Ethylene polymer catalyst with ultra-high molecular weight, and preparation method and application of catalyst

A technology of ethylene polymerization and catalyst, which is applied in the field of ultra-high molecular weight ethylene polymer catalyst and its preparation, and can solve problems such as unsatisfactory ethylene polymerization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

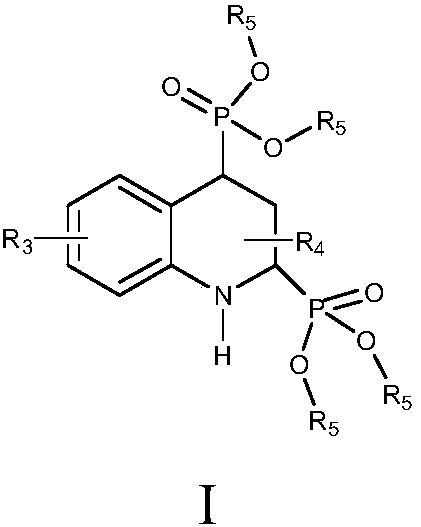

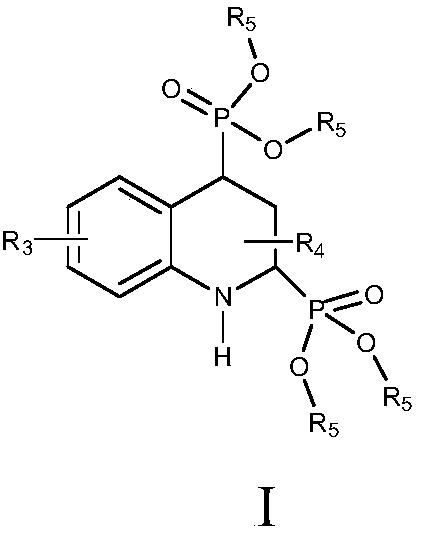

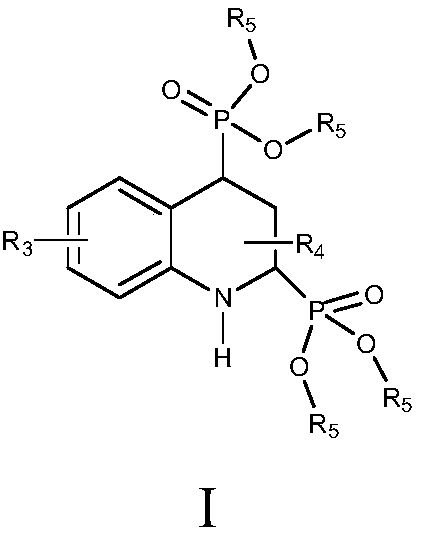

Image

Examples

Embodiment 1

[0071] Add 2 grams of magnesium ethoxide, 4 ml octanol and 15 ml n-heptane in a reactor protected by inert gas, add 0.03 mol of tetramethyl (1,2,3,4-tetrahydroquinoline-2, 4-disubstituted) bisphosphonate, after heating to reflux for 2 hours, cool the system to -25°C, slowly add 20ml of titanium tetrachloride and stir for 1 hour, then add 0.4g of diisophthalic acid after heating up to 60°C Butyl ester reacted for 2 hours, filtered off the supernatant, then added 25ml of titanium tetrachloride and ethyl titanate (volume ratio = 1:1) mixed solution, raised the temperature to 110°C for 2 hours, filtered, washed, and vacuum dried to obtain The solid catalyst is designated as Catalyst 1.

Embodiment 2

[0073] With reference to the method of Example 1, the catalysts of Example 2 can be prepared according to the ratio of raw materials in Table 1 below, which are respectively denoted as Catalyst 2, Catalyst 3, Catalyst 4, Catalyst 5, Catalyst 6, Catalyst 7 and Catalyst 8.

Embodiment 3

[0076] Embodiment 3 Polymerization activity test

[0077]Catalysts prepared in Examples 1, 2 and Comparative Example 1 were used to test the catalytic activity. Replace the 10L polymerization reactor with nitrogen, add 5000ml of hexane, 0.01mol of triethylaluminum, 30 mg of the catalyst prepared in Example 1, 2 and Comparative Example 1, control the pressure at 1.0MPa, feed ethylene, and control the polymerization temperature at 60 ℃~75℃, polymerized for 2 hours, vented the gas in the reactor, lowered to normal pressure, removed the solvent, and obtained the ultra-high molecular weight polyethylene product. The polymerization results are listed in Table 1:

[0078] Table 1

[0079]

[0080] As can be seen from the results in Table 1, catalyst 1-8 has higher catalytic activity than catalyst 1-3 of comparative example, and the obtained polymer has a high bulk density and higher molecular weight than the product obtained by catalytic polymerization of catalyst 1-3 of comparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com