A kind of conductive gas diffusion layer of fuel cell and its preparation method

A gas diffusion layer and fuel cell technology, applied in the field of electrochemistry, can solve the problems of easy damage to the pore structure of the microporous layer, lack of macroscopic pore structure and roughness, and reduce the diffusion performance of reactive gases, so as to avoid local agglomeration and Phase separation, composition and structure are precisely controllable, and the effect of avoiding damage to the electrolyte membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

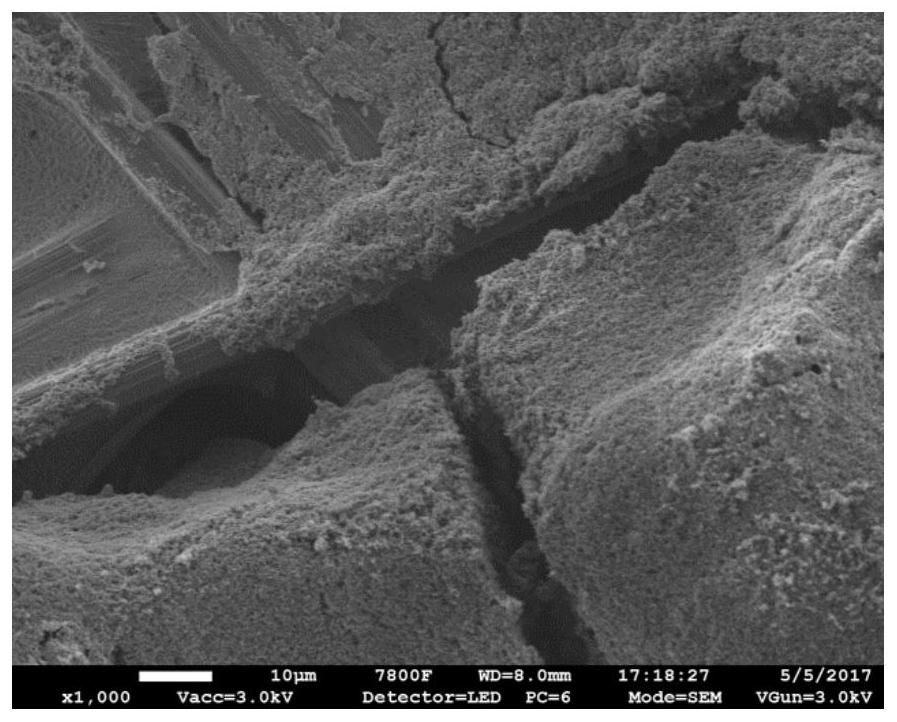

Embodiment 1

[0028] Cut out 5cm*5cm conductive carbon paper Toray060, then soak it in 5wt% PTFE aqueous solution (100ml), take it out after 5min and dry it with a hair dryer for later use; mix 50mg of XC-72R conductive carbon black with 200mg of PTFE aqueous solution ( Concentration is 5wt%) is dispersed in 50ml aqueous solution, after ultrasonic dispersion is even, add 10mg sodium dodecylsulfonate, continue to stir for 30min, this mixed solution is warmed up to 80 ℃ and continues mechanical stirring for 2 hours, cools down, and the obtained solution Filtration to obtain a wet filter cake with a water content of 40%, the filter cake is placed in 4ml of ethanol-water mixed solution for ultrasonic dispersion to obtain a microporous layer slurry, which is evenly coated on the hydrophobic treated surface by scraping. One side of the Toray060 carbon paper was dried in an oven, rolled and flattened, and then placed in a certain atmosphere for heat treatment. The treatment temperature was 350 ° C,...

Embodiment 2

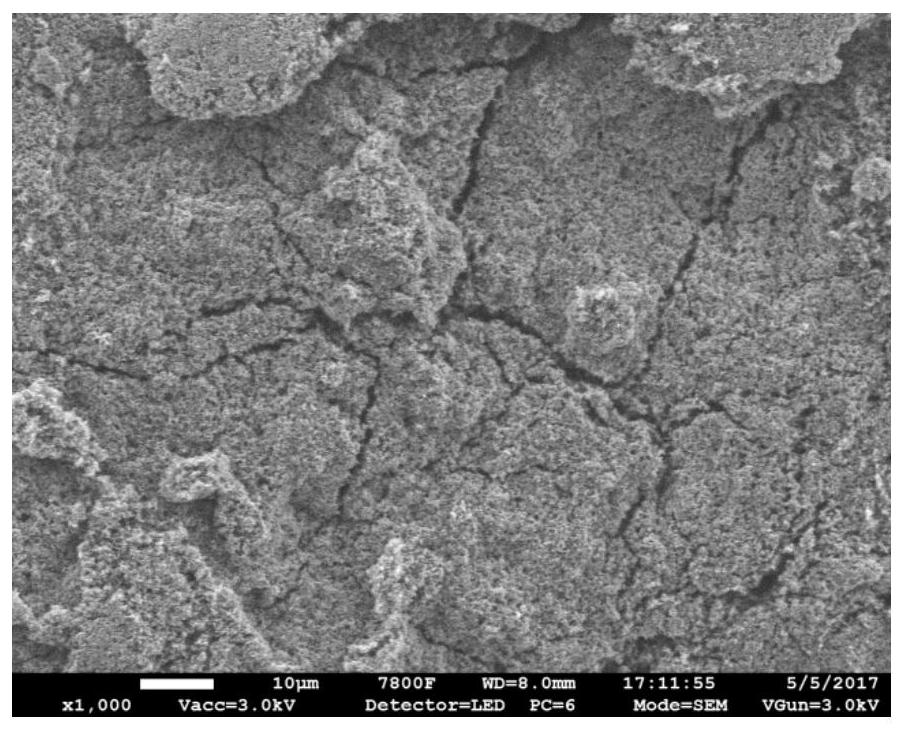

[0030] Cut out 5cm*5cm conductive carbon paper SGL 29AA, then soak it in 5wt% PTFE aqueous solution (80ml), take it out after 7min and dry it with a hair dryer for later use; mix 50mg of acetylene black conductive carbon black with 100mg of PTFE aqueous solution ( Concentration is 10wt%) dispersed in 50ml aqueous solution, after ultrasonic dispersion, add 12mg polyoxyethylene lauroyl ether, continue to stir for 30min, this mixed solution is warmed up to 60 ℃ and continues mechanical stirring for 1 hour, cool down, the obtained solution Filtration to obtain a wet filter cake with a water content of 40%, the filter cake is placed in 5ml ethanol-water mixed solution for ultrasonic dispersion to obtain a microporous layer slurry, which is evenly coated on the hydrophobic treated surface by scraping. One side of the SGL 29AA carbon paper, after drying the water in the oven, it is rolled and flattened, and then placed in a certain atmosphere for heat treatment, the treatment temperat...

Embodiment 3

[0032] Cut out a conductive carbon fiber cloth of 5cm*5cm, then soak it in 7wt% PTFE aqueous solution (100ml), take it out after 10min and dry it with a hair dryer for later use; mix 50mg of acetylene black conductive carbon black with 100mg of PTFE aqueous solution (concentration: 10wt%) was dispersed in 50ml of aqueous solution, after ultrasonic dispersion was uniform, 8mg of polyoxyethylene lauroyl ether was added, stirring was continued for 30min, the temperature of the mixed solution was raised to 60°C and mechanical stirring was continued for 1 hour, the temperature was lowered, and the resulting solution was filtered to obtain A wet filter cake with a water content of 30%, the filter cake is placed in 5ml of ethanol-water mixed solution for ultrasonic dispersion to obtain a microporous layer slurry, which is uniformly coated on the hydrophobic treated conductive One side of the carbon fiber cloth is rolled and flattened after drying the water in an oven, and then placed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com