Preparation method and application of arrayed carbon nanotube foam metal composite substrate

A carbon nanotube and metal foam technology, which is applied in metal material coating process, hybrid capacitor current collector, electrochemical generator, etc. Increases cyclic stability, facilitates release, maintains structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. Select foamed nickel with a porosity of 95% and a pore size of 6mm (thickness 1.4mm). Use 1M HCl to soak the foamed nickel substrate at room temperature for 1 hour to remove surface oxides. The size of the foamed nickel material is 0.5*3 cm 2 , after washing with deionized water, put it into a vacuum drying oven to dry for later use;

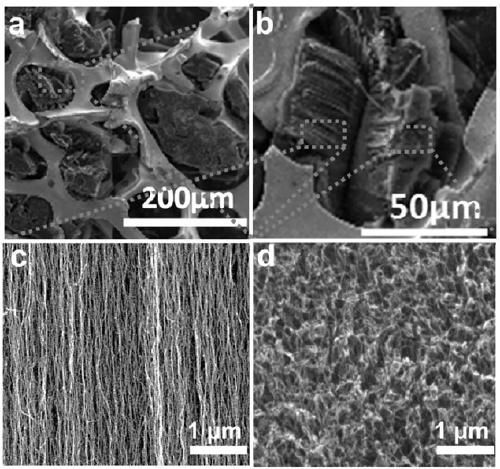

[0048] 2. Using Fe, Ni catalyst, CH 4 As the reaction gas, the reaction temperature was 700°C, and the reaction time was 20 minutes. The arrayed carbon nanotubes with a height of 2000 μm and a diameter of 20 nm were grown by chemical vapor deposition, and the arrayed carbon nanotubes were subjected to plasma etching at 18W for 20s in an oxygen atmosphere. Flow 200 mL / min;

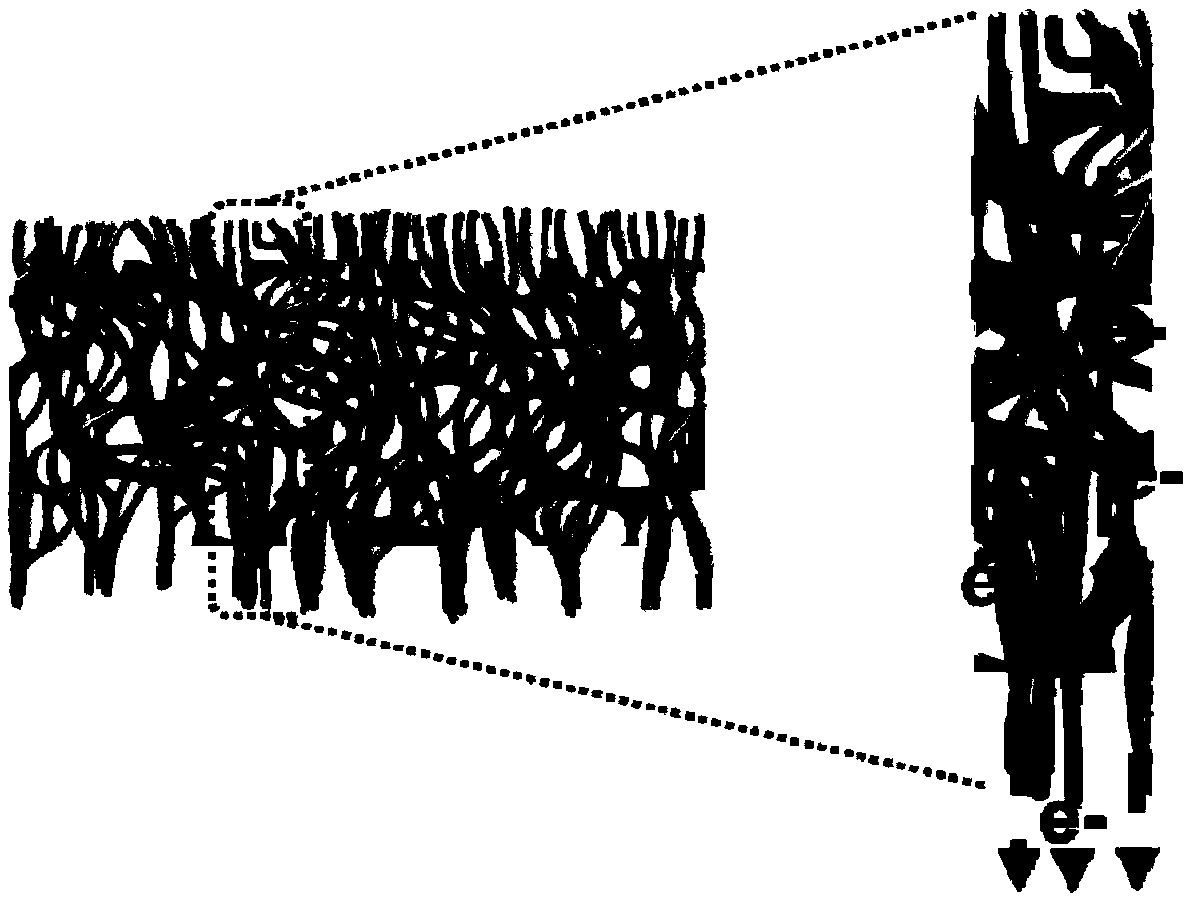

[0049] 3. Place the arrayed carbon nanotubes obtained in step 2 vertically above the nickel foam obtained after cleaning in step 1, place the two in the middle of the tablet press, and then perform 40MPa pressure treatment for 1min. Schematic diagram of the compos...

Embodiment 2

[0053] 1. Select foamed nickel with a porosity of 90% and a pore size of 0.2 mm (thickness 0.5 mm), use 1M HCl to soak the foamed nickel substrate at room temperature for 1 hour to remove surface oxides, and the size of the foamed nickel material is 0.5*3 cm 2 , after washing with deionized water, put it into a vacuum drying oven to dry for later use;

[0054] 2. Using Fe, Ni catalyst, CH 4 As the reaction gas, the reaction temperature was 700°C, and the reaction time was 12 minutes. The arrayed carbon nanotubes with a height of 800 μm and a diameter of 2 nm were grown by chemical vapor deposition, and the arrayed carbon nanotubes were etched with plasma at 50W for 20s in an air atmosphere. Gas flow rate 300 mL / min;

[0055] 3. Place the arrayed carbon nanotubes obtained in step 2 vertically above the nickel foam obtained after cleaning in step 1, place the two in the middle of the tablet press, and then perform a 1MPa pressure treatment for 1min to obtain an array composite ...

Embodiment 3

[0061] 1. Choose nickel foam with a porosity of 90% and a pore size of 0.15mm (thickness 0.1mm). Use 1M HCl to soak the nickel foam substrate at room temperature for 1 hour to remove surface oxides. The size of the nickel foam material is 0.5*3 cm 2 , after washing with deionized water, put it into a vacuum drying oven to dry for later use;

[0062] 2. Using Fe, Ni catalyst, CH 4 As the reaction gas, the reaction temperature was 700°C, and the reaction time was 5 minutes. The arrayed carbon nanotubes with a height of 150 μm and a diameter of 20 nm were grown by chemical vapor deposition, and the arrayed carbon nanotubes were plasma-etched for 1W 100s in an air atmosphere. Gas flow rate 100 mL / min;

[0063] 3. Place the arrayed carbon nanotubes obtained in step 2 vertically above the nickel foam obtained after cleaning in step 1, place the two in the middle of the tablet press, and then perform 10MPa pressure treatment for 1min.

[0064] 4. Using the platinum electrode as the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com