Waste mineral oil treatment process

A technology of waste mineral oil and treatment process, which is applied in the direction of only multi-stage series refining process, refining by filtration, and separation of dispersed particles, etc., which can solve the problems of difficult treatment, increased membrane work, and easy clogging of the membrane. Achieve the effect of good fluidity, enhanced fluidity, and not easy to clog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In order to achieve the above object, the basic scheme of the present invention is as follows:

[0036] The waste mineral oil pretreatment process of the present invention is suitable for treating waste engine oils such as lubricating oil for locomotives, lubricating oil for transmission equipment, and industrial hydraulic oil.

[0037] Light oil refers to gasoline and diesel oil in the upper waste oil; non-condensable gas refers to air, hydrogen, nitrogen, lubricating oil vapor, etc. mixed in the refrigeration system. These gases circulate in the system with the refrigerant, do not condense with the refrigerant, and do not produce refrigeration effect.

[0038] The clear liquid in the present invention is unbleached primary lubricating oil with a viscosity of about 30-40cSt at 40°C; the concentrated liquid is black lubricating oil, viscosity modifier and residual additives with a viscosity of about 130-140cSt at 40°C.

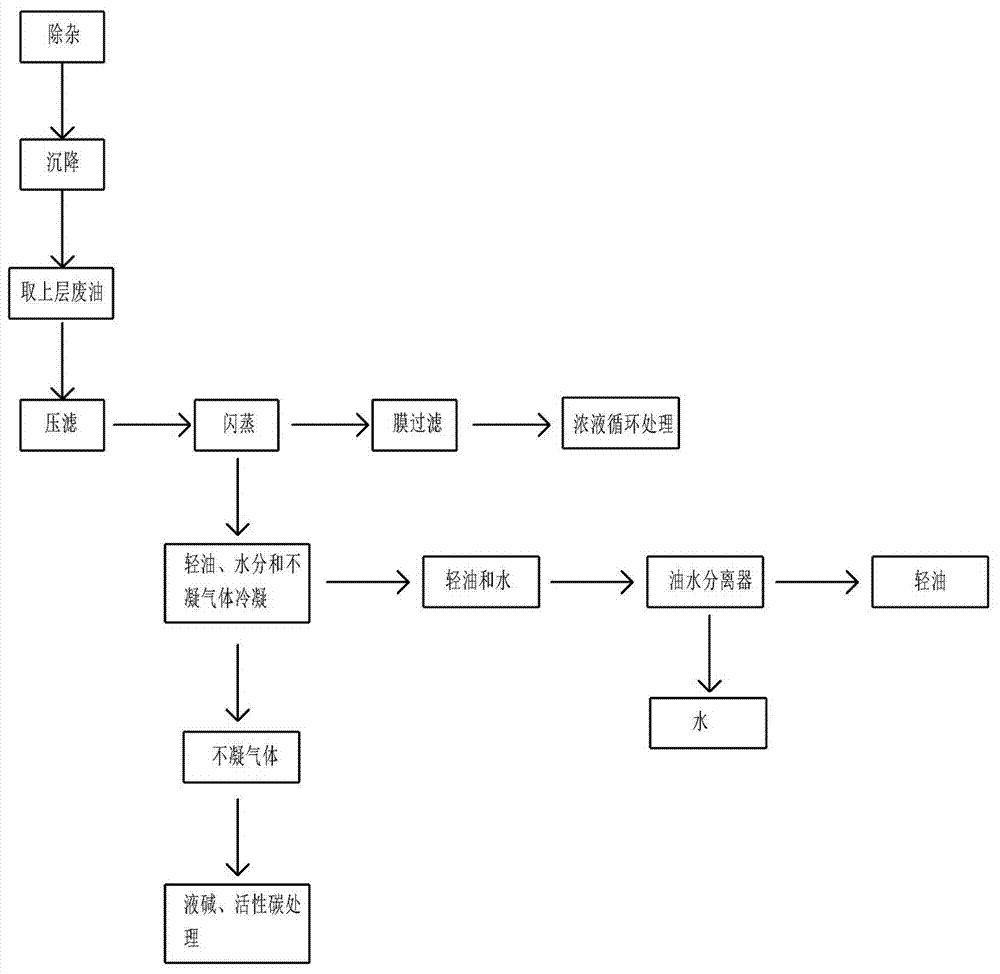

[0039] Such as figure 1 As shown, the waste min...

Embodiment 2

[0048] The difference between this embodiment and embodiment 1 is:

[0049] The waste mineral oil treatment process includes the following treatment steps:

[0050] Step 1, impurity removal: put the collected waste mineral oil into the waste oil storage tank, and use a basket filter to filter out large-sized solid impurities in the waste mineral oil. The inside of the basket filter is an 80-mesh stainless steel filter. network.

[0051] Step 2, settling: add liquid caustic soda to the waste mineral oil in step 1 to neutralize it; add steam to heat under stirring state, the structure adopts the method of heating the inner coil at the upper end and the jacket at the bottom of the tank, and the equipped The use of anchor stirring at the beginning of settlement effectively ensures that the material is fully heated; when the steam heating temperature rises to 60°C, stop stirring, continue to heat up to 70°C, and maintain it within the temperature range of 70°C, and then settle. Th...

Embodiment 3

[0058] The difference between this embodiment and embodiment 1 is:

[0059] The waste mineral oil treatment process includes the following treatment steps:

[0060] Step 1, impurity removal: put the collected waste mineral oil into the waste oil storage tank, and use a basket filter to filter out large-sized solid impurities in the waste mineral oil. The inside of the basket filter is an 80-mesh stainless steel filter. network.

[0061] Step 2, settling: add liquid caustic soda to the waste mineral oil in step 1 to neutralize it; add steam to heat under stirring state, the structure adopts the method of heating the inner coil at the upper end and the jacket at the bottom of the tank, and the equipped The use of anchor stirring at the beginning of the settlement effectively ensures that the material is fully heated; when the steam heating temperature rises to 65°C, stop stirring, continue to heat up to 70°C, and maintain it within the temperature range of 75°C, and then settle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com