Organic solar cell with dynamically regulated transparency and preparation method and application thereof

A technology of solar cells and transparency, which is applied in the fields of renewable energy integration, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., and can solve the problem that the transparent color can no longer be adjusted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

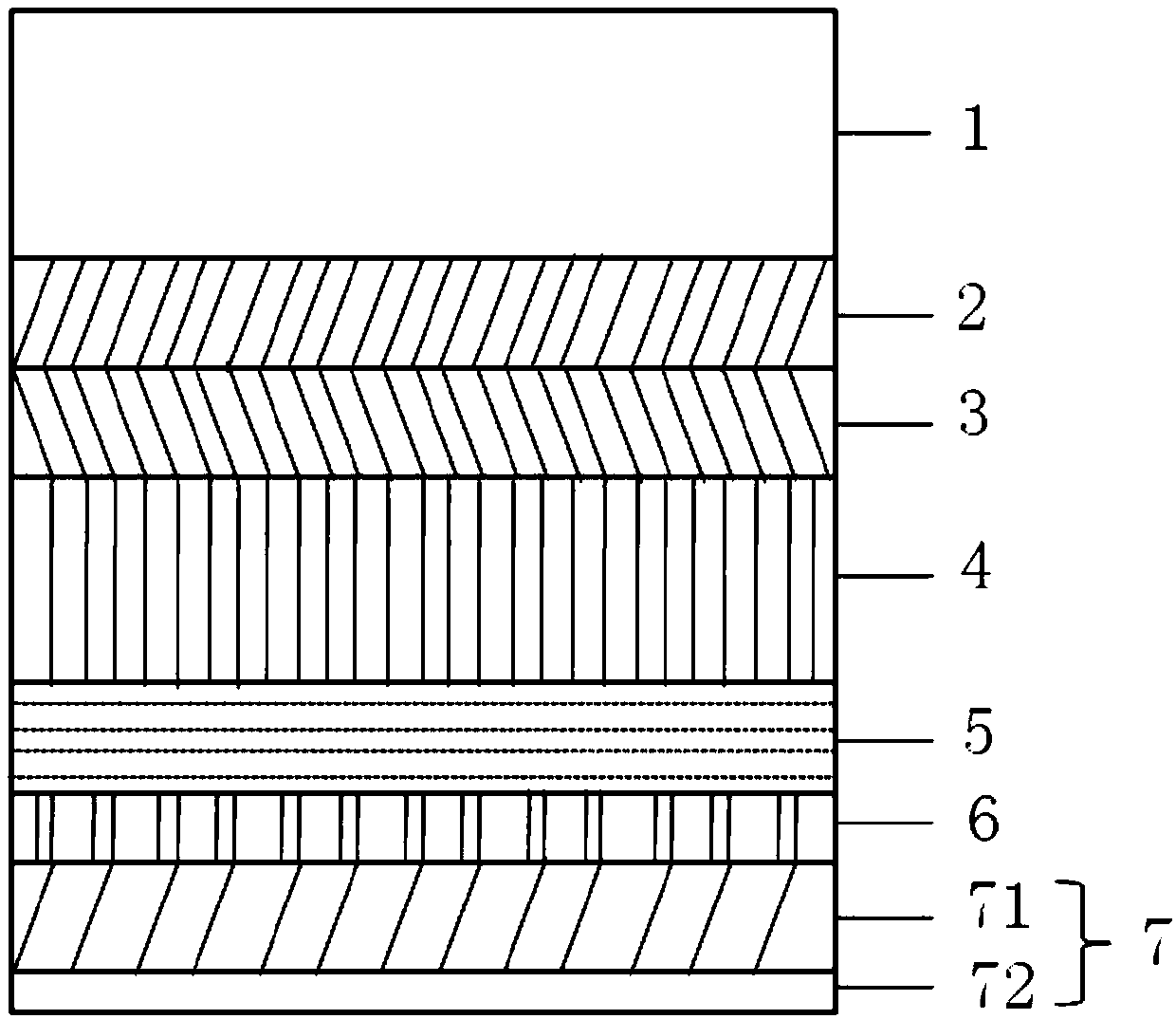

[0033] 1. Preparation:

[0034](1) Use glass as the substrate, wash it with deionized water, alcohol, acetone and other solutions for many times, and then treat it with oxygen plasma to make the first electrode ITO;

[0035] (2) Spin-coat the acetic acid solution of the PFN interface material with a concentration of 2mg / mL on the ITO electrode to make the first transport layer of PFN;

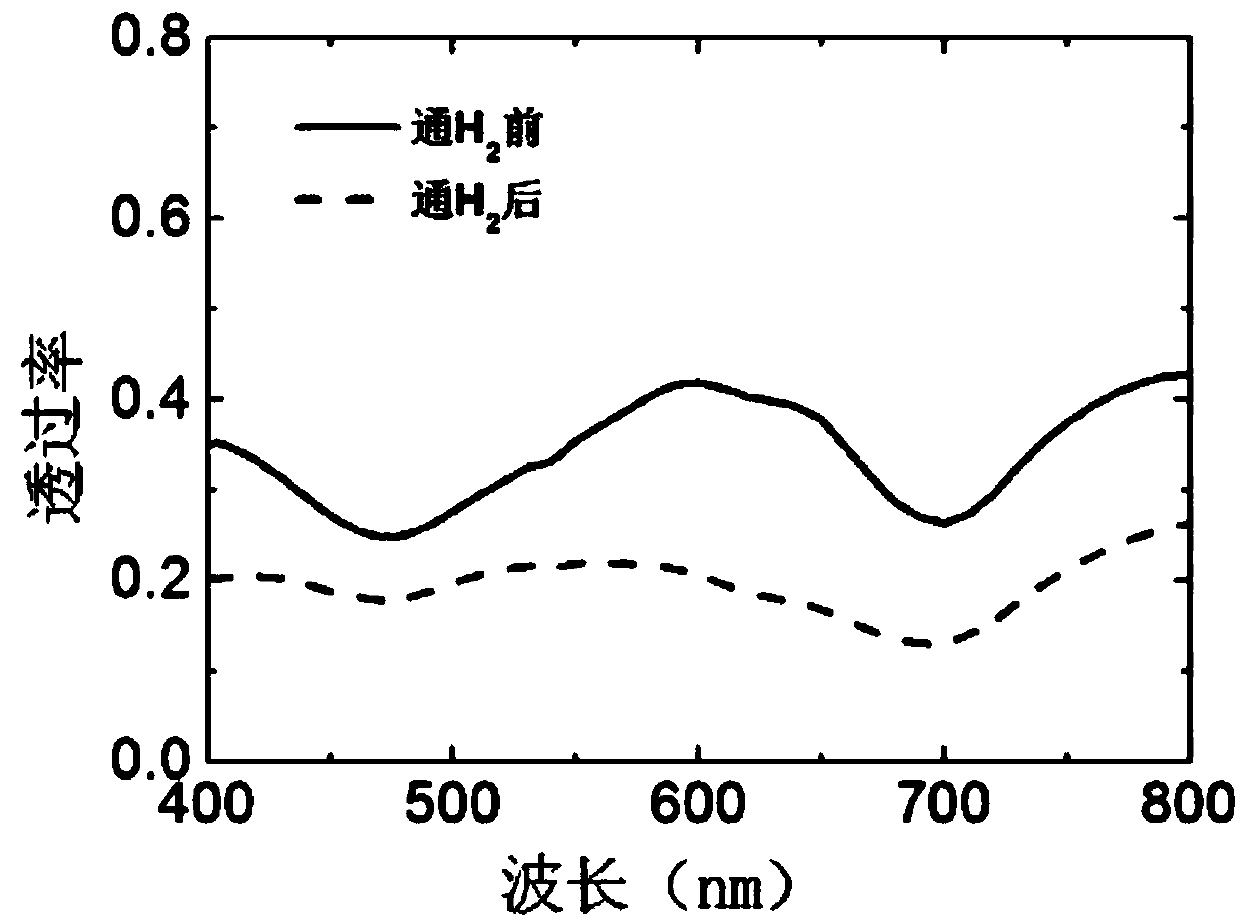

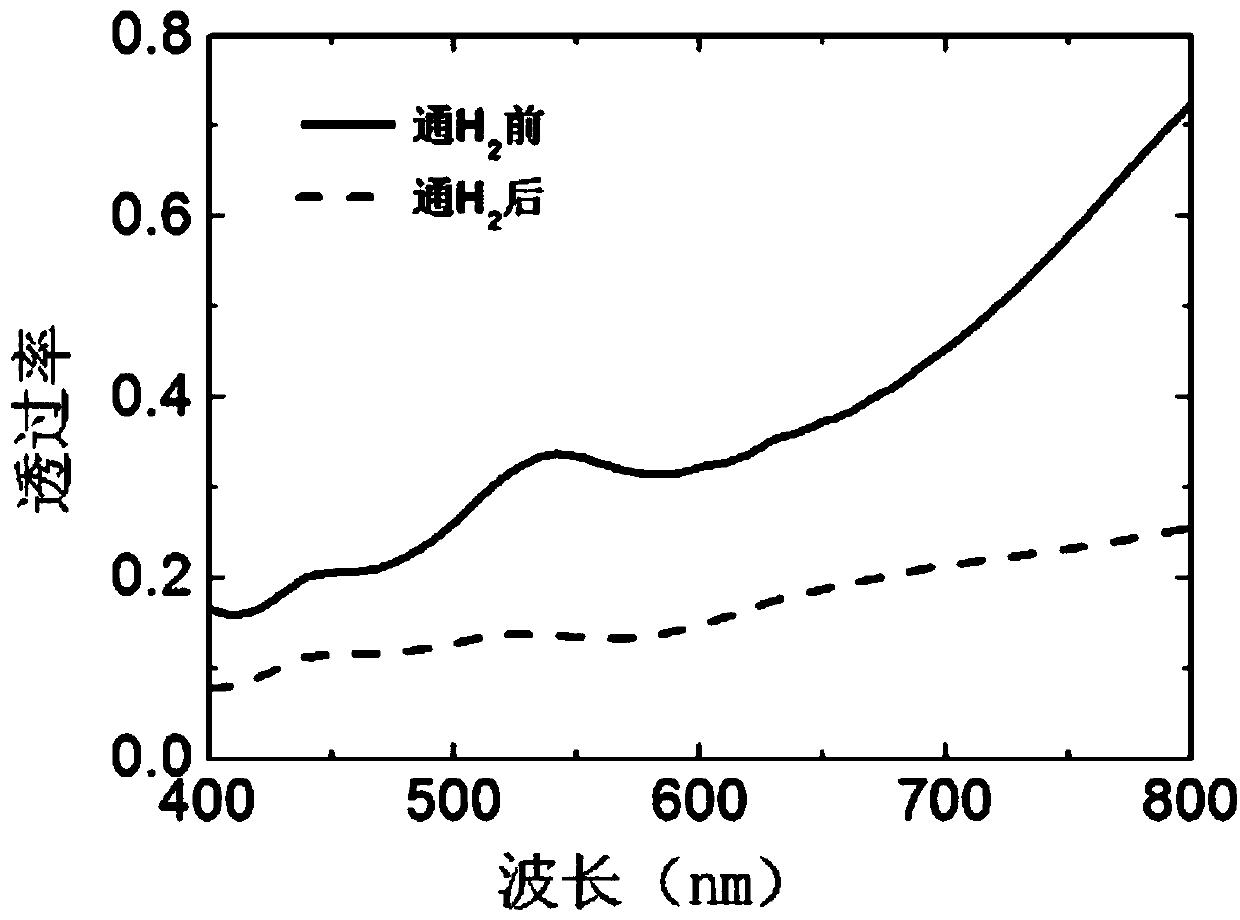

[0036] (3) Spin-coating PTB7 and PC 71 BM (or PTB7: PC 71 BM) mixed solution is spin-coated on PFN to form a photoactive layer, and the thickness of the photoactive layer is controlled by adjusting the spin-coating speed, thereby controlling the photoelectric conversion efficiency and transparency of the organic solar cell.

[0037] (4) Evaporate the second transport layer MoO on the surface of the photoactive layer by vacuum thermal method 3 , whose thickness is 10nm, then the MoO 3 Ag is vapor-deposited on the surface with a thickness of 15nm to make the second electrode Ag;

[0038] (5)...

Embodiment 2

[0048] 1. Preparation:

[0049] (1) Take polyethylene terephthalate (PET) as the base, use deionized water, alcohol, acetone and other solutions to wash it multiple times, and transfer the first electrode graphene to the PET;

[0050] (2) Spin-coat PEDOT:PSS on the graphene electrode to make the first transport layer with a thickness of 30nm-50nm;

[0051] (3) PCDTBT: PC was coated by spin coating method 71 The BM mixed solution was spin-coated on PEDOT:PSS to form a photoactive layer, and the thickness of the photoactive layer was controlled by adjusting the spin-coating speed, thereby controlling the photoelectric conversion efficiency and transparency of the battery device.

[0052] (4) Preparation of TiO by sol-gel method 2 , the TiO 2 spin-coated on the surface of the photoactive layer, and then on the TiO 2 Au is evaporated on the surface of the 15nm thickness to make the second electrode Au;

[0053] (5) Preparation of MoO on the surface of the second electrode Ag ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com