Glue-dipping apparatus for honeycomb-shaped amphiphilic non-woven fabrics and process therefor

A dipping device and non-woven fabric technology, which is applied in lamination devices, textiles and papermaking, lamination, etc., can solve the problems of poor strength and durability, inability to clean, poor hydrophilicity, etc., achieve small vacuum resistance and save energy , low hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

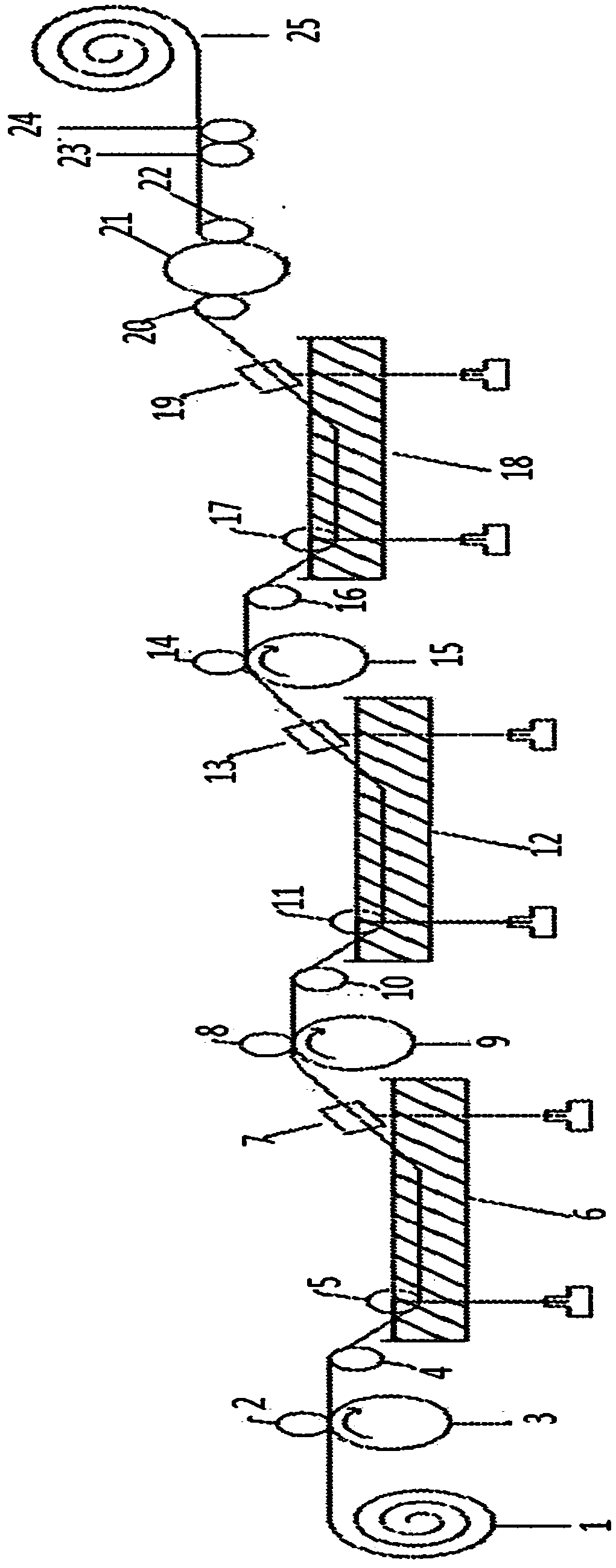

[0058] The present invention utilizes the dipping device of above-mentioned honeycomb amphiphilic non-woven fabric to carry out the technology of dipping, comprises the following steps:

[0059] 1) Place the non-woven fabric (the non-woven fabric of the present invention is a needle-punched felt non-woven fabric blended with nylon and polypropylene) on the first cloth roll retracting frame 1, and pass it through the first press roller 2, The first main roll 3 and the first guide roll 4 enter the first dipping tank 6 under the drafting of the first support roller 5 and dip in the first dipping bath with a temperature of 20°C to soak the nonwoven fabric. The surface of the cloth, so that the surface of the non-woven fabric is attached with a layer of surfactant, after dipping, the excess first bath dipping on the non-woven fabric is scraped back to the first dipping tank 6 by the first scraper 7;

[0060] 2) The non-woven fabric treated in step 1) passes through the second press...

Embodiment 2

[0083] Embodiment 2: The dipping process of honeycomb amphiphilic nonwoven fabric of the present invention is except following difference, all the other are with embodiment 1:

[0084] The first bath dipping consists of the following components in parts by weight: 490 parts of water, 10 parts of surfactants, wherein the surfactants are oleic acid, lauric acid, sodium laurate sulfate in a mass ratio of 1:2 : 3 mixed;

[0085] The deployment method of the first bath dipping is as follows:

[0086] (1) Add water into the reaction tank first, and control the water temperature at 30°C;

[0087] (2) Put the surfactant sodium lauryl sulfate into the reaction tank, stir for 25 minutes and mix well.

[0088]The second bath dipping glue consists of the following components in parts by weight: 600 parts of PVA glue, 150 parts of water, adhesive (adhesive is epoxy water-based adhesive, phenolic water-based adhesive, organic silicon water-based adhesive) Adhesive, rubber water-based adh...

Embodiment 3

[0104] Embodiment 3: The dipping process of honeycomb amphiphilic nonwoven fabric of the present invention is except following difference, all the other are with embodiment 1:

[0105] The first bath dipping consists of the following components in parts by weight: 470 parts of water, 30 parts of surfactants, wherein the surfactants are sodium dodecylsulfonate, sodium stearate, oleic acid, Lauric acid is mixed according to the mass ratio of 1:2:3:4;

[0106] The deployment method of the first bath dipping is as follows:

[0107] (1) Add water into the reaction tank first, and control the water temperature at 25°C;

[0108] (2) Put the surfactant sodium lauryl sulfate into the reaction tank, stir for 20 minutes and mix well.

[0109] The second bath dipping consists of the following components in parts by weight: 500 parts of PVA glue, 100 parts of water, adhesive (adhesive is water-based polyurethane adhesive, ethylene acetate water-based adhesive, ring Oxygen water-based ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com