Method for manufacturing cutting-free lightweight-aggregate foamed cement insulation plate

A technology of foamed cement and manufacturing methods, applied in the field of building insulation materials, can solve problems such as air pollution, material loss, water pollution, etc., and achieve the effects of saving electricity costs, improving production efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

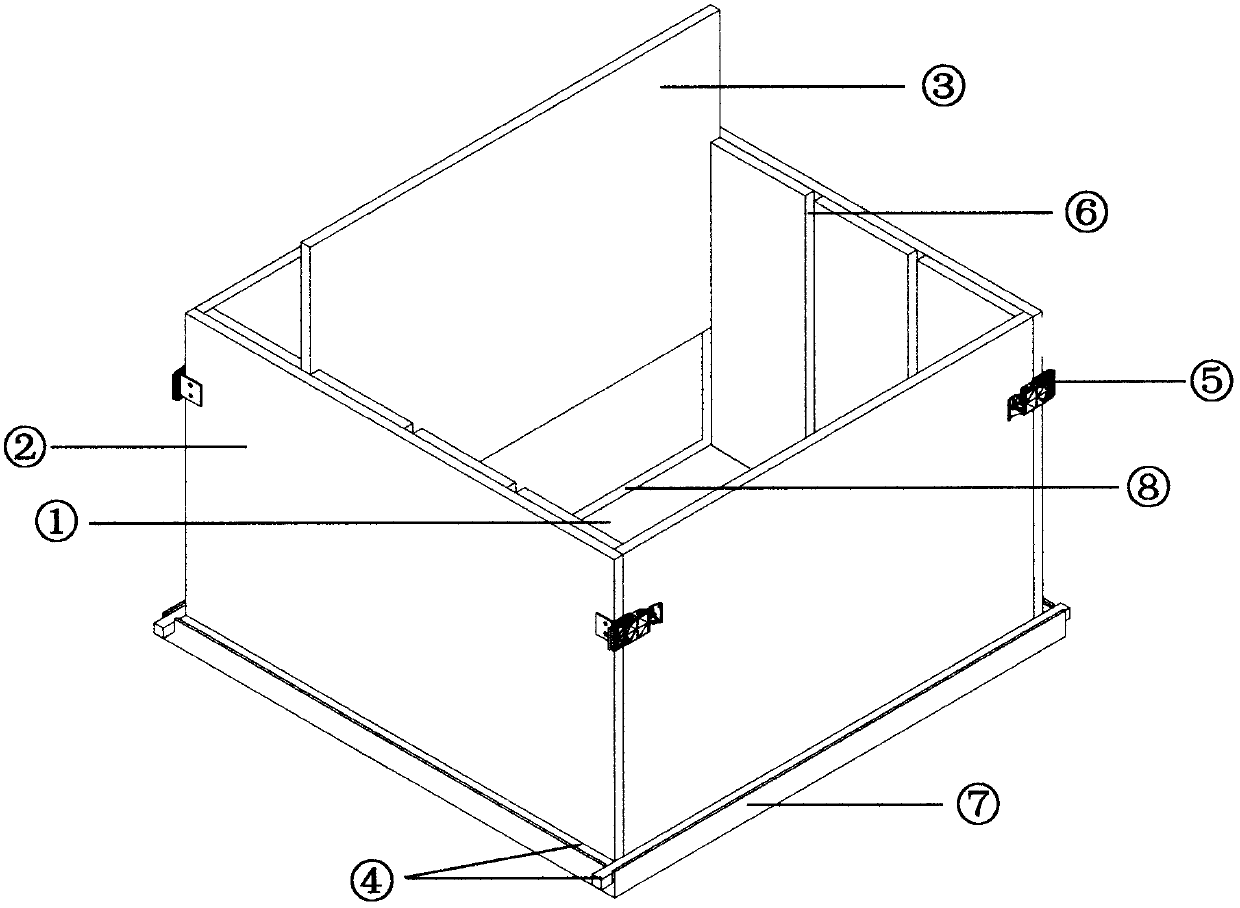

[0013] Put water, sodium rosinate, water-soluble polyvinyl alcohol powder, naphthalene-based water reducer, calcium stearate, 12 mm long chopped polypropylene fiber, fly ash, and 42.5# ordinary Portland cement into the mixing tank in sequence, Stir at high speed with a high-speed dispersing mixer to make foamed cement slurry; pump the foamed cement slurry to the ribbon mixer, and put in recycled particles of waste polystyrene foam while stirring; pour the mixed material into the combination In the mold, flatten it; after it solidifies, take out the fastening square tube, unlock the lock, take off the four side panels, and then take out the insulation board and partition in turn; clean the mold, apply the release agent, and reassemble it for later use; The demoulded insulation boards can be stacked in the curing area for curing.

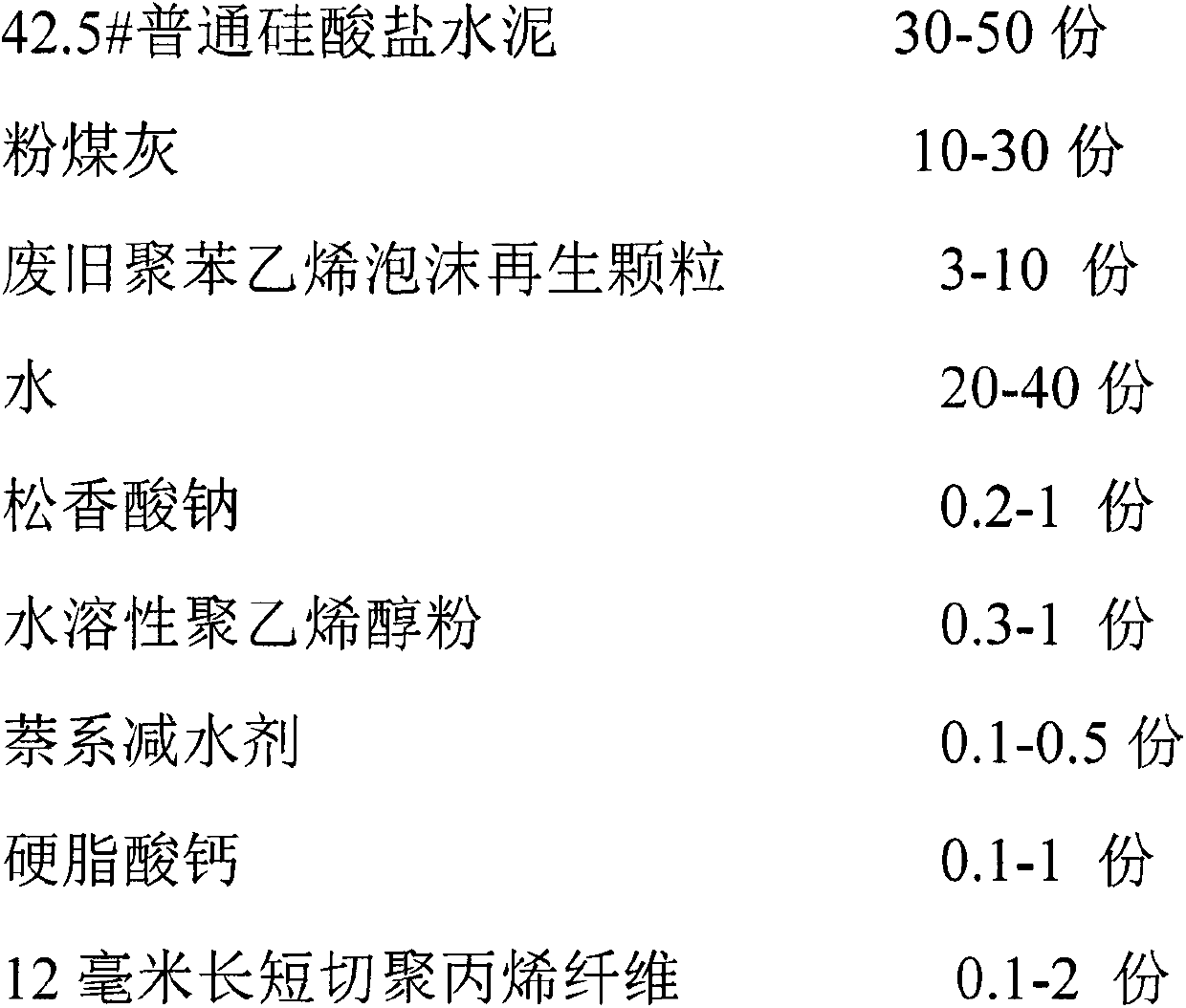

[0014] Embodiment 1 The weight ratio of each component of lightweight aggregate foamed cement mixture is as follows:

[0015]

Embodiment 2

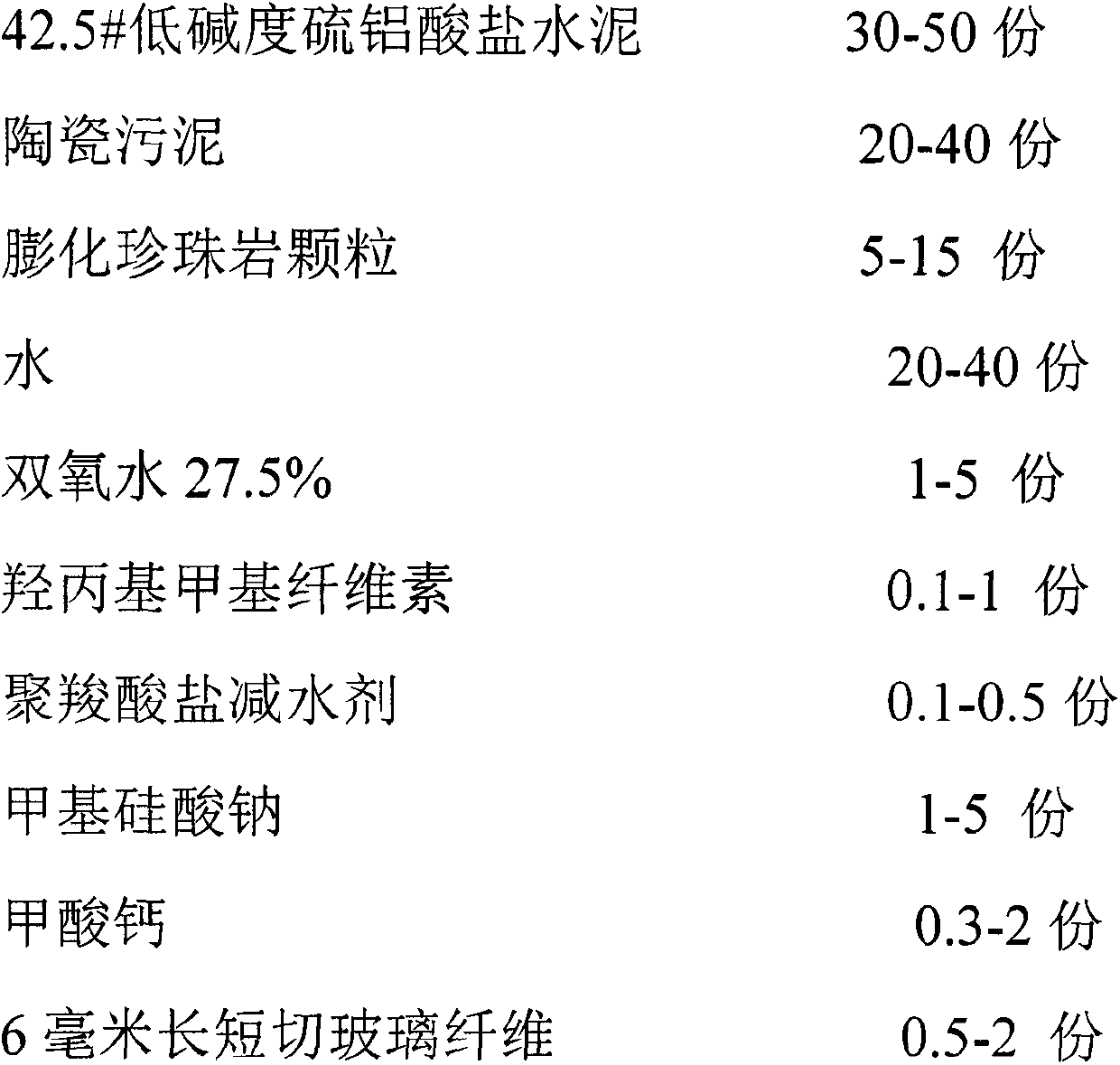

[0017] Water, hydrogen peroxide, hydroxypropyl methylcellulose, polycarboxylate superplasticizer, sodium methyl silicate, calcium formate, 6 mm long chopped glass fiber, ceramic sludge, 42.5# low alkalinity sulfoaluminate The cement is put into the mixing tank one by one, stirred at high speed with a high-speed dispersing mixer to make foamed cement slurry; the foamed cement slurry is transported to the ribbon mixer, and the expanded perlite particles are added while stirring; the mixed material is poured Put it into the combination mold and flatten it; after it solidifies, take out the fastening square tube, unlock the lock, take off the four side panels, and then take out the insulation board and partition board in turn; clean the mold, apply the release agent, and reassemble the equipment Use; the demoulded insulation boards can be stacked in the curing area for curing.

[0018] Example 2 The weight ratio of each component of the lightweight aggregate foamed cement mixture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com