Wear-resistant flame-retardant conveying belt

A technology for conveyor belts and mixtures, applied in the field of wear-resistant and flame-retardant conveyor belts, can solve the problems of poor flame-retardant and wear-resistant performance of conveyor belts, and achieve the effects of not easy delamination, low energy consumption, and improved overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

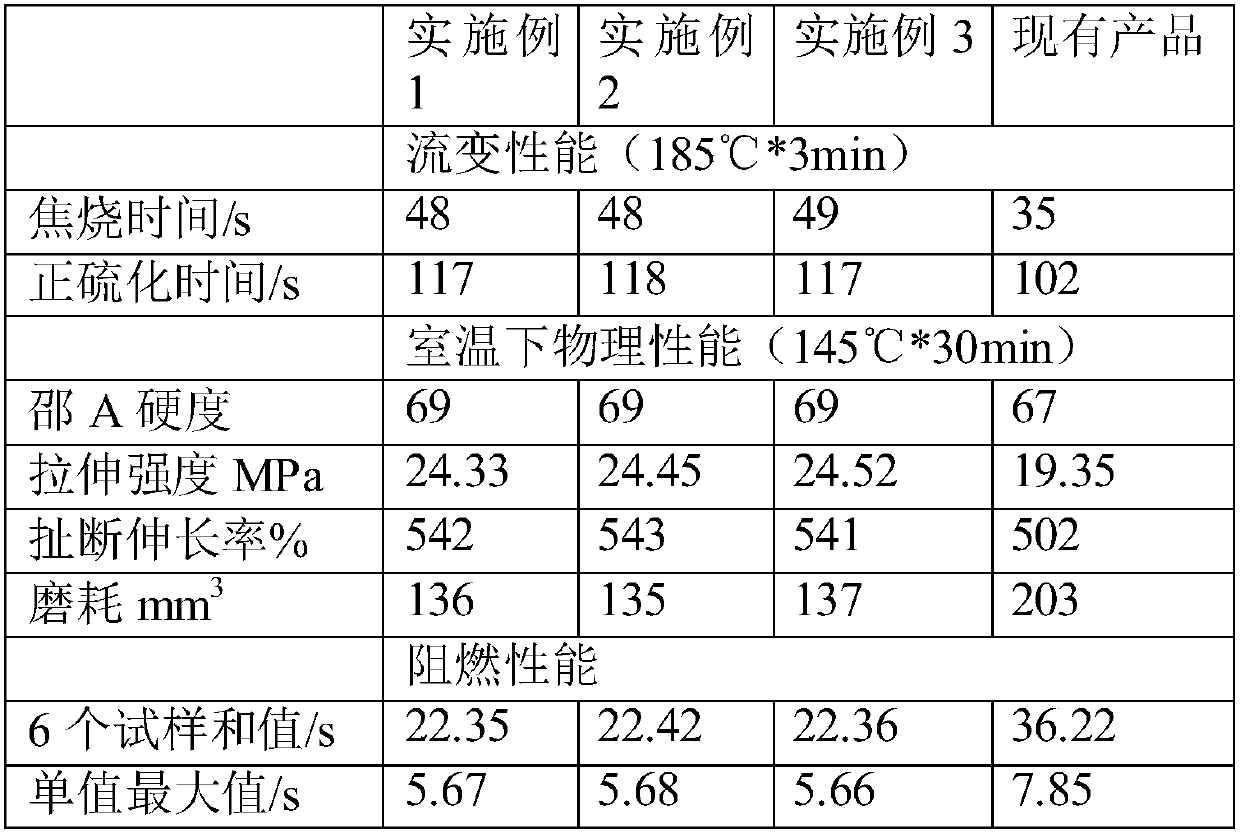

Examples

Embodiment 1

[0022] Wear-resistant and flame-retardant conveyor belt, the components of the raw materials are composed as follows in parts by weight:

[0023] 22 parts of EPDM rubber, 15 parts of neoprene rubber, 10 parts of nitrile rubber, 8 parts of chlorinated polyethylene, 4 parts of carbon black, 7 parts of sulfur, triisopropylphenyl phosphate, polyisocyanate and dichloro Propyl phosphate is composed of 3 parts of phosphorus-containing flame retardant in a weight ratio of 2:1:1, 0.6 parts of dibenzothiazole disulfide, ammonium polyphosphate, calcium carbonate and pine tar in a weight ratio of 2:2:5 1.2 parts of compound stabilizer, 0.8-1 part of N-isopropyl-N'-phenyl-p-phenylenediamine, 2 parts of anti-aging agent composed of 4010NA and RD according to the weight ratio of 2:3, lead stearate 0.5 parts of dispersant composed of chlorinated paraffin at a weight ratio of 1:3, 6 parts of adhesive composed of reclaimed rubber RR, cyclohexanone and toluene at a weight ratio of 7:2:2, 2 parts...

Embodiment 2

[0025] Wear-resistant and flame-retardant conveyor belt, the components of the raw materials are composed as follows in parts by weight:

[0026] 23 parts of EPDM rubber, 16 parts of neoprene rubber, 12 parts of nitrile rubber, 10 parts of chlorinated polyethylene, 5 parts of carbon black, 8 parts of sulfur, triisopropylphenyl phosphate, polyisocyanate and dichloro Propyl phosphate is composed of 4 parts of phosphorus-containing flame retardant in a weight ratio of 2:1:1, 0.7 parts of dibenzothiazole disulfide, ammonium polyphosphate, calcium carbonate and pine tar in a weight ratio of 2:2:5 1.4 parts of composite stabilizer, 0.8-1 part of N-isopropyl-N'-phenyl-p-phenylenediamine, 2.5 parts of anti-aging agent composed of 2:3 weight ratio of anti-aging agent 4010NA and anti-aging agent RD, lead stearate 0.6 parts of dispersant composed of chlorinated paraffin in a weight ratio of 1:3, 8 parts of adhesive composed of reclaimed rubber RR, cyclohexanone and toluene in a weight ra...

Embodiment 3

[0028] Wear-resistant and flame-retardant conveyor belt, the components of the raw materials are composed as follows in parts by weight:

[0029] 25 parts of EPDM rubber, 18 parts of neoprene rubber, 15 parts of nitrile rubber, 12 parts of chlorinated polyethylene, 6 parts of carbon black, 10 parts of sulfur, triisopropylphenyl phosphate, polyisocyanate and dichloro Propyl phosphate is composed of 5 parts of phosphorus-containing flame retardant in a weight ratio of 2:1:1, 0.8 parts of dibenzothiazole disulfide, ammonium polyphosphate, calcium carbonate and pine tar in a weight ratio of 2:2:5 1.5 parts of composite stabilizer, 1 part of N-isopropyl-N'-phenyl-p-phenylenediamine, 3 parts of anti-aging agent composed of 2:3 weight ratio of anti-aging agent 4010NA and anti-aging agent RD, lead stearate and chlorine 0.7 parts of dispersant composed of paraffin wax in a weight ratio of 1:3, 9 parts of adhesive composed of reclaimed rubber RR, cyclohexanone and toluene in a weight ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com