Machine-vision-based intelligent cutter lifting system of shearing machine and realization method thereof

A machine vision and shearing machine technology, applied in sequence/logic controller program control, instruments, scientific instruments, etc., can solve problems such as difficulty in guaranteeing product quality, influence of fabric processing style, and no lifting of the knife when sewing. Achieve the effect of improving the overall intelligence of the equipment, ensuring consistent product quality, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

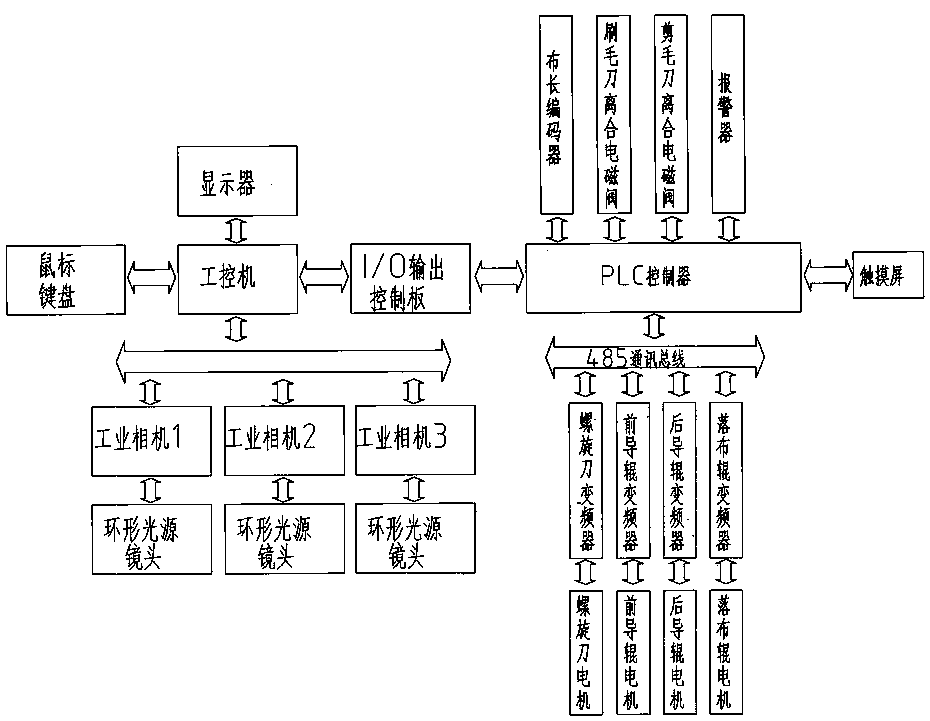

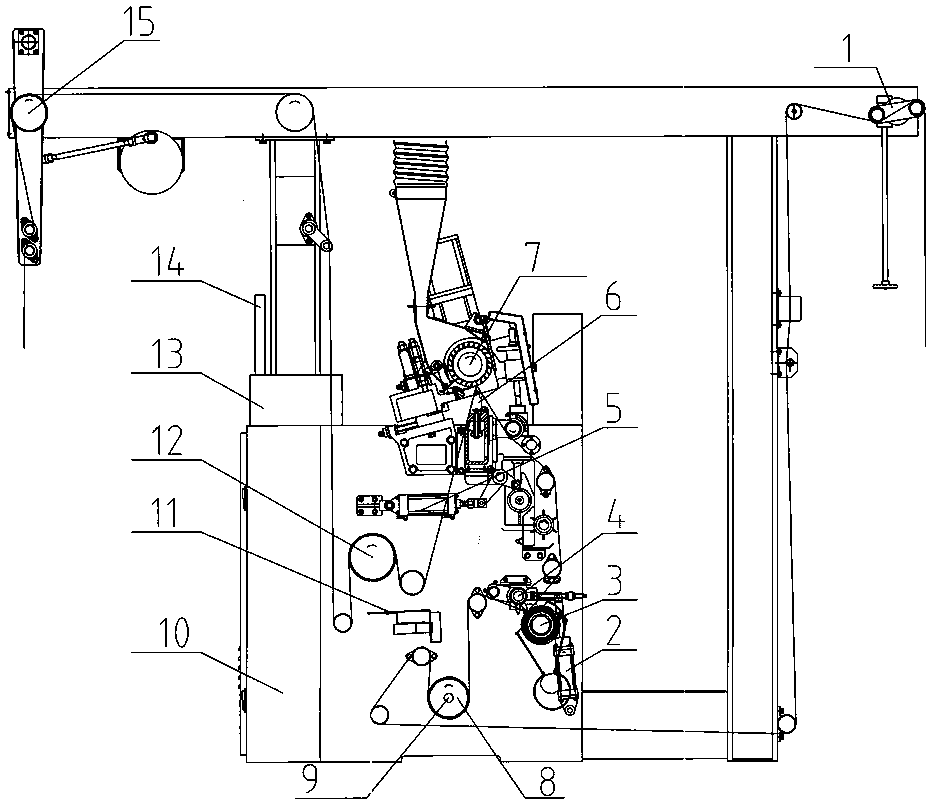

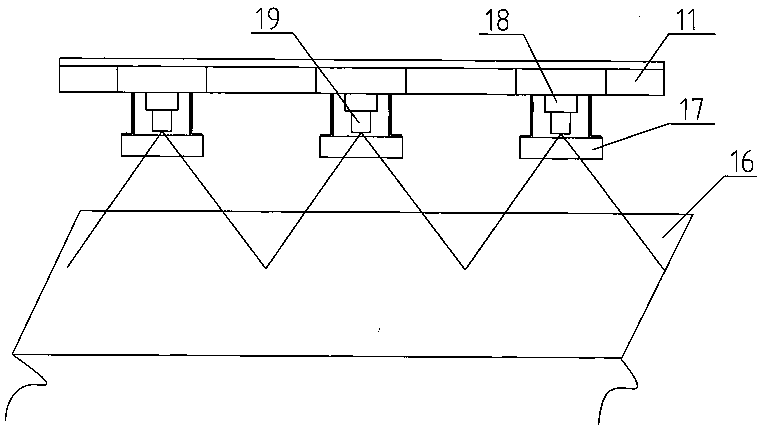

[0021] as attached figure 1 , figure 2 and image 3 As shown, a shearing machine intelligent knife lifting system based on machine vision includes a touch screen, PLC controller, alarm, and a screw knife connected to the screw knife motor, the front guide roller motor, the rear guide roller motor, and the cloth drop roller motor respectively. Frequency converter, frequency converter for front guide roller, frequency converter for rear guide roller, frequency converter for cloth doffing roller, cloth length encoder set on the shaft of the front guide roll, brush knife roller and its clutch device set on the frame, set on the frame The shearing knife and its lifting device and the cloth guide system arranged on the frame, wherein the clutch device includes the brush knife clutch cylinder 2 and the brush knife clutch electromagnetic valve, and the knife lifting device includes the shearing knife clutch solenoid valve and the shearing knife clutch cylinder 5 , the cloth guide s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com