Process for preparing microcapsule by initiating active fine emulsion polymerization of water-soluble initiating agent

A water-soluble initiator, a technology of mini-emulsion polymerization, applied in the field of emulsion polymerization, can solve the problems of difficult to maintain stability of the dispersion system, poor regulation of the capsule wall formula, complicated process, etc., and achieve precise and controllable structure, regular shape, and heat transfer effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

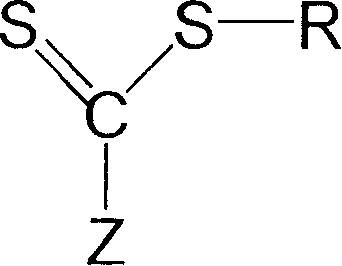

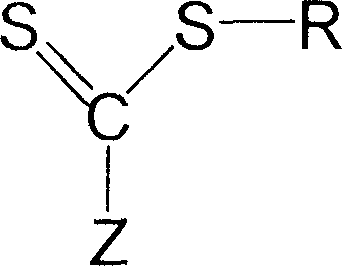

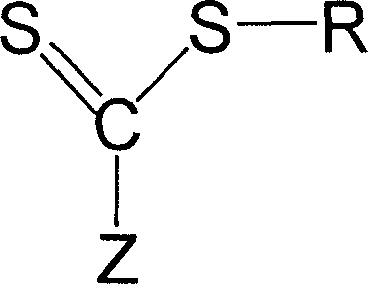

Method used

Image

Examples

Embodiment 1

[0039] 1) Mix 4 grams of 22°C phase change material, 0.5 grams of oligomer RAFT (1) and 16 grams of styrene to form an oil phase solution under magnetic stirring;

[0040] 2) adding 0.5 gram of ammonia solution (5% by mass) to 75 grams of water to form an aqueous phase solution;

[0041] 3) Mix the above oil phase solution and water phase solution, stir magnetically at 60°C for 30 minutes, and then use Ningbo Kesheng KS-600 ultrasonic pulverization for 15 minutes (70% output power);

[0042] 4) Move the fine emulsion into a reactor equipped with a mechanical stirring condensing reflux device, a nitrogen inlet, and a feeding port. After 30 minutes of deoxygenation with nitrogen, add a 68 ° C water bath, and simultaneously add an aqueous solution of potassium persulfate (0.16 g dissolved in 5 g water) to initiate polymerization, after the polymerization is completed, slowly cool to room temperature and discharge.

Embodiment 2

[0044] 1) Add 4 grams of 26°C phase change wax and 0.7 grams of oligomer RAFT (2) to 16 grams of hydroxyethyl methacrylate and 0.2 grams of ethylene glycol dimethacrylate mixture, and mix under magnetic stirring Uniform, forming an oil phase solution;

[0045] 2) Add 0.1 gram of sodium lauryl sulfate and 0.5 gram of ammonia solution into 75 grams of water, stir with slight heat to form a uniform aqueous phase solution;

[0046] 3) Mix the above oil phase solution and water phase solution, stir magnetically at 60°C for 30 minutes, and then use Ningbo Kesheng KS-600 ultrasonic pulverization for 15 minutes (70% output power);

[0047] 4) Move the fine emulsion into a reactor equipped with a mechanical stirring condensing reflux device, a nitrogen inlet, and a feeding port. After 30 minutes of deoxygenation with nitrogen, add a 68 ° C water bath, and simultaneously add an aqueous solution of potassium persulfate (0.16 g dissolved in 5 g water) to initiate polymerization, after th...

Embodiment 3

[0049] 1) Add 10 grams of 26°C phase change wax and 1.2 grams of oligomer RAFT (3) to the mixed monomer of 6 grams of styrene and 4 grams of methyl methacrylate, and mix evenly under magnetic stirring to form a uniform oil solution;

[0050] 2) Add 0.2 gram of sodium lauryl sulfate and 0.8 gram of ammonia solution (5%) into 75 grams of water, stir with slight heat to form a uniform aqueous phase solution;

[0051] 3) Mix the above oil phase solution and water phase solution, stir magnetically at 60°C for 30 minutes, and then use Ningbo Kesheng KS-600 ultrasonic pulverization for 15 minutes (70% output power);

[0052] 4) Move the fine emulsion into a reactor equipped with a mechanical stirring condensing reflux device, a nitrogen inlet, and a feeding port. After 30 minutes of deoxygenation with nitrogen, add a 68 ° C water bath, and simultaneously add an aqueous solution of ammonium persulfate (0.18 g dissolved in 5 g water) to initiate polymerization, after the polymerizatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com