Anthraquinone dihydroxy sodium salt-graphene compound and preparation and application thereof

A technology of anthraquinone dihydroxy sodium salt and hydroxyanthraquinone disodium, which is applied in the field of sodium ion battery materials, can solve the problems of not improving the electrochemical performance of the cathode material of sodium batteries, and achieve good cycle stability, rate performance, and yield The effect of high and high discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

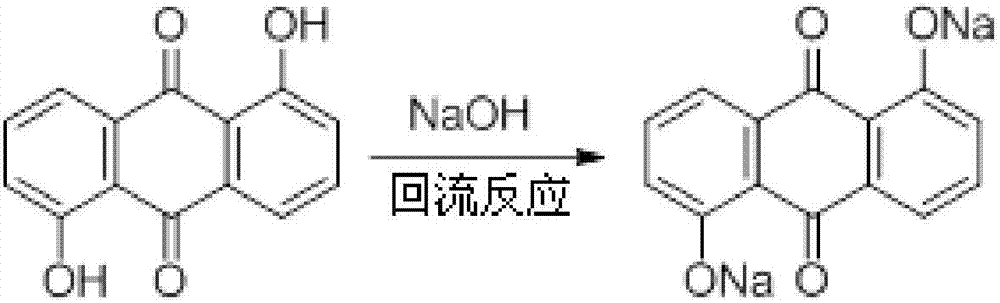

[0036] (1) Dissolve 1.04g of 1,5-dihydroxyanthraquinone (DHAQ) in 10mL of N,N-dimethylformamide and stir at 80°C, then gradually add 20mL of 1mol / L NaOH solution dropwise. Continue to reflux and stir for 8 hours and stop heating, remove the mother liquor with a rotary evaporator to obtain a purple-black precipitate, wash the obtained precipitate with deionized water, and then dry it in a vacuum oven at 80°C for 12 hours to obtain 1,5-dihydroxyanthraquinone disodium ( DHAQNa).

[0037] (2) Take 0.1g DHAQNa prepared in step (1) and grind it in a quartz grinding pot for half an hour and disperse it together with 0.05g graphene into 15mL of N-methylpyrrolidone solvent, put it into a quartz ball mill jar and mill it for 3 hours to make Cloudy liquid.

[0038] (3) The turbid liquid obtained in step (2) was transferred to a vacuum drying oven, and the co-precipitation was vacuum-dried at 80° C. for 24 hours to obtain disodium hydroxyanthraquinone-graphene complex (DHAQNa / G).

[003...

Embodiment 2

[0046] (1) Dissolve 1.04 g of 1,5-dihydroxyanthraquinone (DHAQ) in 10 mL of dichloromethane and stir at 80° C., then gradually add 10 mL of 1 mol / L NaOH solution dropwise. Continue to reflux and stir for 8 hours and stop heating, remove the mother liquor with a rotary evaporator to obtain a purple-black precipitate, wash the obtained precipitate with deionized water, and then dry it in a vacuum oven at 60°C for 12 hours to obtain 1,5-dihydroxyanthraquinone disodium ( DHAQNa).

[0047] (2) Take 0.05g DHAQNa prepared in step (1) and grind it in a quartz grinding pot for half an hour and disperse it together with 0.05g graphene into 10mL of N-methylpyrrolidone solvent, put it into a quartz ball mill jar and mill it for 2 hours to make Cloudy liquid.

[0048] (3) The turbid liquid obtained in step (2) was transferred to a vacuum drying oven, and the co-precipitation was vacuum-dried at 60° C. for 24 hours to obtain disodium hydroxyanthraquinone-graphene complex (DHAQNa / G).

[00...

Embodiment 3

[0055] (1) Dissolve 1.04 g of 1,5-dihydroxyanthraquinone (DHAQ) in 10 mL of methanol and stir at 80° C., then gradually add 30 mL of 1 mol / L NaOH solution dropwise. Continue to reflux and stir for 12 hours and stop heating, remove the mother liquor with a rotary evaporator to obtain a purple-black precipitate, wash the obtained precipitate with deionized water, and then dry it in a vacuum oven at 90°C for 24 hours to obtain 1,5-dihydroxyanthraquinone disodium ( DHAQNa).

[0056] (2) Take 0.15g DHAQNa prepared in step (1) and grind it in a quartz grinding pot for half an hour and disperse it together with 0.05g graphene into 10mL of N-methylpyrrolidone solvent, put it into a quartz ball mill jar and mill it for 5 hours to make Cloudy liquid.

[0057] (3) The turbid liquid obtained in step (2) was transferred to a vacuum drying oven, and the co-precipitation was vacuum-dried at 85° C. for 24 hours to obtain disodium hydroxyanthraquinone-graphene complex (DHAQNa / G).

[0058] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com