Quaternary ammonium functionalized anion-exchange organic polymer monolithic column for capillary electrochromatography and its preparation and application

A technology of capillary electrochromatography and functionalization, which is applied in the field of quaternary ammonium functionalized anion-exchange organic polymer capillary electrochromatography monolithic columns, which can solve the problems of strong hydrophobicity, not widely used, difficult peak extraction, etc., and achieve good repeatability , good chromatographic performance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

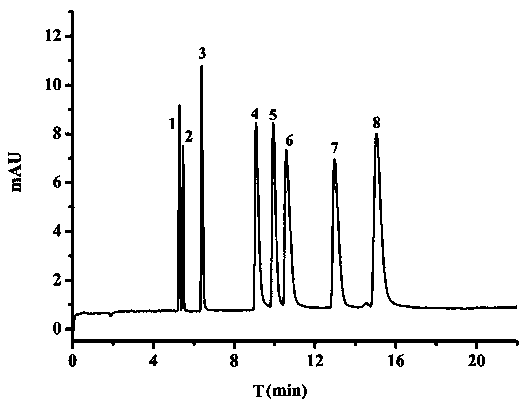

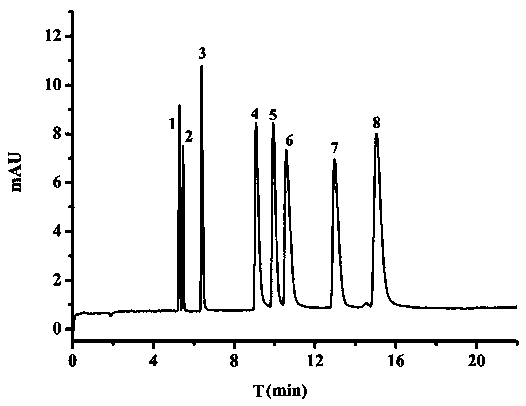

Image

Examples

Embodiment 1

[0020] (1) Cut off a 35cm long quartz capillary (inner diameter 100μm). After pretreatment, prepare a 50% (v / v) methanol solution of methacryloxypropyltrimethoxysilane, suck it into a syringe and inject it into the pretreated capillary, Connect the two ends with Teflon to form a ring, and place it in a 45°C water bath overnight to react to vinylize the inner wall of the capillary; then rinse the capillary with methanol for 30 minutes, and dry it with N 2 Blow dry and set aside.

[0021] (2) Mix 20 mg of N-benzylquinine chloride, 20 mg of methacrylamide, 76 μL of ethylene glycol dimethacrylate, 303 μL of methanol, 143 μL of diethylene glycol, and 2.0 mg of azo Diisobutyronitrile was placed in a 2mL eppendorf tube, and ultrasonically mixed for 10 minutes to remove air bubbles.

[0022] (3) Inject the homogeneous solution obtained in step (2) into the capillary treated with the silylating reagent in step (1), control the injection length to 25.5 cm, seal both ends with silica ge...

Embodiment 2

[0025] (1) Cut off a 35cm long quartz capillary (inner diameter 100μm). After pretreatment, prepare a 50% (v / v) methanol solution of methacryloxypropyltrimethoxysilane, suck it into a syringe and inject it into the pretreated capillary, Connect the two ends with Teflon to form a ring, and place it in a 45°C water bath overnight to react to vinylize the inner wall of the capillary; then rinse the capillary with methanol for 30 minutes, and dry it with N 2 Blow dry and set aside.

[0026] (2) Add 25 mg of N-benzylquinine chloride, 15 mg of methacrylamide, 76 μL of ethylene glycol dimethacrylate, 303 μL of methanol, 143 μL of diethylene glycol, and 2.0 mg of azo Diisobutyronitrile was placed in a 2mL eppendorf tube, and ultrasonically mixed for 10 minutes to remove air bubbles.

[0027] (3) Inject the homogeneous solution obtained in step (2) into the capillary treated with the silylating reagent in step (1), control the injection length to 25.5 cm, seal both ends with silica ge...

Embodiment 3

[0029] (1) Cut off a 35cm long quartz capillary (inner diameter 100μm). After pretreatment, prepare a 50% (v / v) methanol solution of methacryloxypropyltrimethoxysilane, suck it into a syringe and inject it into the pretreated capillary, Connect the two ends with Teflon to form a ring, and place it in a 45°C water bath overnight to react to vinylize the inner wall of the capillary; then rinse the capillary with methanol for 30 minutes, and dry it with N 2 Blow dry and set aside.

[0030] (2) Mix 30 mg of N-benzylquinine chloride, 10 mg of methacrylamide, 76 μL of ethylene glycol dimethacrylate, 303 μL of methanol, 143 μL of diethylene glycol, and 2.0 mg of azo Diisobutyronitrile was placed in a 2mL eppendorf tube, and ultrasonically mixed for 10 minutes to remove air bubbles.

[0031] (3) Inject the homogeneous solution obtained in step (2) into the capillary treated with the silylating reagent in step (1), control the injection length to 25.5 cm, seal both ends with silica ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com