Self-cleaning electrode for electrochemical biosensing

A sensing, electrochemical technology, applied in the field of electrochemical biosensing, can solve the problems of reducing detection efficiency, delaying detection time, biological damage, etc., and achieve the effect of great application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

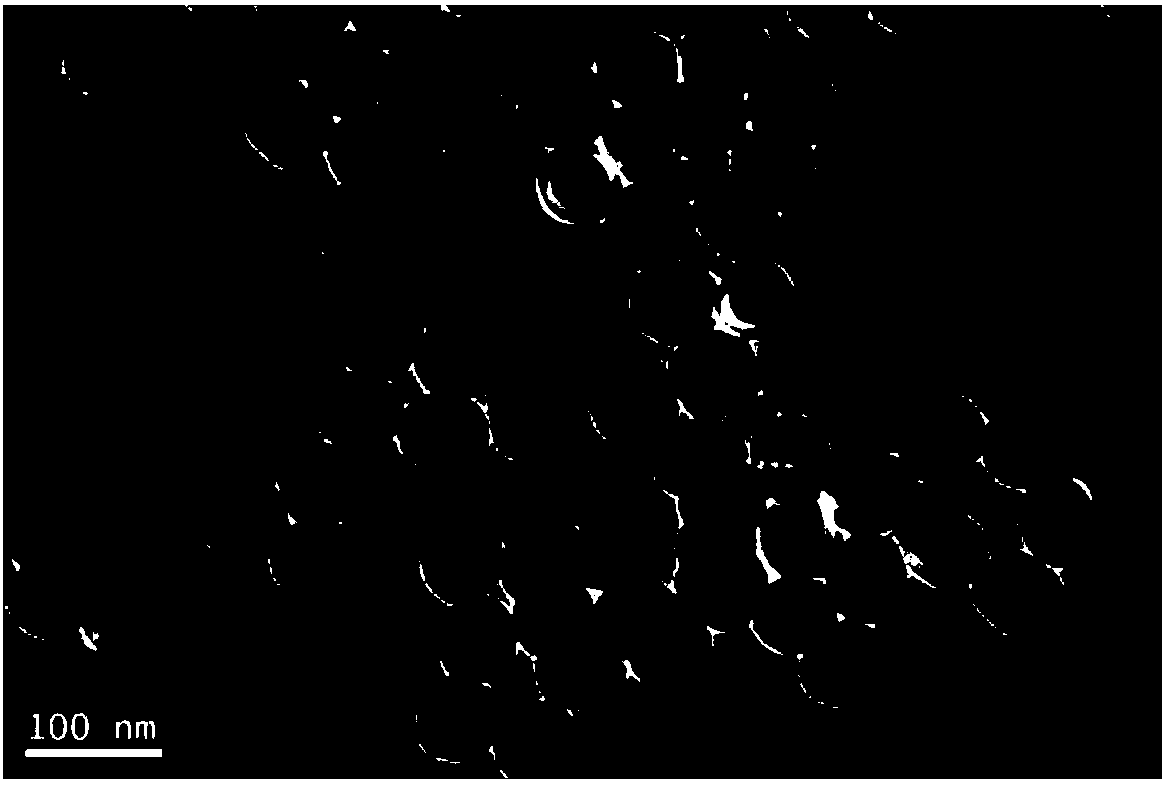

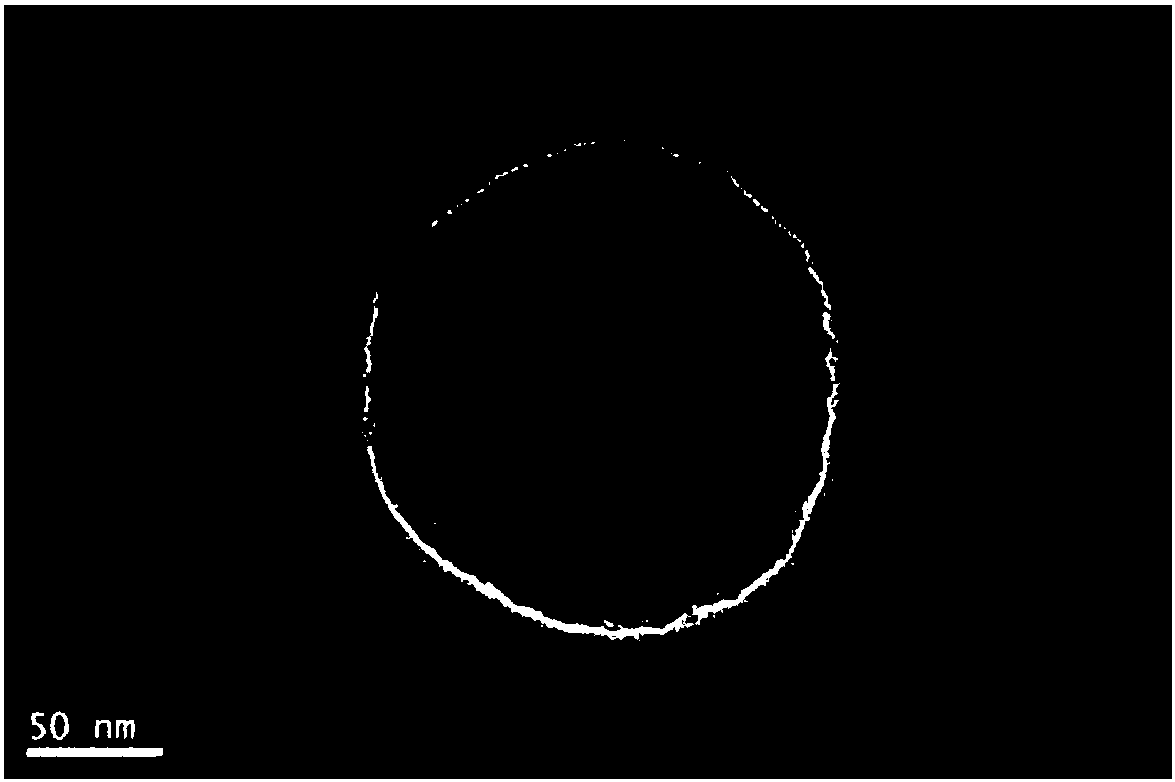

[0041] As a further preference, in the preparation method of the photosensitizer-upconversion nanoparticle composite particles, the specific steps of the step 1 are: weighing the YCl 3 ·6H 2 O, YbCl 3 ·6H 2 O and ErCl 3 ·6H 2 O, under an argon atmosphere, heat to 160°C to remove water in the system, after cooling to room temperature, add oleic acid and oleylamine as solvents, heat the system to 150-200°C to obtain a transparent and uniform solution 1; weigh the NaOH and NH 4 F, dissolved in methanol to obtain solution 2; quickly add the solution 2 to the solution 1, stir evenly, heat the system to 100°C to remove the methanol in the system, then quickly heat the system to 300°C, and react for 60 -90 min, cooling to room temperature; adding acetone to the reacted solution to precipitate product 1, washing the product 1 with a mixture of ethanol and methanol to obtain the up-converting nanoparticles. It should be noted that the up-conversion nanoparticles prepared by adopt...

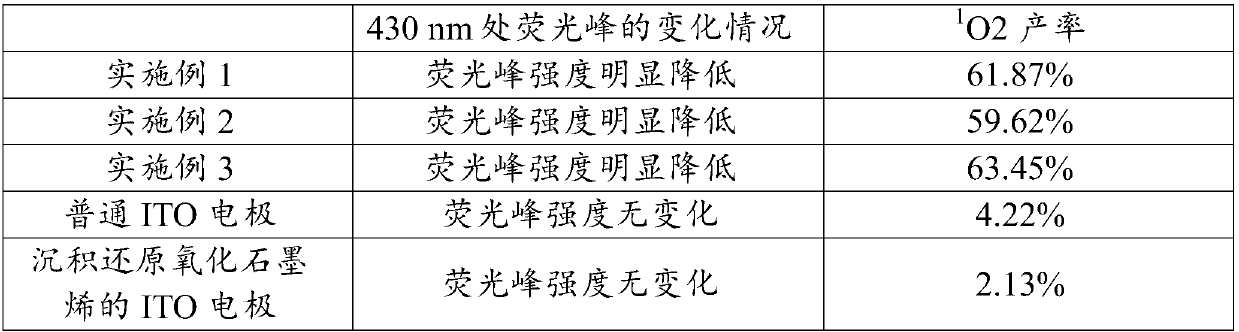

Embodiment 1

[0047] With the ITO electrode as the conductive substrate, the ITO electrode was placed in a 0.1mg / mL reduced graphene oxide solution, a voltage of -1.0V was applied to the ITO electrode, and the deposition was continued for 1000s, so that a layer of reduced graphene oxide was deposited on the surface of the ITO electrode, and then Place the deposited ITO electrode in an aqueous solution of 8mg / mL photosensitizer-upconversion nanoparticle composite particles, apply a voltage of -1.0V, and continue to deposit for 1000s, so that a layer of photosensitizer-upconversion nanoparticle composite is deposited on the surface. particles to obtain self-cleaning electrodes for electrochemical biosensing.

[0048] Wherein, the preparation method of the photosensitizer-up-conversion nanoparticle composite particle is:

[0049] Step 1: Prepare NaYF 4 upconverting nanoparticles

[0050] (1) Weigh 0.5mmol YCl 3 ·6H 2 O, 0.1mmol YbCl 3 ·6H 2 O and 0.01 mmol ErCl 3 ·6H 2 O, under an argo...

Embodiment 2

[0062] With the ITO electrode as the conductive substrate, the ITO electrode was placed in a 0.55 mg / mL reduced graphene oxide solution, a voltage of -1.0V was applied to the ITO electrode, and the deposition was continued for 1500 s, so that a layer of reduced graphene oxide was deposited on the surface of the ITO electrode, and then Place the deposited ITO electrode in an aqueous solution of 8mg / mL photosensitizer-upconversion nanoparticle composite particles, apply a voltage of -1.0V, and continue to deposit for 1500s, so that a layer of photosensitizer-upconversion nanoparticle composite is deposited on the surface. particles to obtain self-cleaning electrodes for electrochemical biosensing.

[0063] Wherein, the preparation method of the photosensitizer-up-conversion nanoparticle composite particle is:

[0064] Step 1: Prepare NaYF 4 upconverting nanoparticles

[0065] (1) Weigh 0.75mmol YCl 3 ·6H 2 O, 1.05mmol YbCl 3 ·6H 2 O and 0.03 mmol ErCl 3 ·6H 2 O, under an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com