Even-plating agent used for electroplating copper and relevant metal copper electroplating combination agent thereof

A technology for electroplating metal and copper electroplating, applied in the field of electroplating metal copper composition and electroplating additives, can solve the problems of uneven current density distribution, difficulty in making fine lines, uneven thickness of surface copper, etc., so as to reduce current efficiency and improve uniformity. The effect of improving the plating ability and improving the fineness of the line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

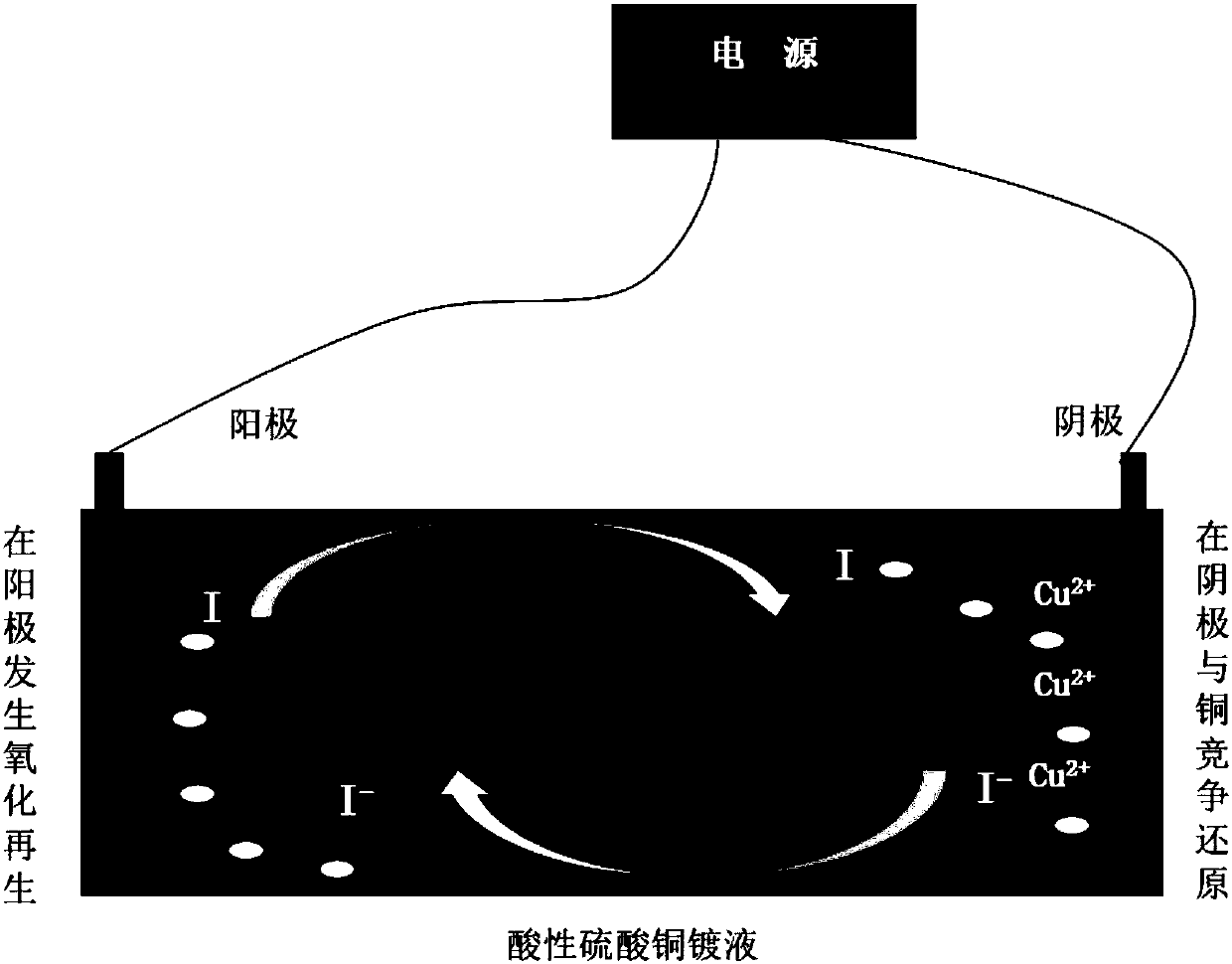

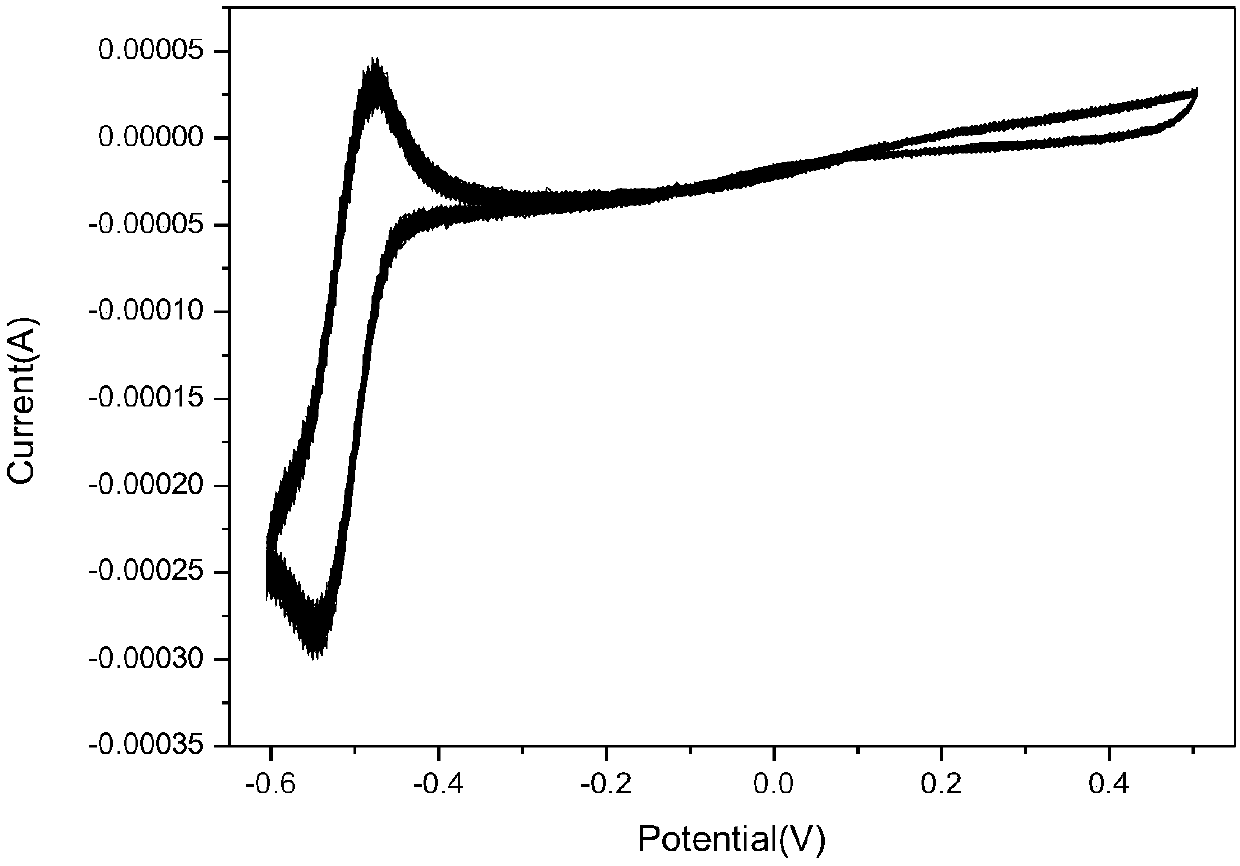

[0103] In this embodiment, 200mg / L benzoquinone and 10% copper sulfate are used to form a mixed solution system, and a three-electrode system is adopted, wherein the platinum electrode is used as the working electrode, the copper electrode is used as the counter electrode, and the mercuric sulfate electrode is used as the reference electrode; the scanning potential of the workstation is set to 0.5~-0.6V, the scan rate is 0.1V / S, the experiment scans 200 circles and finds that no peak attenuation occurs.

[0104] The standard electrode reduction potential of copper electrodeposition (that is, copper ions change to copper) is -0.342V, but considering the existence of overpotential and other influencing factors (such as electroplating additives, etc.) in the actual process, copper electrodeposition in acidic copper sulfate electroplating solution The potential range is -0.4~-0.78V vs. SSE. In this potential range, copper ions can obtain electrons at the cathode to become copper a...

Embodiment 2

[0106] In this embodiment, Hall cell electroplating is used to measure the effect of using the leveling agent provided by the present invention on the current efficiency.

[0107] This embodiment uses a current density of 4A / dm 2 , the electroplating time is 10min, the electroplating temperature is normal temperature, and the capacity of the Hall tank used for electroplating is 250mL; the plated piece is a 10cm×5cm brass sheet, and the brass sheet needs to be degreased, micro-etched, and pre-dipped before electroplating. , Washing treatment. The anodes used in electroplating are phosphor copper anodes. Table 1 shows the electroplating metal copper composition used in Hall cell electroplating and the calculated current efficiency.

[0108] The basic electroplating solution formula used in this embodiment is as follows:

[0109]

[0110] The calculation of current efficiency in the present embodiment is obtained according to Faraday's law M=k*I*t, wherein k is the electroc...

Embodiment 3

[0117] In this implementation, a Harlem cell is used to test the throwing ability of a double-sided printed circuit board with through holes electroplated with the plating formulation containing the throwing agent provided by the present invention.

[0118] The thickness of the test board used in this embodiment is 1.6 mm, and the diameter of the through hole is 250 μm. The test board is double-sided and its size is 10cm×5cm; the temperature of the plating solution is normal temperature, and the plating density is 2A / dm 2 , the electroplating time is 70min, and the stirring method is cathode bubbling; the capacity of the Harlem cell used for electroplating is 1.5L.

[0119] The basic electroplating formula used in this embodiment is the same as that of Example 1 as follows.

[0120] Before electroplating, the test board is subjected to acid degreasing and pre-dipping process to remove the surface contamination of the test board.

[0121] In this example, the electroplating a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com