A kind of mixing emulsification method and feeding method of catalytic feed oil

A feeding method and raw oil technology, applied in the direction of mixing methods, catalytic cracking, chemical instruments and methods, etc., can solve the problem of low gasification rate at the inlet of riser reactor, coking of nozzle of riser reactor, dry gas and coke production The problems such as the increase of oil rate can be solved, and the effect of shortening the gasification time, high degree of dispersion of oil droplets and short vaporization time can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

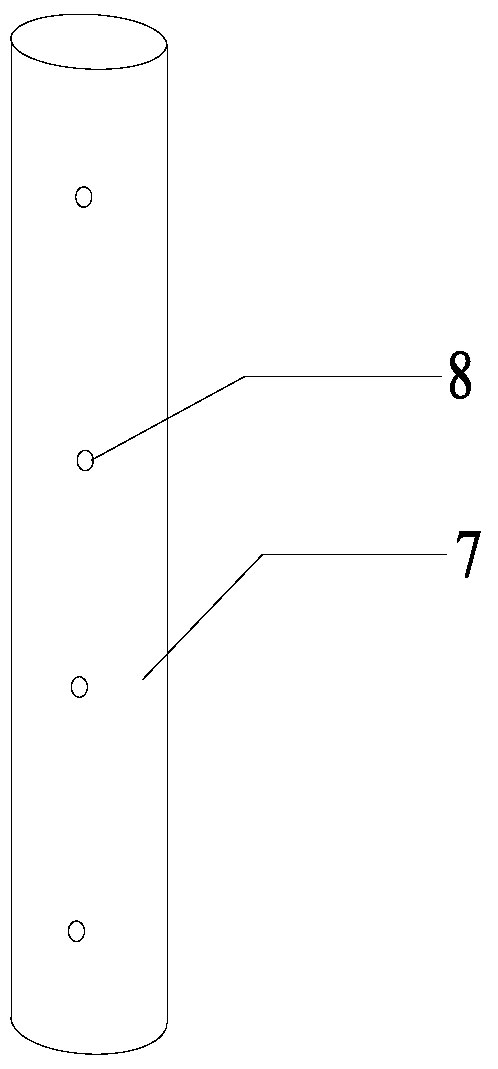

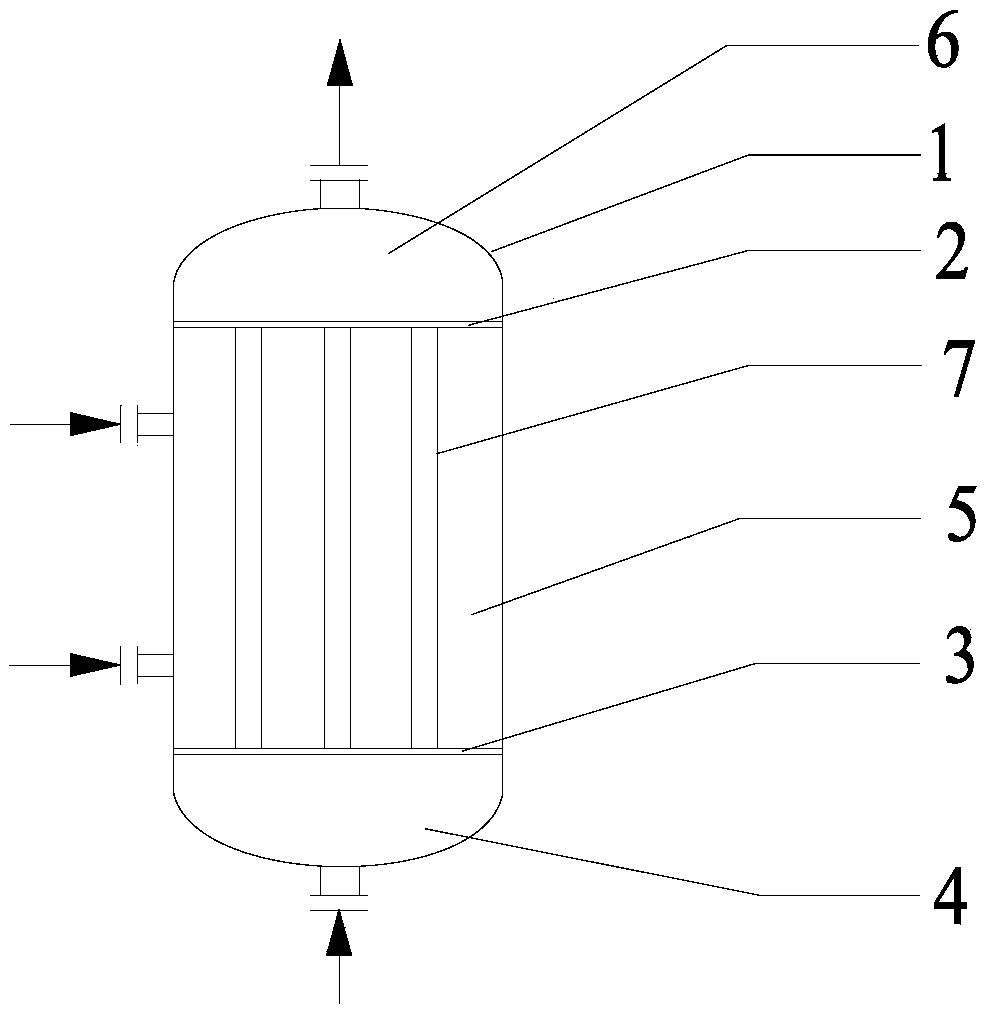

[0035] A specific embodiment, such as Figure 1-3 As shown, the step of the water-in-oil emulsification includes: sending the catalytic raw material oil into the distribution emulsification pipe 7 from the inlet at one end of the distribution emulsification pipe 7 and from the holes provided on the wall of the distribution emulsification pipe 7 8, after the emulsified water is mixed, the distribution emulsification pipe 7 is sent out from the outlet at the other end of the distribution emulsification pipe 7; wherein, the aperture of the channel 8 is 1-60000 nanometers, preferably 1-30000 nanometers, more preferably 1-10000 nanometers nanometer, more preferably 1-5000 nanometer.

[0036] In the present invention, since the raw material oil is dispersed into emulsified oil droplets with a particle size of micronano level by the emulsified water distributed in the emulsification pipe before the catalytic reactor nozzle is fed, and the particle size of the emulsified raw material ...

Embodiment

[0051] In this example, a catalytic cracking experiment was carried out in a certain refinery, the processing capacity of the adopted riser reactor was 600,000 tons / year, and the height of the riser reactor was 30 meters.

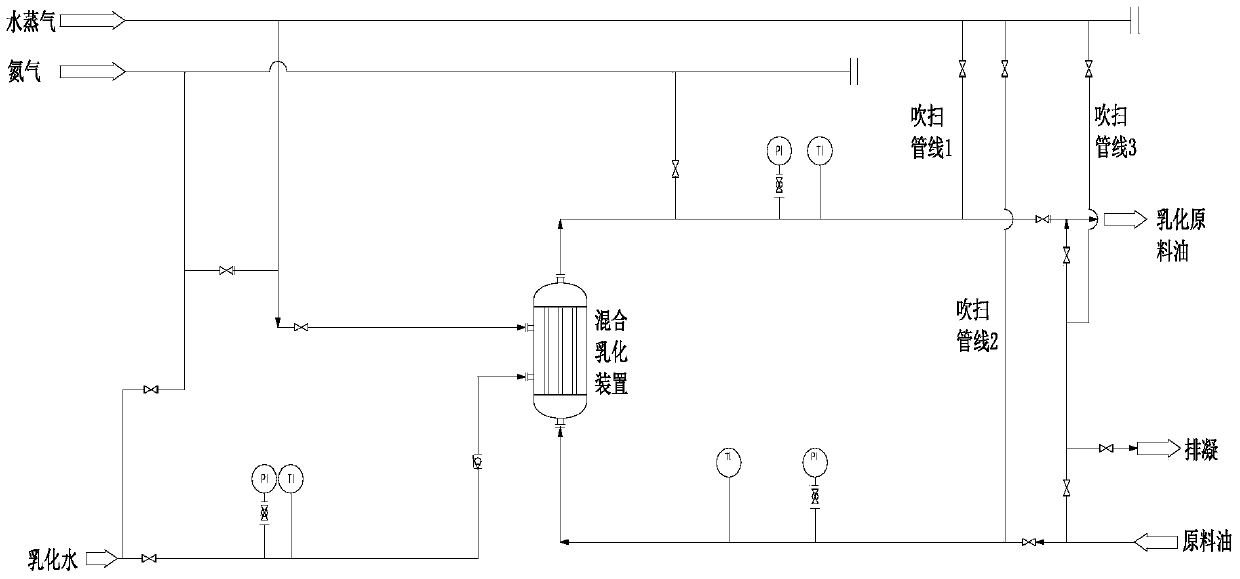

[0052] use as image 3 The mixed emulsification system shown performs mixed emulsification. The parameters of the distribution emulsification pipe are: the length is 1000 mm, the inner diameter is 400 mm, and the outer diameter is 450 mm. The number of distribution emulsification pipes is 37, and the porosity of a single distribution emulsification pipe is 30%, the material of the distribution emulsification pipe is a composite material with aluminum oxide as the main material, and the pore diameter of the channel is 10000 nanometers (10 microns).

[0053] Raw oil composition: 35% vacuum residue, density: 0.9586, 65% wax oil, density 0.8937; emulsified water: sulfur-containing ammonia sewage from FCC plant.

[0054] The condition of water-in-oil emulsifica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com