A microchannel wire cutting processing method

A cutting and micro-channel technology, applied in metal processing equipment, electric processing equipment, manufacturing tools, etc., can solve the problem of low specific surface area, and achieve the effect of increasing specific surface area, improving performance and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following describes the embodiments of the present invention in detail with reference to the accompanying drawings: This embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation and specific operation procedures, but the scope of protection of the present invention is not limited to the following Mentioned examples.

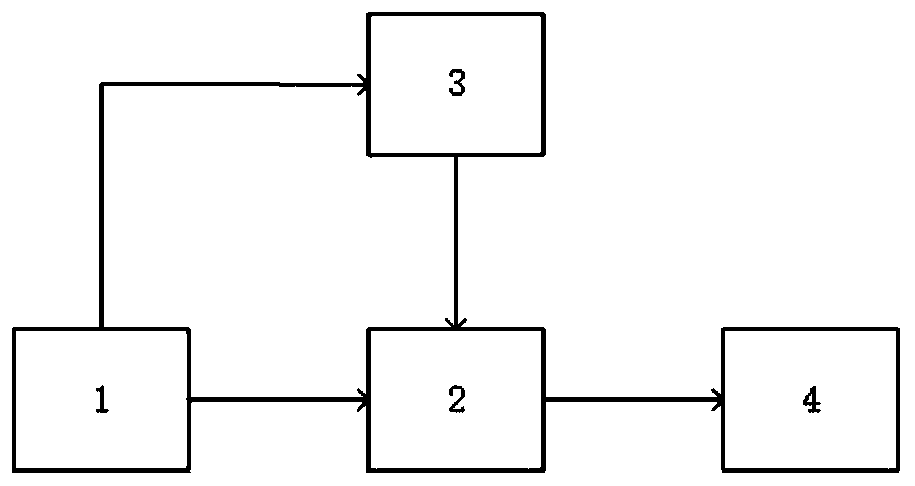

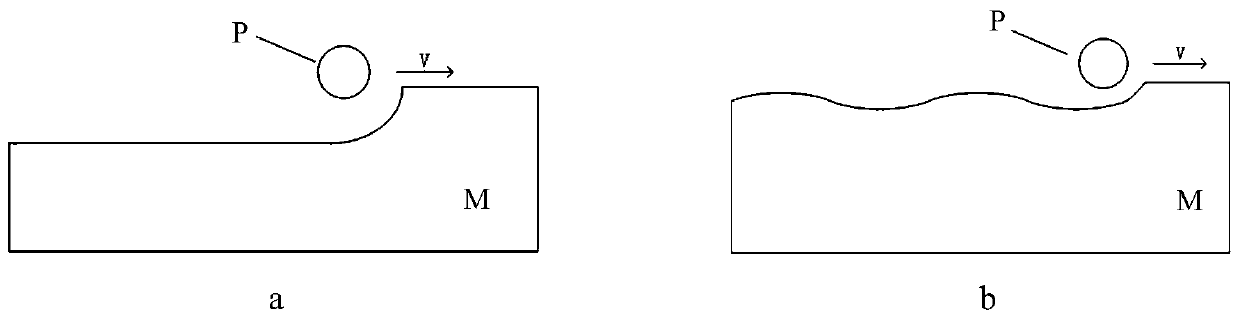

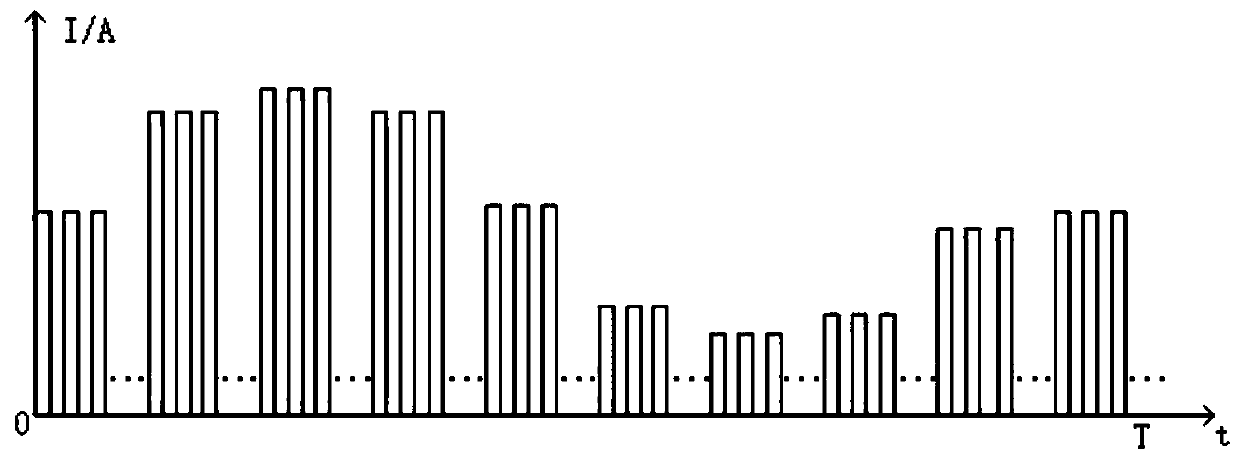

[0022] The invention is mainly used for the processing of microchannels, and the microchannels with cross-sectional shapes such as rectangles, triangles, circles, trapezoids, etc., are processed on the metal plate by the wire electric discharge method. Such as figure 1 As shown, the present invention adopts programmable pulse power supply for wire cutting processing, and the processing path is programmed and determined by the upper computer 1 according to the cross-sectional shape. During the machining process, the pulse controller 3 is used to perform online real-time control of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com