Halogen-free composite flame retardant for thermoplastic elastomer and application thereof

A technology of thermoplastic elastomers and composite flame retardants, applied in the preparation of flame-retardant thermoplastic elastomers, in the field of halogen-free composite flame retardants for thermoplastic elastomers, can solve the problems of low flame retardant efficiency, large addition amount, and easy precipitation And other problems, to achieve good compatibility, good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

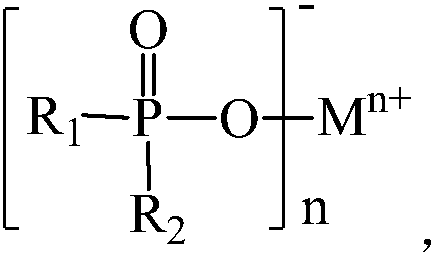

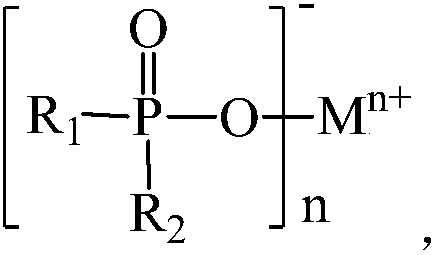

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of halogen-free composite flame retardant

[0029] 25 parts of aluminum diethylphosphinate, 5 parts of ammonium polyphosphate, 5 parts of H-beta molecular sieve, 30 parts of organically modified montmorillonite (magnesium-based montmorillonite), 35 parts of MCA.

[0030] Accurately weigh the above-mentioned components, and then fully mix the above-mentioned flame retardants by means of mechanical blending to obtain a halogen-free composite flame retardant.

[0031] (2) Application of composite flame retardant system in thermoplastic elastomer

[0032] a. Halogen-free flame retardant thermoplastic elastomer TPE system mixing

[0033] Add pre-weighed SEBS (25%) into the high-speed mixer, start stirring at a low speed, use a metering pump to inhale 18% white oil according to the proportion, mix thoroughly for 30 minutes, and keep the mixing temperature at 50°C to ensure that the white oil is fully absorbed by SEBS Absorb to complete the oil-filling proces...

Embodiment 2

[0040] The implementation process is the same as in Example 1, and the halogen-free composite flame retardant is as follows:

[0041] 23 parts of aluminum diethylphosphinate, 10 parts of zinc diethylphosphinate, 2 parts of ammonium polyphosphate, 5 parts of HZSM-5 modified molecular sieve, 20 parts of organically modified montmorillonite (calcium-based montmorillonite) , MCA40 copies.

[0042] The halogen-free composite flame retardant sample was treated by adding 2% of the total weight of the material to aluminum stearate for surface treatment, heated to 80°C, and stirred at high speed for 30 minutes to obtain a halogen-free composite flame retardant system. The proportions of each material and application results in the examples are shown in Table 1.

Embodiment 3

[0044] The implementation process is the same as in Example 1, and the halogen-free composite flame retardant is as follows:

[0045] 35 parts of aluminum diethylphosphinate, 1 part of ammonium polyphosphate, 2 parts of HZSM-5 modified molecular sieve, 27 parts of organically modified montmorillonite (magnesium-based montmorillonite), 35 parts of MPP.

[0046] Add 5% maleic anhydride graft compatibilizer POE to the halogen-free composite flame retardant sample for surface treatment, raise the temperature to 100°C, and stir at high speed for 30 minutes to obtain a halogen-free composite flame retardant system. The proportions of each material and application results in the examples are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com