Preparation method and construction process for elastic waterproof roof paint

A waterproof coating and elastic technology, applied in anti-fouling/underwater coatings, anti-corrosion coatings, roofing, etc., can solve the problems of non-environmental protection of organic solvents, poor weather resistance, fear of scratches, etc., to achieve easy renovation, easy operation of production process, The effect of eliminating mechanical air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A preparation method of an elastic roof waterproof coating, comprising (1) a preparation method of a primer; (2) a preparation method of a topcoat; the primer includes A component and B component, and the primer B component It is a commercially available water-based composite resin.

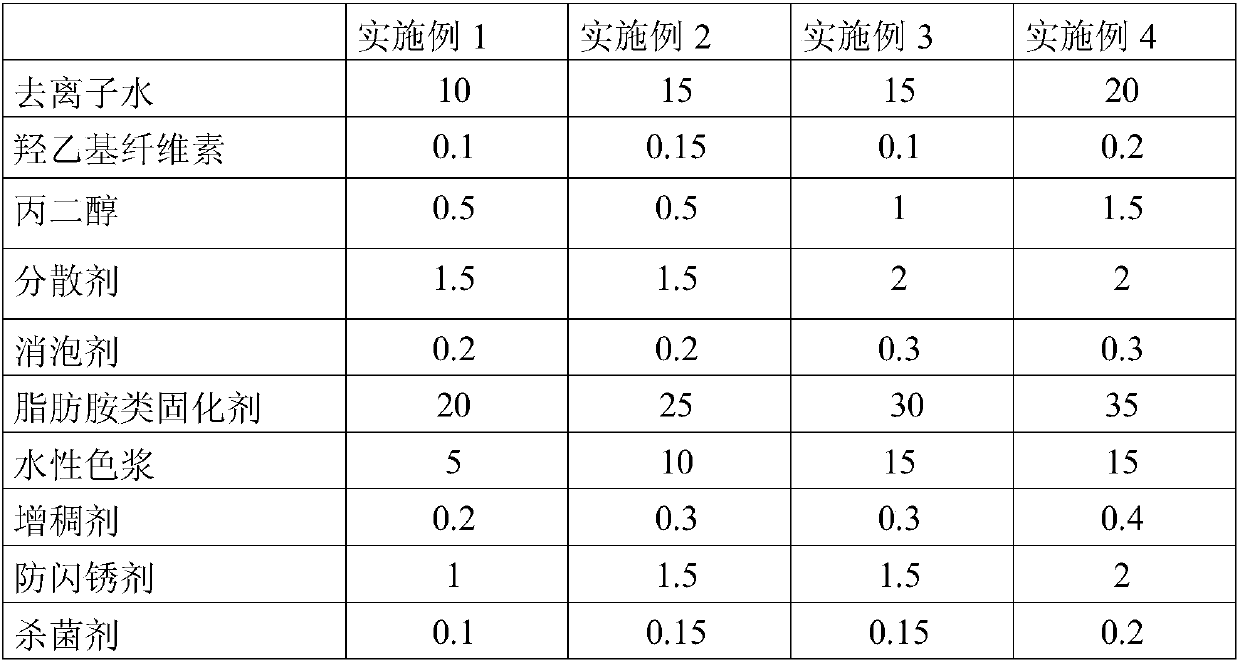

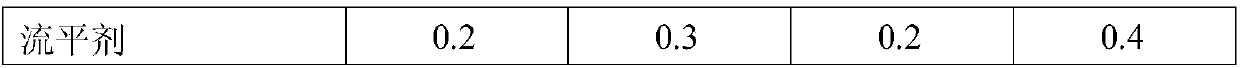

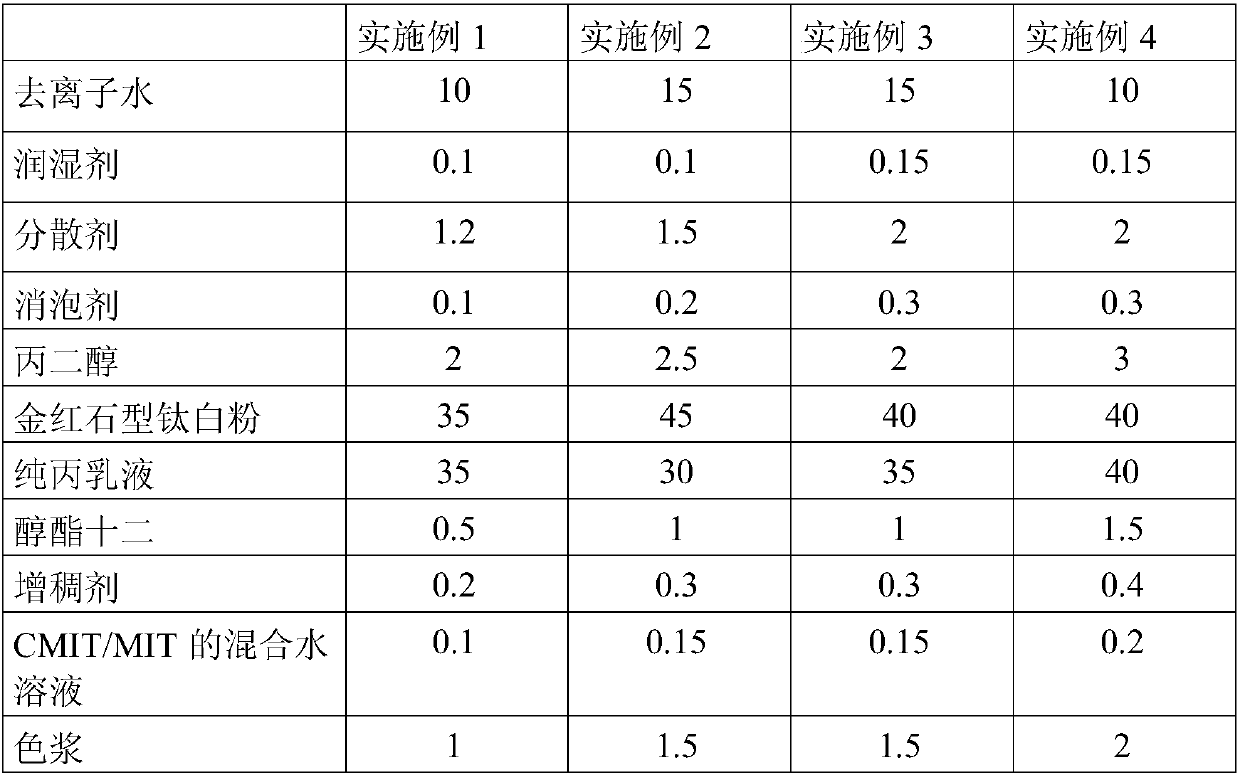

[0035] In embodiment 1-4, each raw material ratio is as follows in the primer A component preparation method following table (unit: Kg):

[0036]

[0037]

Embodiment 5

[0038] Embodiment 5: optimal embodiment in the preparation method of primer A component, the following components are calculated by weight ratio:

[0039] 1) Stir 20 parts of deionized water and 0.3 parts of hydroxyethyl cellulose at low speed for 10 minutes until completely dissolved;

[0040] 2) During the stirring process, add 30 parts of aliphatic amine curing agent, 0.5 part of propylene glycol, 0.3 part of wetting agent, 3 parts of dispersant, 45 parts of pigments and fillers, and disperse with high-speed stirring for 1 hour;

[0041] 3) Add 0.3 parts of defoamer, 3 parts of anti-flash rust agent, stir at medium speed for 20-30 minutes;

[0042] 4) Add 0.2 part of thickener, 0.3 part of leveling agent, 0.2 part of bactericide and stir at medium speed for 30 minutes;

[0043] 5) Stop stirring at a medium speed to disperse, and then obtain component A of the primer.

[0044] In the preparation method step (2) of the primer A component, the wetting agent is APEO-free and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com