A kind of ultra-high molecular weight ethylene polymer catalyst and its preparation method and application

A technology of ethylene polymerization and catalyst, which is applied in the field of ultra-high molecular weight ethylene polymer catalyst and its preparation, and can solve problems such as unsatisfactory ethylene polymerization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

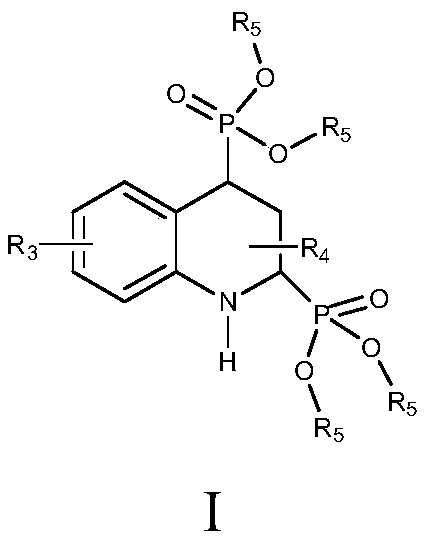

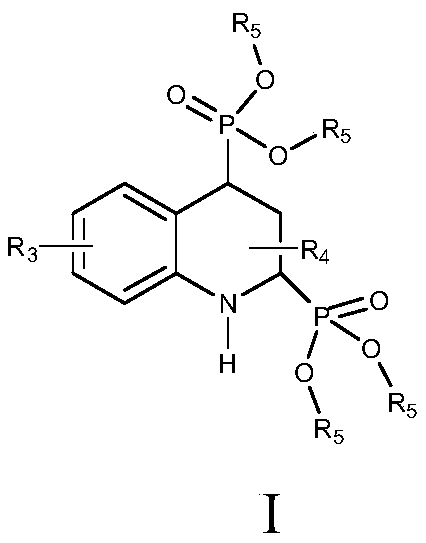

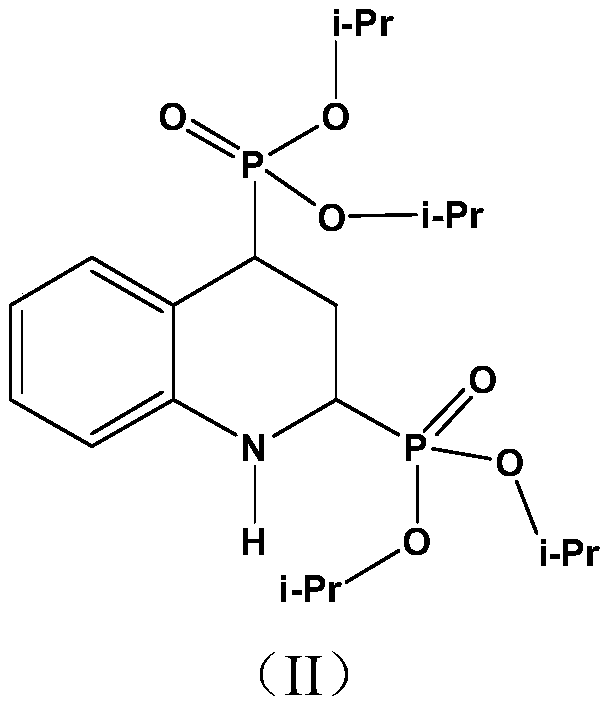

Image

Examples

Embodiment 1

[0071] Add 2 grams of magnesium ethoxide, 4ml of octanol and 15ml of n-heptane into a reactor protected by inert gas, and add 0.03mol of tetramethyl (1,2,3,4-tetrahydroquinoline-2, 4-Disubstituted) bisphosphate, after heating and refluxing for 2 hours, cool the system to -25°C, slowly add 20ml of titanium tetrachloride and stir for 1 hour, then add 0.4g of diisophthalic acid after heating to 60°C The butyl ester was reacted for 2 hours, the supernatant was filtered off, and 25ml of a mixed solution of titanium tetrachloride and ethyl titanate (volume ratio = 1:1) was added. The temperature was raised to 110°C and reacted for 2 hours, filtered, washed, and vacuum dried. The solid catalyst is referred to as catalyst 1.

Embodiment 2

[0073] With reference to the method of Example 1, the catalyst of Example 2 can be prepared according to the raw material ratio in Table 1 below, which are denoted as Catalyst 2, Catalyst 3, Catalyst 4, Catalyst 5, Catalyst 6, Catalyst 7, and Catalyst 8.

Embodiment 3

[0076] Example 3 Polymerization activity test

[0077] The catalysts prepared in the above Examples 1 and 2 and Comparative Example 1 were used for the catalytic reaction activity test. Replace the 10L polymerization reactor with nitrogen, add 5000ml of hexane, 0.01mol of triethylaluminum, 30 mg of the catalyst prepared in Examples 1, 2 and Comparative Example 1, control the pressure at 1.0MPa, feed ethylene, and control the polymerization temperature at 60 ℃~75℃, polymerize for 2 hours, vent the gas in the reactor, reduce to normal pressure, remove the solvent, and obtain ultra-high molecular weight polyethylene product. The polymerization results are listed in Table 1:

[0078] Table 1

[0079]

[0080] It can be seen from the results in Table 1 that, compared with the comparative catalysts 1-3, the catalysts 1-8 have higher catalytic activity, the obtained polymer has a higher bulk density, and the molecular weight is also higher than the product obtained by the catalytic polymer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com