Optical coupling microwave catalytic system applied to biomass pyrolysis and biomass pyrolysis equipment

A technology of biomass pyrolysis and microwave catalysis, which is applied in the direction of catalytic treatment of combustible gases, catalyst activation/preparation, preparation of liquid hydrocarbon mixtures, etc., to achieve efficient utilization, improve quality, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

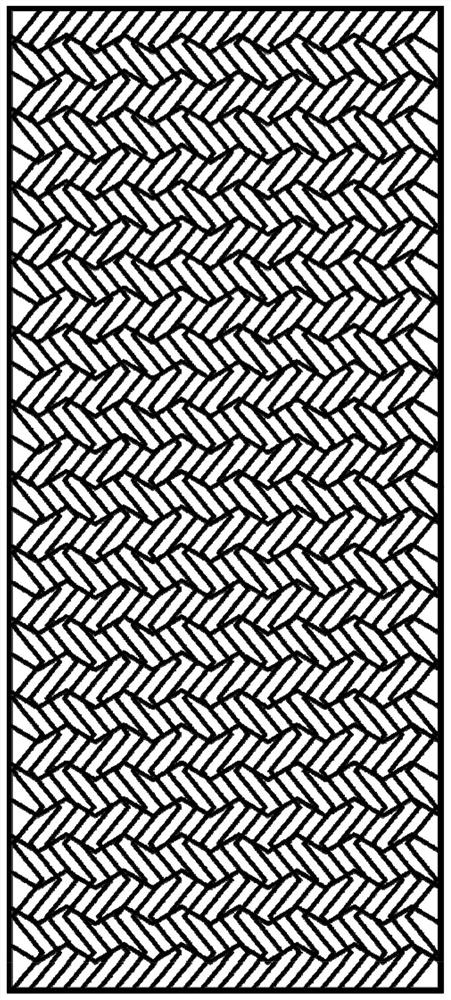

[0042] More specifically, the catalytic plate is prepared by loading a layer of deoxidation catalyst on the surface of porous foam ceramics, and then dispersing and loading a layer of photocatalyst on the outer layer of the deoxidation catalyst. The specific preparation method is as follows:

[0043] (1) Preparation of porous ceramic foam: After mixing SiC and TiC in proportion, mix them by low-speed ball milling for 0.5-2 hours to prepare ceramic aggregate; mix ceramic aggregate and aluminum dihydrogen phosphate according to 1:1-4:1 and add kaolin and Prepare the slurry with deionized water; stir and mix the slurry at room temperature for 12-48 hours; add deionized water according to the solid content of the slurry at 60-80%.

[0044] (2) After cutting the polyurethane foam into the required shape and size, soak it with 8%-20% sodium hydroxide solution and rub it for 1-3 hours, then wash it and then impregnate it with 0.5%-3% sodium carboxymethyl cellulose solution Standby afte...

Embodiment 1

[0054] In the catalytic plate preparation step (1), the ratio of SiC to TiC is 1:0, the ball milling time is 1 hour, the ratio of ceramic aggregate to aluminum dihydrogen phosphate is 2:1, the solid content of the slurry is 80%, and the time for trapping It was 24 hours; the sodium hydroxide concentration was 16% in the step (2), the soaking time was 2 hours, the sodium carboxymethyl cellulose solution concentration was 2%, and the soaking time was 2 hours; the preform was dried at room temperature in the step (4) After 24 hours, dry in an oven for 12 hours, and the final temperature of calcination is 1200°C; the compound raw materials in step (5) are magnesium oxide and aluminum oxide mixed at 10:1 and ball milled for 1 hour, 0.2 parts of polyvinyl alcohol, carboxymethyl cellulose 0.5 part, 0.5 part of alkaline silica sol, the solid content rate of the slurry is 55%; the drying time at room temperature is 18 hours each time after the ceramic foam is slurryed in the step (6), a...

Embodiment 2

[0059] In the catalytic plate preparation step (1), the ratio of SiC to TiC is 1:0, the ball milling time is 1 hour, the ratio of ceramic aggregate to aluminum dihydrogen phosphate is 2:1, the solid content of the slurry is 80%, and the time for trapping It was 24 hours; the sodium hydroxide concentration was 16% in the step (2), the soaking time was 2 hours, the sodium carboxymethyl cellulose solution concentration was 2%, and the soaking time was 2 hours; the preform was dried at room temperature in the step (4) After 24 hours, dry in an oven for 12 hours, and the final temperature of calcination is 1200°C; the compound raw materials in step (5) are magnesium oxide, calcium oxide and aluminum oxide mixed and ball milled for 1 hour according to 5:5:1, 0.2 parts of polyvinyl alcohol, 0.5 part of carboxymethyl cellulose, 0.5 part of alkaline silica sol, the solid content rate of the slurry is 55%; the drying time at room temperature is 18 hours each time after the foam ceramics ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com