (0.143g) powder were dissolved in 1mL of DMF (N,N-dimethylformamide) solvent to form a yellow CsPbI with a concentration of 0.55mol / L 3 solution. In FTO / c-TiO 2 / m-TiO 2 spin-coated CsPbI 3 Precursor solution, spin-coating speed is 2000rpm, spin-coating time is 30s, and then the film is placed on a heating platform at 100°C for 10min to obtain yellow δ-phase CsPbI 3 Precursor film.

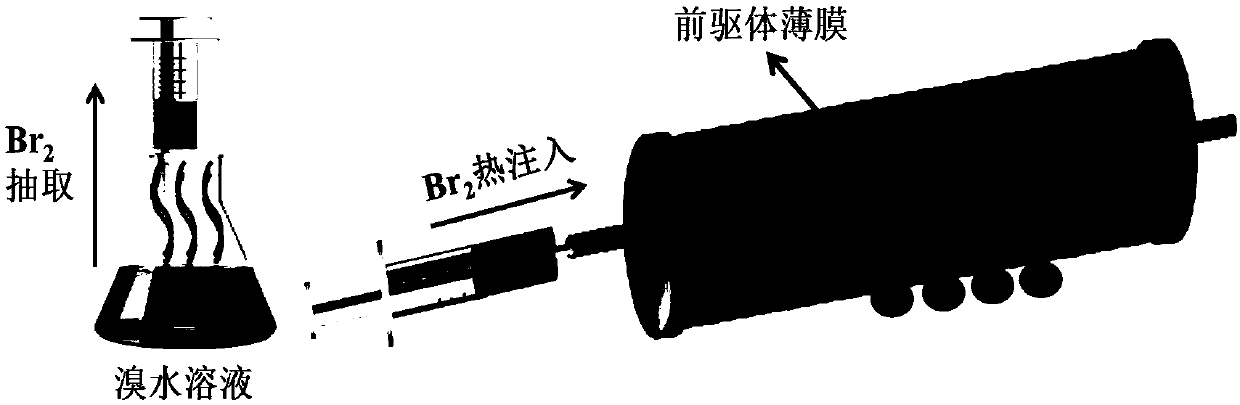

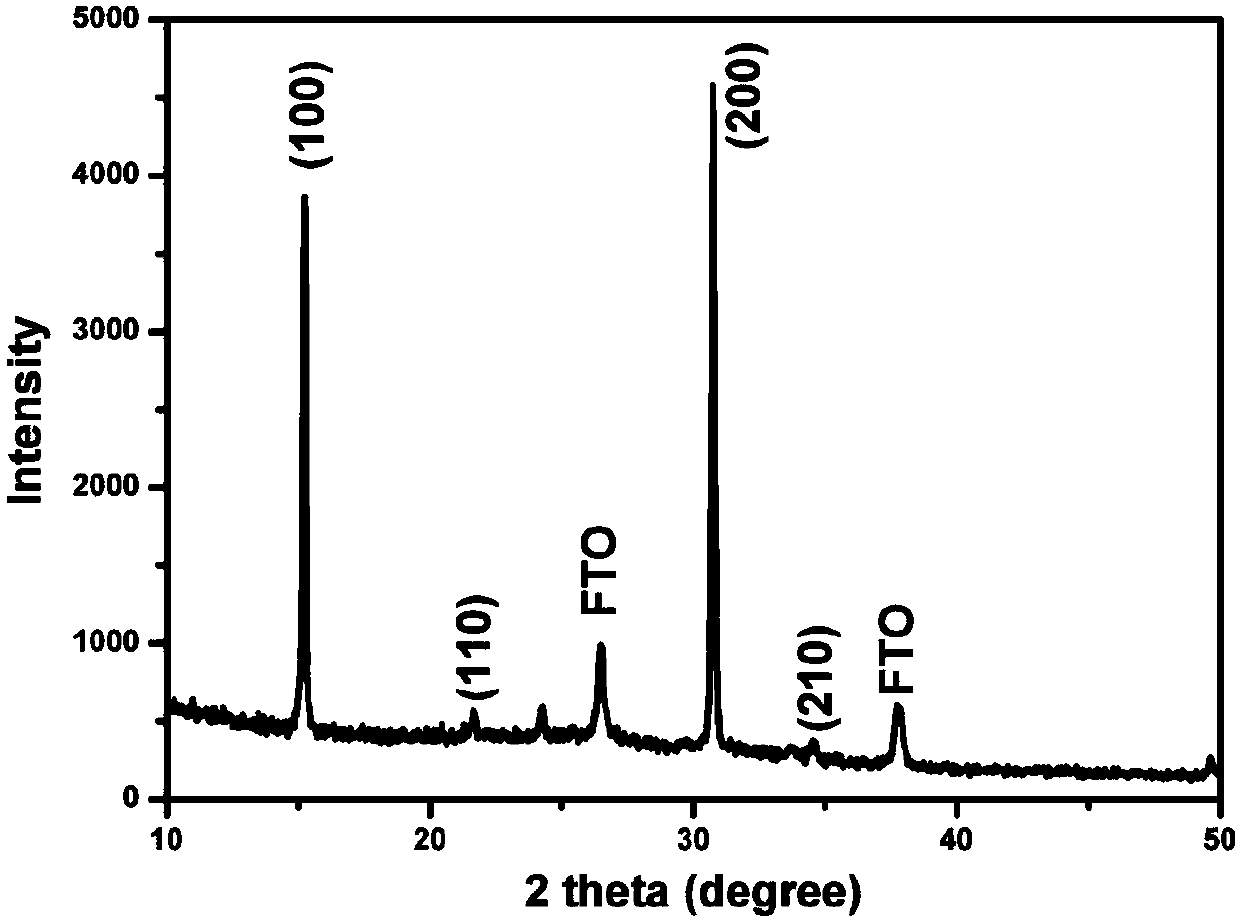

[0031] (2) CsPbBr 3 Film preparation: as figure 1 As shown, the yellow δ-phase CsPbI 3 The precursor film was transferred to a tube furnace, and after the quartz tube was pumped to 10Pa with a vacuum pump, the temperature of the tube furnace was raised to 150°C, and then 200mL of Br was taken with a syringe. 2 Put it into a quartz tube, react for 30 m...

Embodiment 2

[0045] This embodiment prepares CsPbBr in the same manner as in Example 1 3 film, the difference is that in step (2), the temperature of the tube furnace is set to 200°C.

[0046] After characterization, the CsPbBr obtained in this example 3 The film is similar to Example 1, all of which are black cubic phases, very dense and of high quality.

Embodiment 3

[0048] This embodiment prepares CsPbBr in the same manner as in Example 1 3 For thin films, the difference is that the temperature of the tube furnace in step (2) is set to 250°C.

[0049] After characterization, the CsPbBr obtained in this example 3 The film is similar to Example 1, all of which are black cubic phases, very dense and of high quality.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com