Transparent hydrophobic wear-resistant coating and preparation method thereof

A wear-resistant coating and hydrophobic technology, applied in coatings, epoxy resin coatings, devices for coating liquids on the surface, etc., can solve problems such as high cost of nanoparticles, decreased light transmission performance of the coating surface, and complex equipment , to achieve the effects of large-scale industrial production, excellent interfacial interaction, and excellent scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

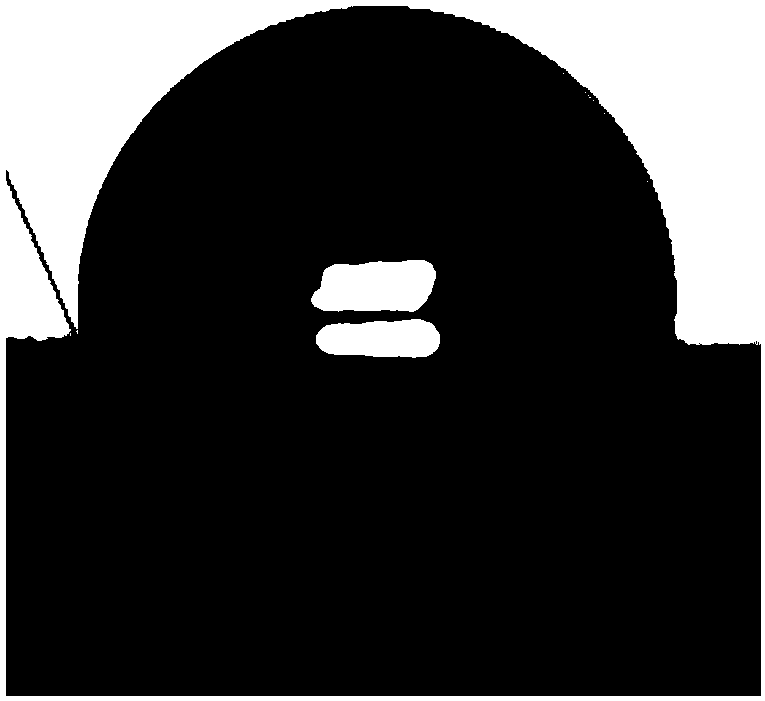

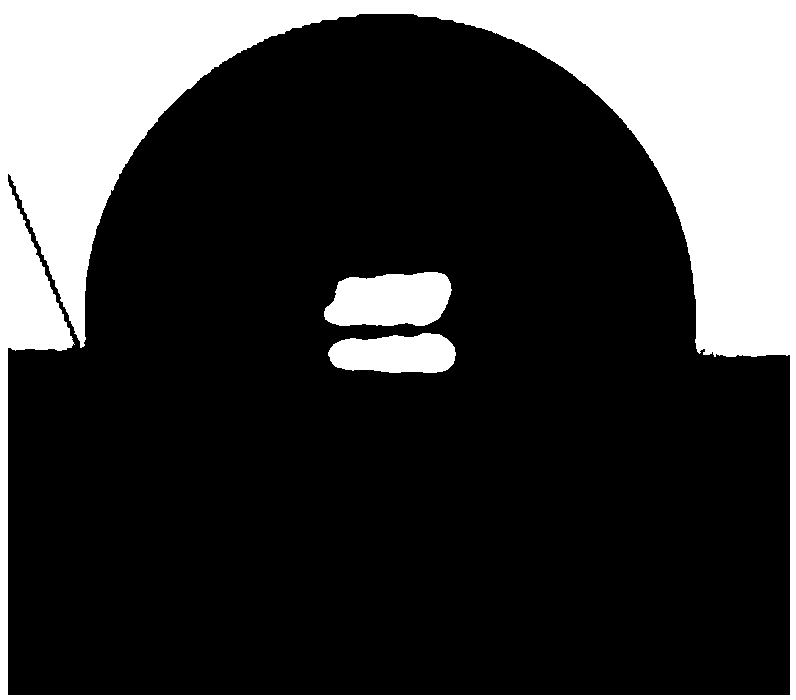

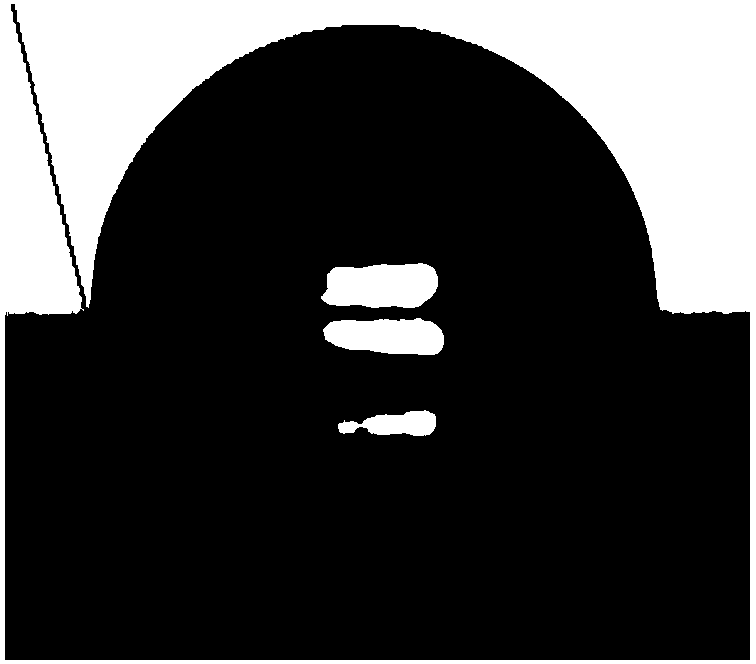

Image

Examples

Embodiment 1

[0048] A transparent hydrophobic wear-resistant coating comprises an epoxy resin layer and a low surface energy fluorine-containing layer arranged in sequence from top to bottom.

[0049] Its preparation steps are as follows:

[0050] 1) Preparation of epoxy resin coating:

[0051] Dissolve 2.63g of epoxy resin E-44 and 0.697g of polyetheramine D230 in 80mL of acetone, stir for 2h, and sonicate for 30min to obtain a transparent blend solution. Soak the glass slide (25*25*1mm) in the solution for 5s, pull it vertically at a speed of 6mm / s, place the base material containing the coating in a blast oven for heating and curing, and bake at 70°C Dry for 2 hours, and then dry at 120°C for 2 hours to obtain an epoxy resin coating with surface microscopic morphology.

[0052] 2) Preparation of low surface energy coating:

[0053] Add 2 μL of low surface energy substance dropwise to the surface of the substrate containing epoxy resin coating obtained in step 1), wipe the low surface...

Embodiment 2

[0056] A transparent hydrophobic wear-resistant coating comprises an epoxy resin layer and a low surface energy fluorine-containing layer arranged in sequence from top to bottom.

[0057] Its preparation steps are as follows:

[0058] 1) Preparation of epoxy resin coating:

[0059] Dissolve 1.16g of epoxy resin E-44 and 0.307g of polyetheramine D230 in 60mL of acetone, stir for 3h, and sonicate for 15min to obtain a transparent blend solution. Soak the glass slide (25*25*1mm) in the solution for 10s, pull it vertically at a speed of 4mm / s, place the obtained base material containing the coating in a blast oven for heating and curing, and bake at 70°C Dry for 2 hours, and then dry at 120°C for 2 hours to obtain an epoxy resin coating with surface microscopic morphology.

[0060] 2) Preparation of low surface energy coating:

[0061] Add 2 μL of low surface energy substance dropwise to the surface of the substrate containing epoxy resin coating obtained in step 1), wipe the l...

Embodiment 3

[0064] A transparent hydrophobic wear-resistant coating comprises an epoxy resin layer and a low surface energy fluorine-containing layer arranged in sequence from top to bottom.

[0065] Its preparation steps are as follows:

[0066] 1) Preparation of epoxy resin coating:

[0067] Dissolve 0.378g of epoxy resin E-44 and 0.1g of polyetheramine D230 in 60mL of acetone, stir for 1.5h, and sonicate for 30min to obtain a transparent blend solution. Soak the glass slide (25*25*1mm) in the solution for 12s, pull it vertically at a speed of 2mm / s, place the obtained base material containing the coating in a blast oven for heating and curing, and bake at 70°C Dry for 2 hours, and then dry at 120°C for 2 hours to obtain an epoxy resin coating with surface microscopic morphology.

[0068] 2) Preparation of low surface energy coating:

[0069] Add 2 μL of low surface energy substance dropwise to the surface of the substrate containing epoxy resin coating obtained in step 1), wipe the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com