Long-acting antifouling paint for ships and preparation method thereof

An antifouling coating, a technology for ships, applied in the field of coatings, can solve the problems affecting the aesthetics and reflectivity of ships, and poor antifouling properties of coatings, and achieve good aesthetics and reflectivity, and improve the effect of antifouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

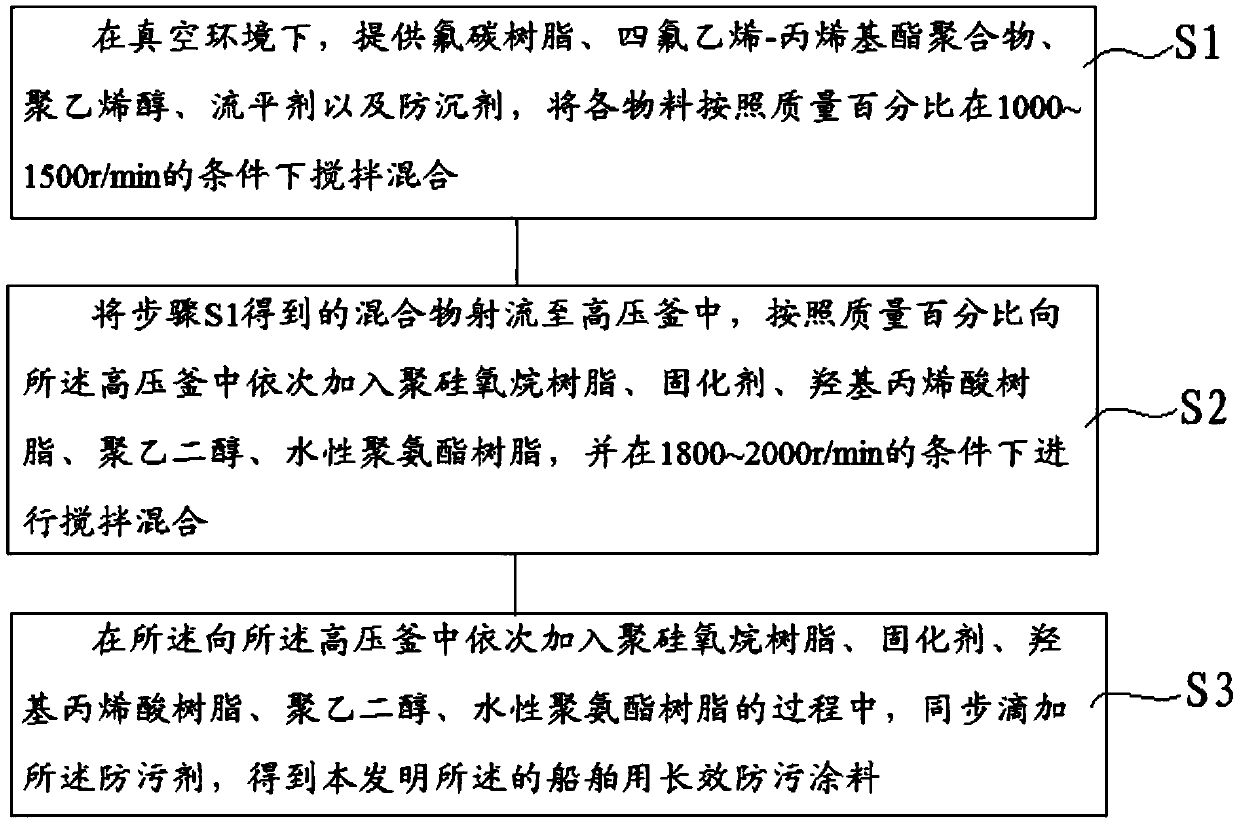

Method used

Image

Examples

Embodiment 1

[0034] Under a vacuum of -0.08MPa, provide 11% fluorocarbon resin, 15% tetrafluoroethylene-acryl ester polymer, 1.8% polyvinyl alcohol, 6% polyether polyester modified organosiloxane and polyamide wax 4%, each material was stirred and mixed according to the mass percentage under the condition of 1000r / min to obtain the mixture A. The mixture A was injected into the autoclave, and 26% of polysiloxane resin, 7.5% of vinyltriamine, 17% of hydroxyl acrylic resin, 13% of polyethylene glycol, polyester Type polyurethane 17%, and stir and mix under the condition of 1800. In the process of sequentially adding polysiloxane resin, curing agent, hydroxyacrylic resin, polyethylene glycol, and water-based polyurethane resin into the autoclave, sodium benzoate and polyacrylic acid were synchronously added dropwise at a speed of 12mL / min. The antifouling agent formed obtains the long-acting antifouling paint for ships of the present invention.

Embodiment 2

[0036]Under a vacuum of -0.10MPa, provide 11% fluorocarbon resin, 15% tetrafluoroethylene-acryl ester polymer, 1.8% polyvinyl alcohol, 6% polyether polyester modified organosiloxane, polyamide wax 4%, high-hardness oxide 6-8%, and chlorine-containing micropowder 3-8%, each material is stirred and mixed according to the mass percentage under the condition of 1200r / min, and the mixture B is obtained. The mixture B was injected into the autoclave, and 26% of polysiloxane resin, 7.5% of the mixture of ethylenetriamine and tetraethylenepentamine, 17% of hydroxyl acrylic resin, polyethylene 13% of diol and 17% of polycarbonate polyurethane were stirred and mixed under the condition of 2000°C. In the process of sequentially adding polysiloxane resin, curing agent, hydroxyacrylic acid resin, polyethylene glycol, and water-based polyurethane resin into the autoclave, sodium benzoate and polyacrylic acid were synchronously added dropwise at a speed of 15mL / min. The antifouling agent fo...

Embodiment 3

[0038] Under a vacuum of -0.10MPa, provide 11% fluorocarbon resin, 15% tetrafluoroethylene-acryl ester polymer, 1.8% polyvinyl alcohol, 6% polyether polyester modified organosiloxane, polyamide wax 4%, high-hardness oxide 6-8%, and chlorine-containing micropowder 3-8%, each material is stirred and mixed according to the mass percentage under the condition of 1200r / min, and the mixture C is obtained. The mixture C was injected into the autoclave, and 26% of polysiloxane resin, 7.5% of vinyl triamine, 17% of hydroxyl acrylic resin, 13% of polyethylene glycol, alkyl Alcohol amide 13%, monocrystalline silicon powder 8%, polyester polyurethane and polycarbonate polyurethane mixture 17%, and stirred and mixed under the condition of 1800°C. In the process of sequentially adding polysiloxane resin, curing agent, hydroxyacrylic resin, polyethylene glycol, and water-based polyurethane resin to the autoclave, cinnamon silicate sulfate is synchronously added dropwise at a speed of 15mL / mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com