Preparation method of graphene quantum dot supported Ag-TiO2 nano array

A technology of graphene quantum dots and nano-arrays, applied in the direction of light water/sewage treatment, etc., can solve problems such as toxicity, unsatisfactory visible light response performance, and complicated preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

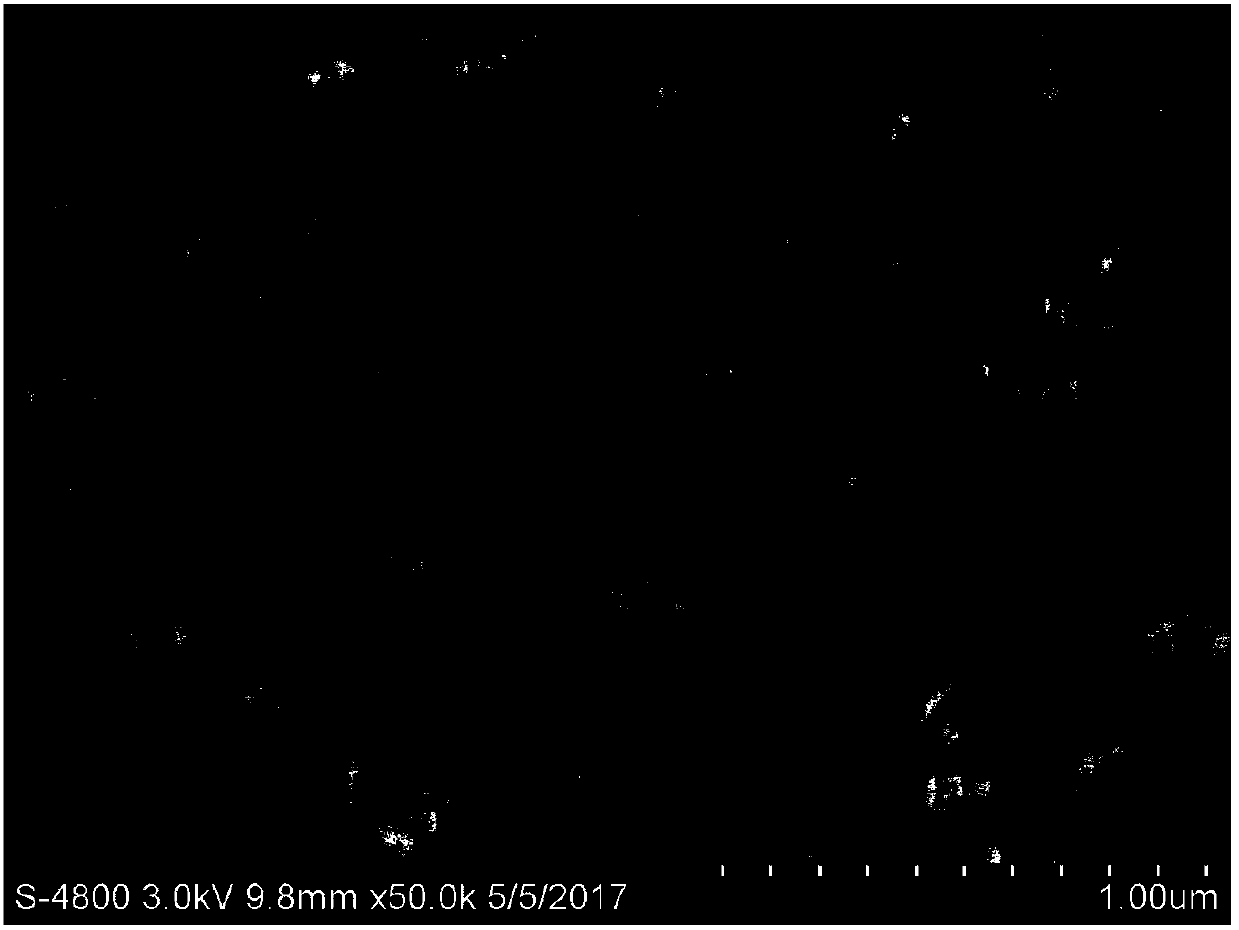

Image

Examples

Embodiment 1

[0030] A graphene quantum dot supported Ag-TiO 2 The preparation method of nanometer array specifically comprises the following steps:

[0031] The present invention uses FTO conductive glass (1 * 1.5 * 0.21cm) as substrate, and FTO conductive glass is ultrasonically cleaned in acetone and deionized water respectively for 20 minutes, to remove organic pollutants and impurities on the surface of the FTO film, and the cleaned FTO Conductive glass is dried in an atmosphere at 60°C.

[0032] Mix 20 ml of hydrochloric acid, 20 ml of deionized and 0.68 ml of butyl titanate, and after stirring magnetically at room temperature for 30 minutes, transfer the solution to a 50 ml autoclave lined with polytetrafluoroethylene, and place the cleaned FTO conductive glass Tilt in the autoclave, put the autoclave into an oven at 150°C, react for 10 hours, cool to room temperature naturally, take out the sample, wash the sample with deionized water several times, and dry the sample in an oven at...

Embodiment 2

[0039] The steps in this embodiment two are basically the same as those in embodiment one, the difference is:

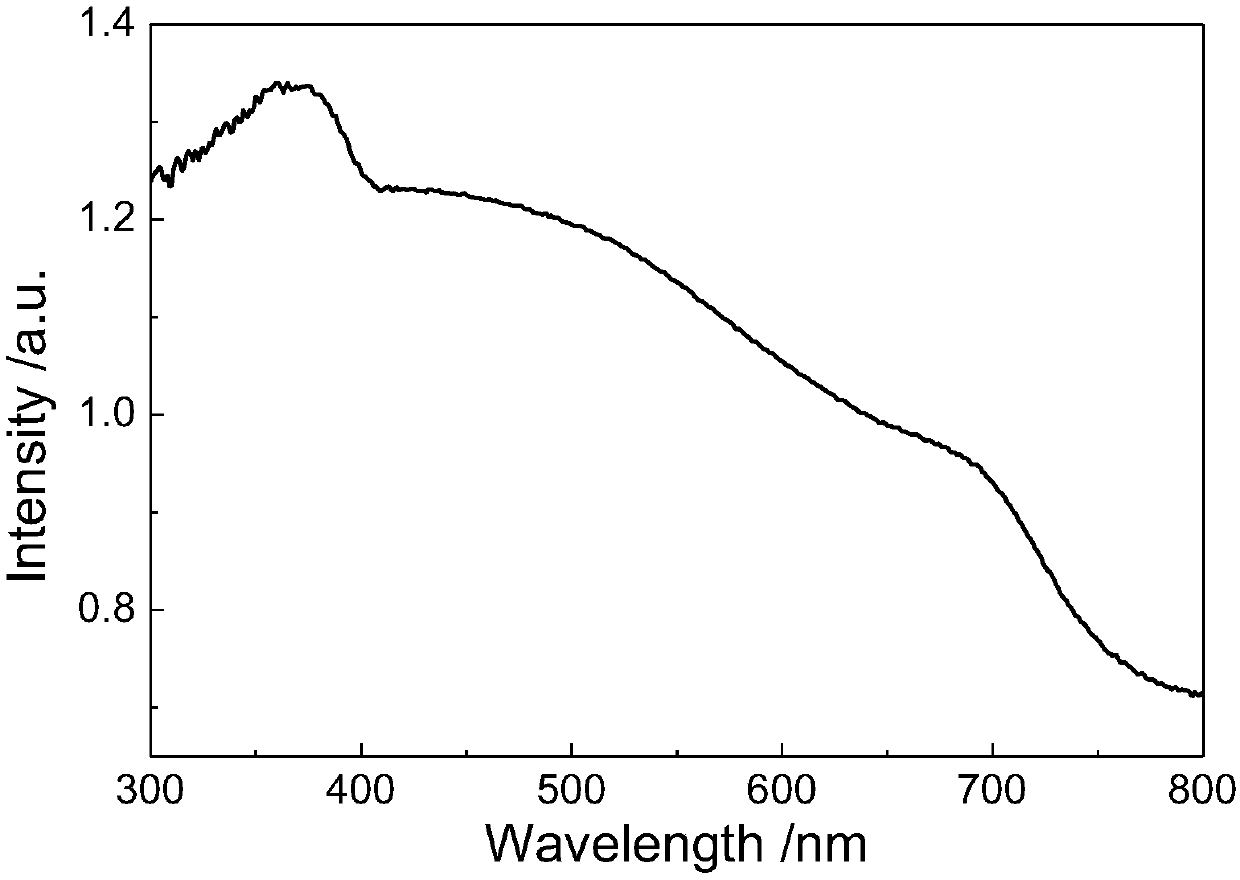

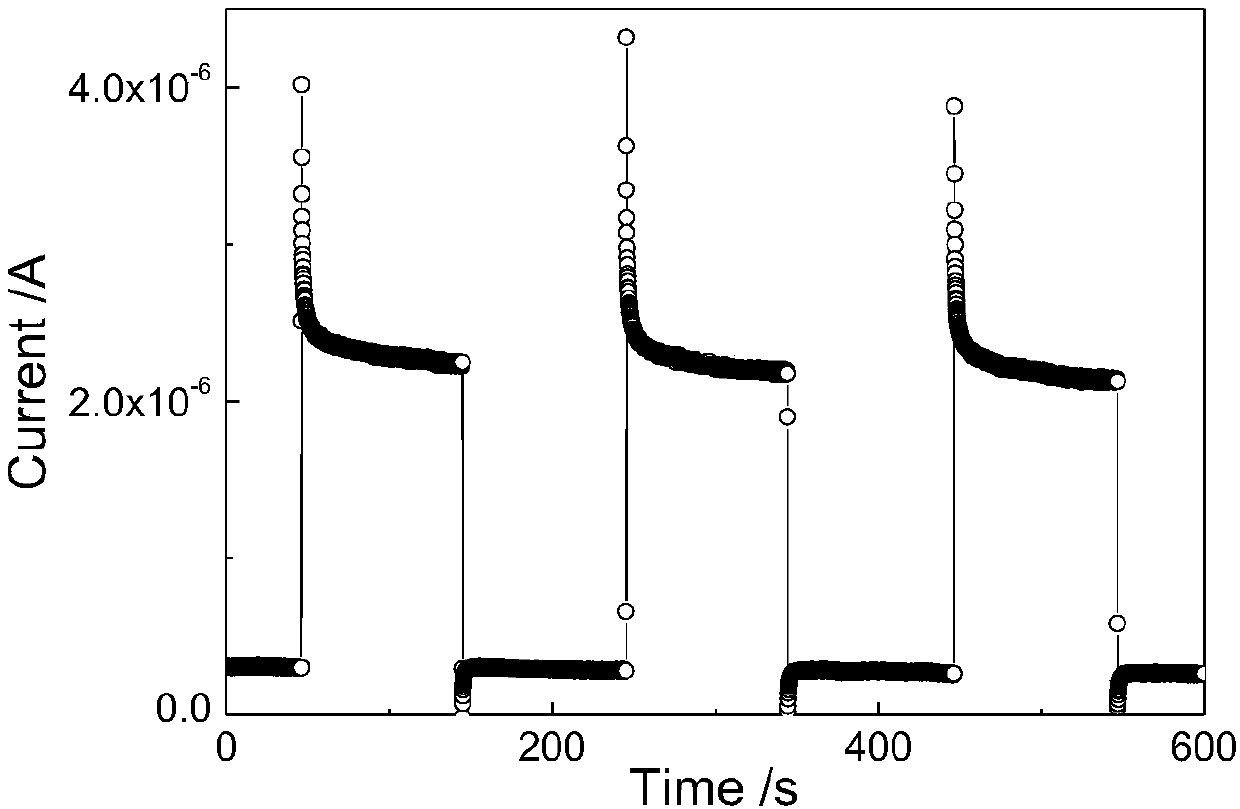

[0040] Drop 0.5 ml of graphene quantum dot dispersion liquid on the sample surface each time, let it stand for 5 minutes, wait for the dispersion liquid to infiltrate the sample, and then use the spin coating technology to evenly coat the dispersion liquid on the sample surface, and the spin coating rotation speed is 1000 revolutions / min, the coating time was 5 seconds, and then the sample was dried in the atmosphere at 100°C, and the above process was repeated 12 times to obtain graphene quantum dot-loaded Ag-TiO 2 Nanoarrays; samples also formed graphene quantum dots supported on Ag-TiO 2 Nanoarray composite nanomaterials, Ag-TiO modified by 12 graphene quantum dots 2 The number of graphene quantum dots on the nano-array is significantly increased, and the UV-visible absorption spectrum test results of the sample show that, compared with the sample obtained in Ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com