Self-cleaning electrodes for electrochemical biosensing

A sensing, electrochemical technology, applied in the field of electrochemical biosensing, can solve the problems of reduced detection efficiency, biological damage, poor ultraviolet light penetration effect, etc., and achieves great application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

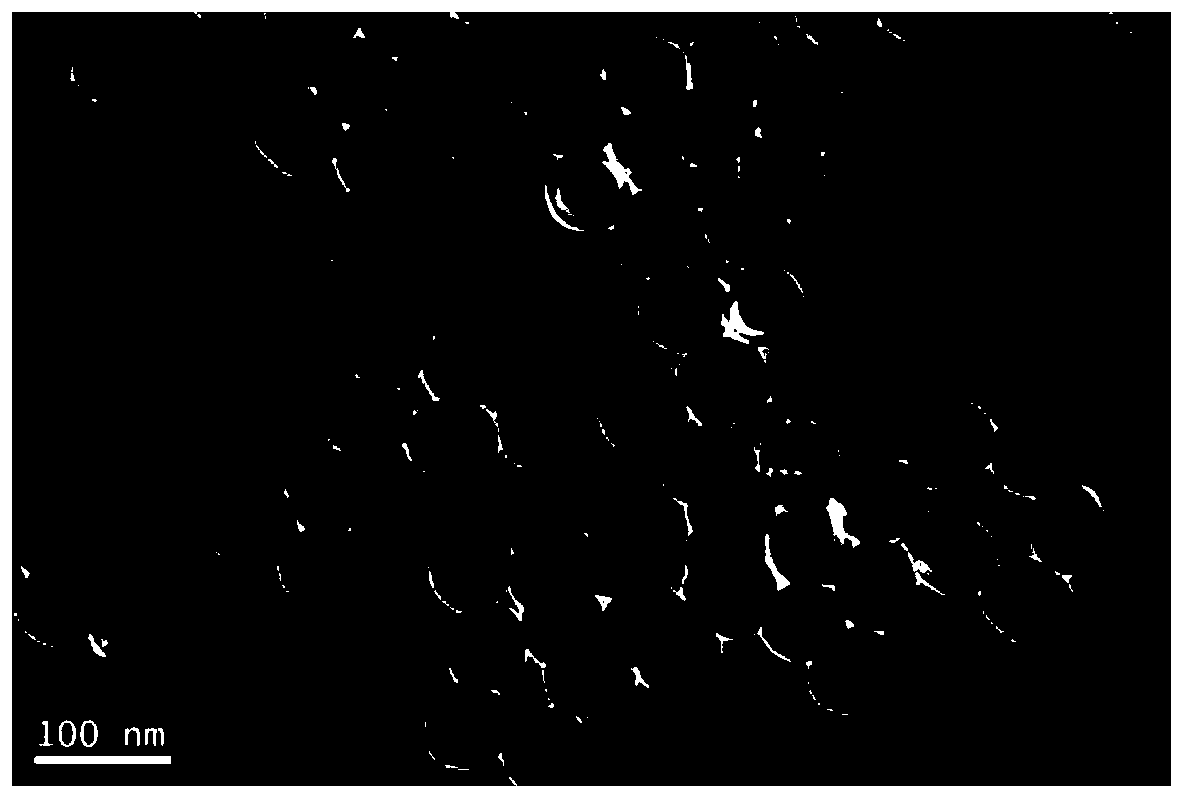

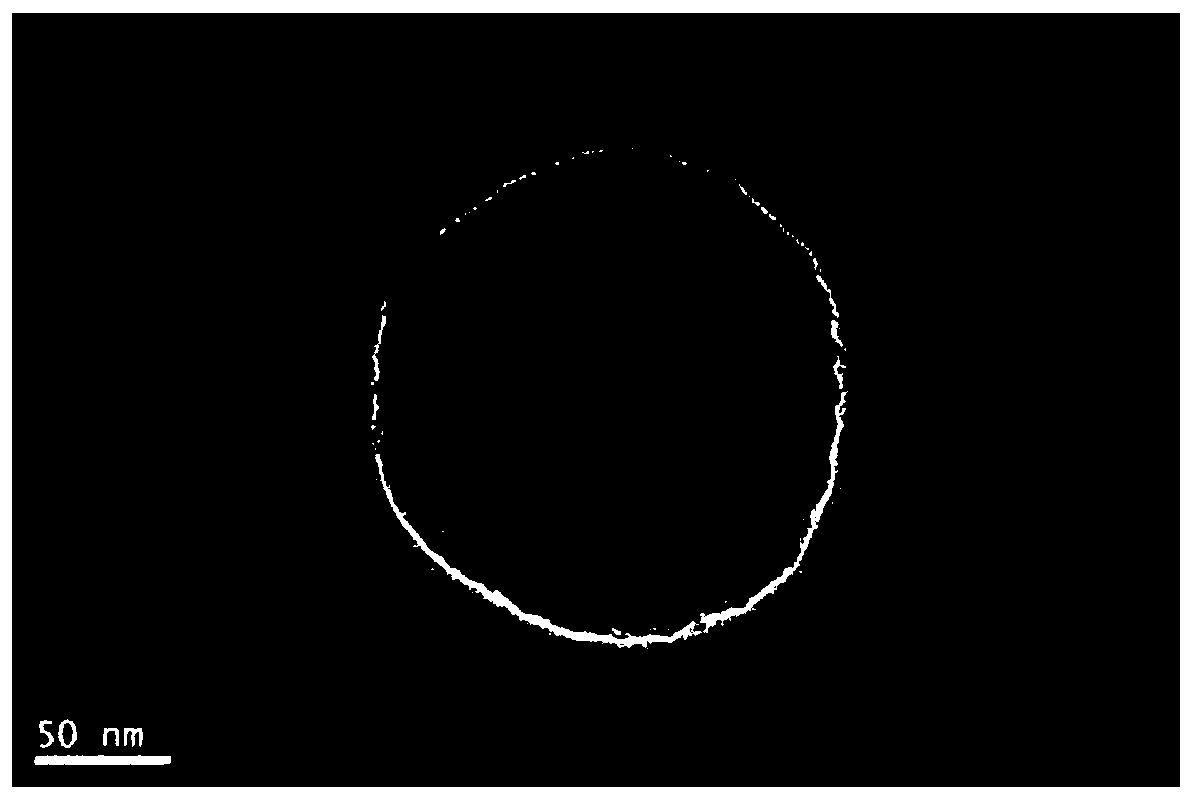

[0041] As a further preference, in the preparation method of the photosensitizer-upconversion nanoparticle composite particles, the specific steps of the step 1 are: weighing the YCl 3 ·6H 2 O, YbCl 3 ·6H 2 O and ErCl 3 ·6H 2 O, under an argon atmosphere, heat to 160°C to remove water in the system, after cooling to room temperature, add oleic acid and oleylamine as solvents, heat the system to 150-200°C to obtain a transparent and uniform solution 1; weigh the NaOH and NH 4 F, dissolved in methanol to obtain solution 2; quickly add the solution 2 to the solution 1, stir evenly, heat the system to 100°C to remove the methanol in the system, then quickly heat the system to 300°C, and react for 60 -90 min, cooling to room temperature; adding acetone to the reacted solution to precipitate product 1, washing the product 1 with a mixture of ethanol and methanol to obtain the up-converting nanoparticles. It should be noted that the up-conversion nanoparticles prepared by adopt...

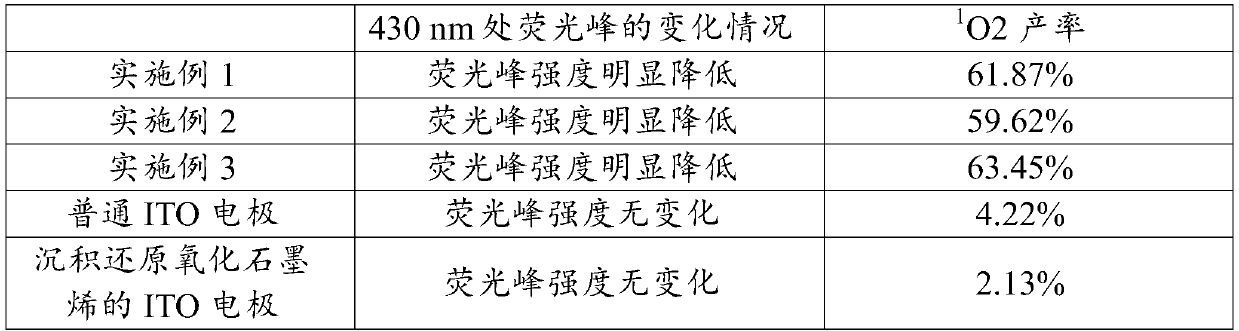

Embodiment 1

[0047] With the ITO electrode as the conductive substrate, the ITO electrode was placed in a 0.1mg / mL reduced graphene oxide solution, a voltage of -1.0V was applied to the ITO electrode, and the deposition was continued for 1000s, so that a layer of reduced graphene oxide was deposited on the surface of the ITO electrode, and then Place the deposited ITO electrode in an aqueous solution of 8mg / mL photosensitizer-upconversion nanoparticle composite particles, apply a voltage of -1.0V, and continue to deposit for 1000s, so that a layer of photosensitizer-upconversion nanoparticle composite is deposited on the surface. particles to obtain self-cleaning electrodes for electrochemical biosensing.

[0048] Wherein, the preparation method of the photosensitizer-up-conversion nanoparticle composite particle is:

[0049] Step 1: Prepare NaYF 4 upconverting nanoparticles

[0050] (1) Weigh 0.5mmol YCl 3 ·6H 2 O, 0.1mmol YbCl 3 ·6H 2 O and 0.01 mmol ErCl 3 ·6H 2 O, under an argo...

Embodiment 2

[0062] With the ITO electrode as the conductive substrate, the ITO electrode was placed in a 0.55 mg / mL reduced graphene oxide solution, a voltage of -1.0V was applied to the ITO electrode, and the deposition was continued for 1500 s, so that a layer of reduced graphene oxide was deposited on the surface of the ITO electrode, and then Place the deposited ITO electrode in an aqueous solution of 8mg / mL photosensitizer-upconversion nanoparticle composite particles, apply a voltage of -1.0V, and continue to deposit for 1500s, so that a layer of photosensitizer-upconversion nanoparticle composite is deposited on the surface. particles to obtain self-cleaning electrodes for electrochemical biosensing.

[0063] Wherein, the preparation method of the photosensitizer-up-conversion nanoparticle composite particle is:

[0064] Step 1: Prepare NaYF 4 upconverting nanoparticles

[0065] (1) Weigh 0.75mmol YCl 3 ·6H 2 O, 1.05mmol YbCl 3 ·6H 2 O and 0.03 mmol ErCl 3 ·6H 2 O, under an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com